Ultracrystallite anti-glare frosting solution for colored glass and frosting method for colored glass

A technology of colored glass and ultrafine crystals, which is applied in the field of chemical processing, can solve the problems of non-uniform frosting particle size, poor wear resistance and durability, and low stress resistance, and achieve environmental protection, good fastness, and durability. The effect of high stress intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

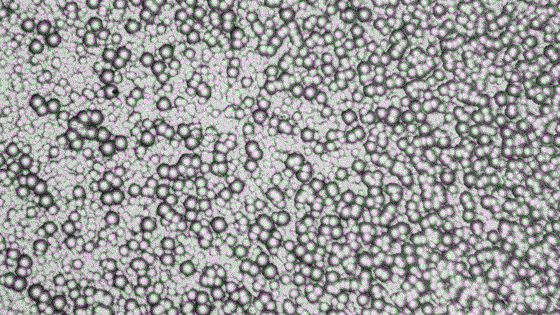

[0033] Take sodium fluoride, potassium fluoride, ammonium sulfate, and potassium sulfate to make A powder in a weight ratio of 8.0:6.0:4.0:1.0, and make B powder with calcium fluoride and barium sulfate in a weight ratio of 5.0:5.0. A powder, B powder and ultrapure water are made into a solution in a weight ratio of 75:10:1000, and the pH is adjusted to 3.0 with sulfuric acid to make a frosting solution. Put the pretreated glass sample into the frosting solution, take it out after frosting for 2.0min under the condition of 25°C magneton rotation speed 120r / min, wash it with pure water and dry it, measure its roughness Ra and gloss Gs, Taking microscope pictures such as figure 1 .

[0034] Pretreatment steps: glass sample—washing with chromic acid lotion—washing with ultrapure water—drying—applying protective film.

[0035] Such as figure 1 , it was found that the surface of the frosted glass sample was not uniform, and the size gap of ultrafine crystal grains was too larg...

Embodiment 2

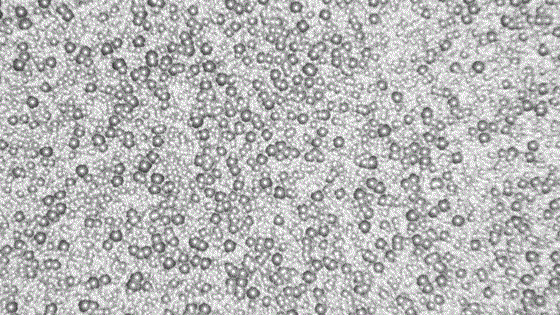

[0046] ① Take sodium fluoride, potassium fluoride, ammonium sulfate, and potassium sulfate to make A powder in a weight ratio of 8.0:5.0:3.0:1.0, and make B powder with calcium fluoride and barium sulfate in a weight ratio of 6.0:5.0. A powder, B powder and ultrapure water are made into a solution at a weight ratio of 75:11:1000, and the pH is adjusted to 3.0 with sulfuric acid to make a frosting solution. Put the pretreated glass sample into the frosting solution, take it out after frosting for 2.0min under the condition of 25°C magneton rotation speed 120r / min, wash it with pure water and dry it, measure its roughness Ra and gloss Gs, Taking microscope pictures such as figure 2 .

[0047] Roughness index: Ra 1 =0.211μm Ra 2 =0.245μm Ra 3 =0.268μm

[0048] Ra 4 =0.209μm Ra 5 =0.256μm Ra 6 =0.259μm

[0049] Ra 7 =0.299μm

[0050] Ra precision: RSD=0.127

[0051] Gloss index: Gs 1 =20.1GU Gs 2 =25.0GU Gs 3 =28.3GU

[0052] Gs 4 =20.2GU Gs 5 =26.0GU Gs 6 =26.2G...

Embodiment 3

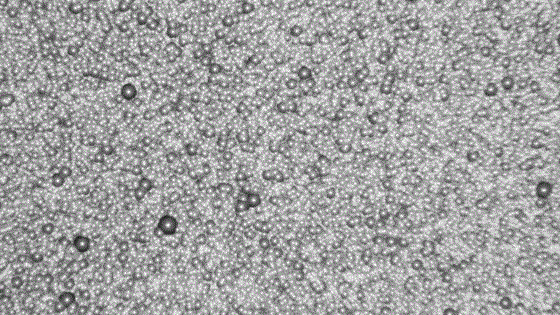

[0066] ① Take sodium fluoride, potassium fluoride, ammonium sulfate, and potassium sulfate in a weight ratio of 8.0:3.0:3.0:1.0 to make A powder, and calcium fluoride and barium sulfate in a weight ratio of 6.0:5.0 to make B powder. A powder, B powder and ultrapure water are made into a solution at a weight ratio of 75:11:1000, and the pH is adjusted to 3.0 with sulfuric acid to make a frosting solution. Put the pretreated glass sample into the frosting solution, take it out after 2.5 minutes of frosting under the condition of 25°C magneton rotation speed 120r / min, wash it with pure water and dry it, measure its roughness Ra and gloss Gs, Taking microscope pictures such as Figure 5 .

[0067] Roughness index: Ra 1 =0.261μm Ra 2 =0.275μm Ra 3 =0.276μm

[0068] Ra 4 =0.266μm Ra 5 =0.268μm Ra 6 =0.273μm

[0069] Ra 7 =0.310μm

[0070] Ra precision: RSD=0.0583

[0071] Gloss index: Gs 1 =22.0GU Gs 2 =21.2GU Gs 3 =18.1GU

[0072] Gs 4 =23.1GU Gs 5 =22.3GU Gs 6 =...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com