Non-shrink concrete

A concrete and fly ash technology, applied in the field of building concrete, can solve the problems of affecting the construction progress, concrete cracking, brittleness, etc., and achieve the effect of slowing down the heat generation speed, slowing down the hydration reaction speed, and increasing the limited expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] First prepare the expansion agent, take 190kg of anhydrite, 60kg of magnesium oxide, 70kg of calcium oxide, 20kg of tartaric acid, 40kg of sodium silicate, 70kg of sodium tripolyphosphate, 60kg of sodium gluconate, and 10kg of sodium citrate. 270 mesh sieve, take powder, and mix each powder material evenly to obtain expansion agent.

[0014] To prepare shrinkage-resistant concrete, take 3,500kg of sulphoaluminate cement, 25,000kg of medium sand, 16,000kg of fly ash, 750kg of methyl cellulose, and 50kg of aluminum nitride powder and mix them evenly, and add 250kg of expansion agent to obtain shrinkage-resistant concrete.

[0015] When preparing mortar, stir in three steps, ① firstly mix sulphoaluminate cement, medium sand, fly ash, methyl cellulose, aluminum nitride powder evenly, ② add 2500kg water and stir repeatedly, ③ then add The expansion agent is stirred and mixed evenly to obtain shrinkage-resistant concrete mortar; then pouring construction is carried out.

Embodiment 2

[0017] To prepare shrinkage-resistant concrete, take 3500kg of sulphoaluminate cement, 2500kg of medium sand, 1540kg of fly ash, 75kg of methyl cellulose, 5kg of aluminum nitride powder, and 40kg of quartz powder, and mix them evenly. Shrinkage resistant concrete.

[0018] When preparing the mortar, stir in three steps, ① first mix sulfoaluminate cement, medium sand, fly ash, methyl cellulose, aluminum nitride powder, and quartz powder evenly, ② add 2500kg of water and stir repeatedly, ③Then add expansion agent and mix well to obtain shrinkage-resistant concrete mortar.

Embodiment 3

[0020] First prepare the expansion agent, take 200kg of anhydrite, 65kg of magnesium oxide, 75kg of calcium oxide, 25kg of tartaric acid, 45kg of sodium silicate, 75kg of sodium tripolyphosphate, 65kg of sodium gluconate, and 15kg of sodium citrate. 270 mesh sieve, take powder, and mix each powder material evenly to obtain expansion agent.

[0021] Then prepare anti-shrinkage concrete, take 3800kg of sulphoaluminate cement, 2700kg of medium sand, 1800kg of fly ash, 100kg of methyl cellulose, 7kg of aluminum nitride powder and mix well, and add 275kg of expansion agent to obtain anti-shrinkage concrete.

[0022] When preparing the mortar, stir in three steps, ① first mix the sulphoaluminate cement, medium sand, fly ash, methyl cellulose, aluminum nitride powder evenly, ② add 2700kg of water and stir repeatedly, ③ then add The expansion agent is stirred and mixed evenly to obtain shrinkage-resistant concrete mortar; then pouring construction is carried out.

PUM

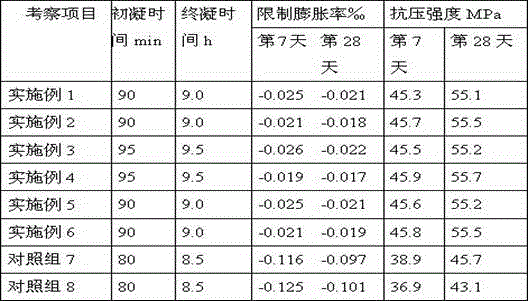

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com