Automobile factory wastewater treatment method and use

A treatment method, the technology of the automobile factory, applied in the direction of waste paint treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of refractory COD, difficult to handle, high toxicity, etc., and achieve the effect of thorough decontamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

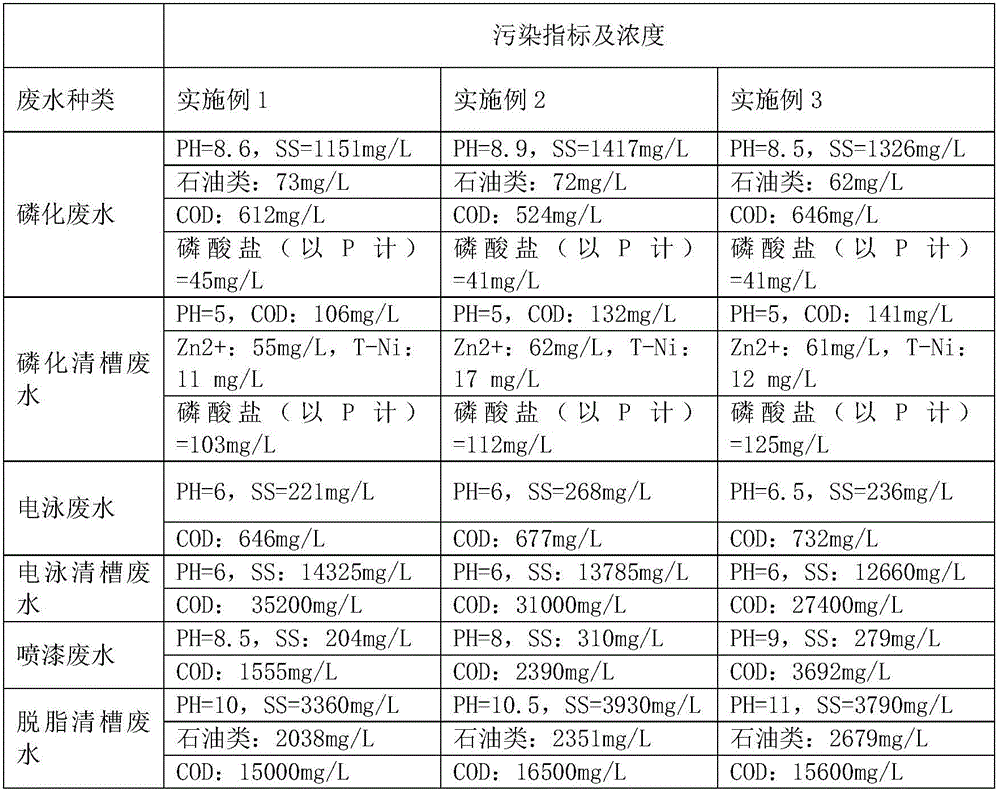

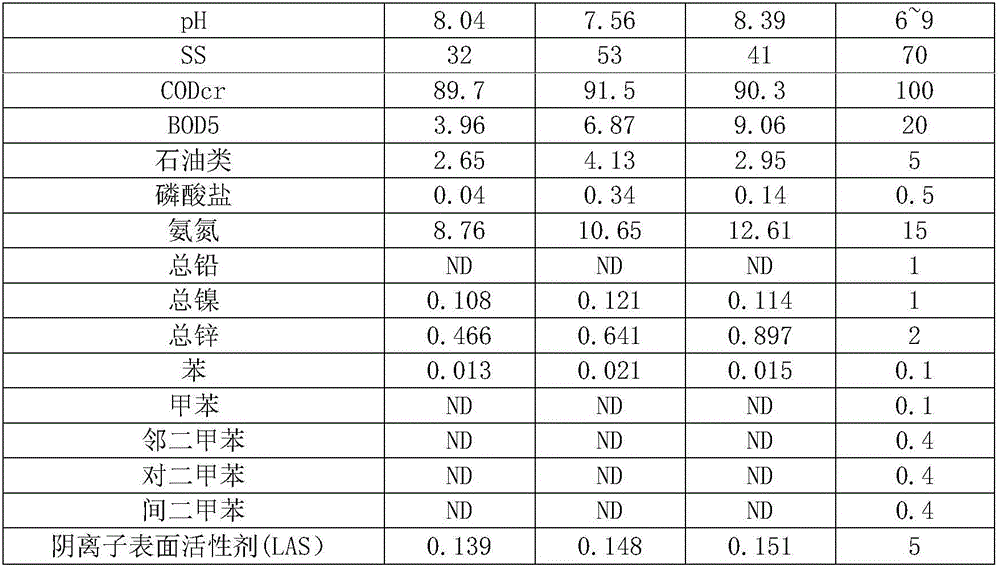

Embodiment 1

[0037] Follow the steps below to treat automotive painting wastewater:

[0038] 1) Phosphating wastewater pretreatment

[0039] The phosphating waste water is homogenized and equalized in the regulating tank, and then lifted to the pH regulating tank of the phosphating nickel-containing waste water, and lime milk and heavy metal scavenger are automatically added to adjust the pH value of the waste water to between 10-11. After fully stirring and reacting, enter the coagulation reaction tank, add coagulant PFC and flocculant polyacrylamide PAM-, after mechanical stirring coagulation, flocculation reaction, flow into the phosphating wastewater inclined plate sedimentation tank, use gravity to separate, and then go up The clear liquid flows into the detection water tank, and after the detection of nickel ions in the water reaches the design standard, it flows into the comprehensive waste water pool;

[0040] If it is detected that the content of nickel ions in the water exceeds ...

Embodiment 2

[0056] Follow the steps below to treat automotive painting wastewater:

[0057] 1) Phosphating wastewater pretreatment

[0058] Homogenization and equalization are carried out in the phosphating wastewater adjustment tank, and then it is lifted to the pH adjustment tank of phosphating nickel-containing wastewater, and lime milk and heavy metal scavenger are automatically added to adjust the pH value of the wastewater to between 10-11. After fully stirring and reacting, enter the coagulation reaction tank, add coagulant PFS and flocculant polyacrylamide PAM+, after mechanical stirring coagulation and flocculation reaction, it flows into the phosphating wastewater inclined plate sedimentation tank, and after gravity separation, the supernatant The liquid flows into the detection water tank, and after the detection of nickel ions in the water reaches the design standard, it flows into the comprehensive waste water pool;

[0059] If it is detected that the content of nickel ions ...

Embodiment 3

[0075] Follow the steps below to treat automotive painting wastewater:

[0076] 1) Phosphating wastewater pretreatment

[0077] Homogenization and equalization are carried out in the phosphating wastewater adjustment tank, and then it is lifted to the pH adjustment tank of phosphating nickel-containing wastewater, and lime milk and heavy metal scavenger are automatically added to adjust the pH value of the wastewater to between 10-11. After fully stirring and reacting, enter the coagulation reaction tank, add coagulant PAC and non-ionic PAM, flow into the phosphating wastewater inclined plate sedimentation tank after mechanical stirring coagulation and flocculation reaction, and use gravity to separate, and the supernatant flows into The water tank is tested, and after the detection of nickel ions in the water reaches the design standard, it flows into the comprehensive waste water pool;

[0078] If it is detected that the content of nickel ions in the water exceeds the stand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com