A kind of modified dolomite powder-based mineral admixture and preparation method thereof

A technology of mineral admixture and dolomite powder, applied in the field of concrete, can solve the problems of poor fluidity and strength drop of concrete, and achieve the effects of reducing durability reduction, improving fluidity, and improving workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The percentage by weight of each component of a modified dolomite powder-based mineral admixture is: Blaine specific surface area is 397m 2 / kg of dolomite powder (CaCO 3 · MgCO 3 The mass percentage content is not less than 75%) 60%; 0.045mm square hole sieve residue is 10% I grade fly ash 17%; S95 grade slag powder 17%; sodium bentonite 6%. The weighed dolomite powder, fly ash, mineral powder and bentonite are uniformly mixed in a mixer to obtain the modified dolomite powder-based mineral admixture DI.

Embodiment 2

[0036] The percentage by weight of each component of a modified dolomite powder-based mineral admixture is: Blaine specific surface area is 397m 2 / kg of dolomite powder (CaCO 3 · MgCO 3 The mass percentage content is not less than 75%) 50%; 0.045mm square hole sieve is 10% Class I fly ash 20%; S95 grade slag powder 20%; sodium bentonite 10%. The weighed dolomite powder, fly ash, mineral powder and bentonite are uniformly mixed in a mixer to obtain the modified dolomite powder-based mineral admixture DII.

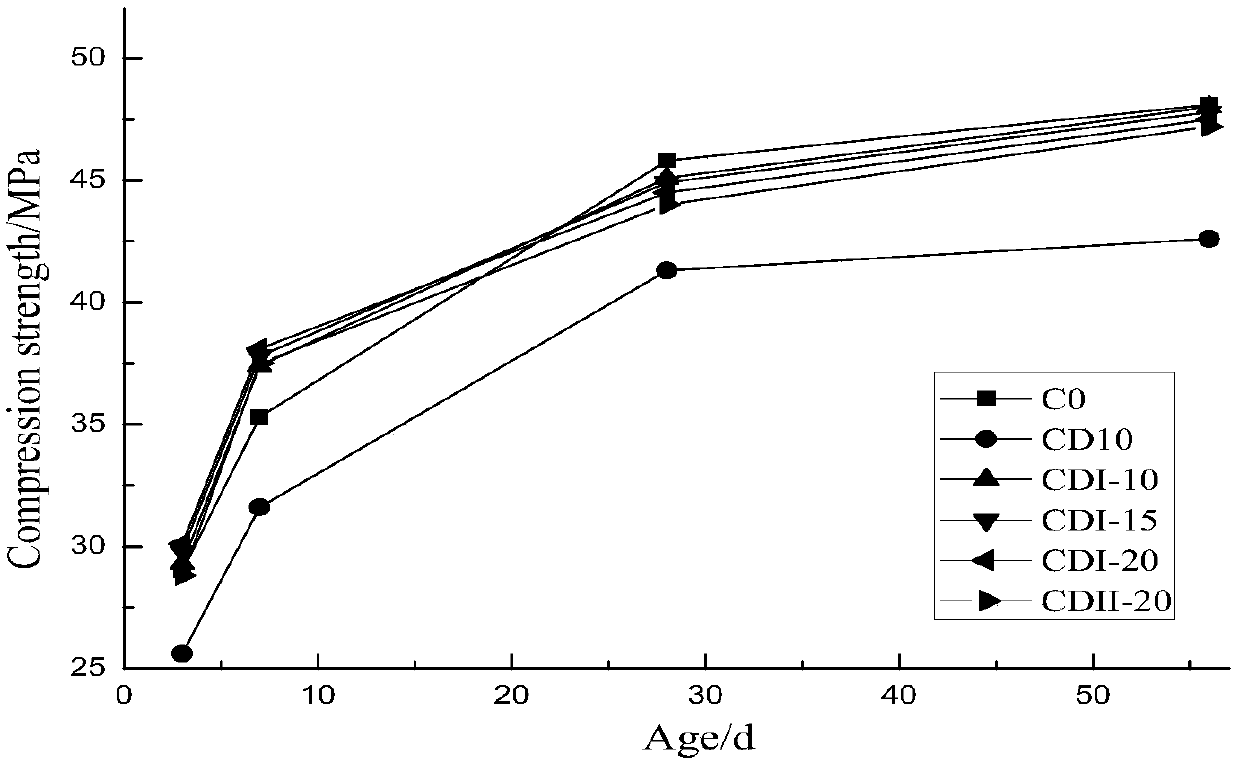

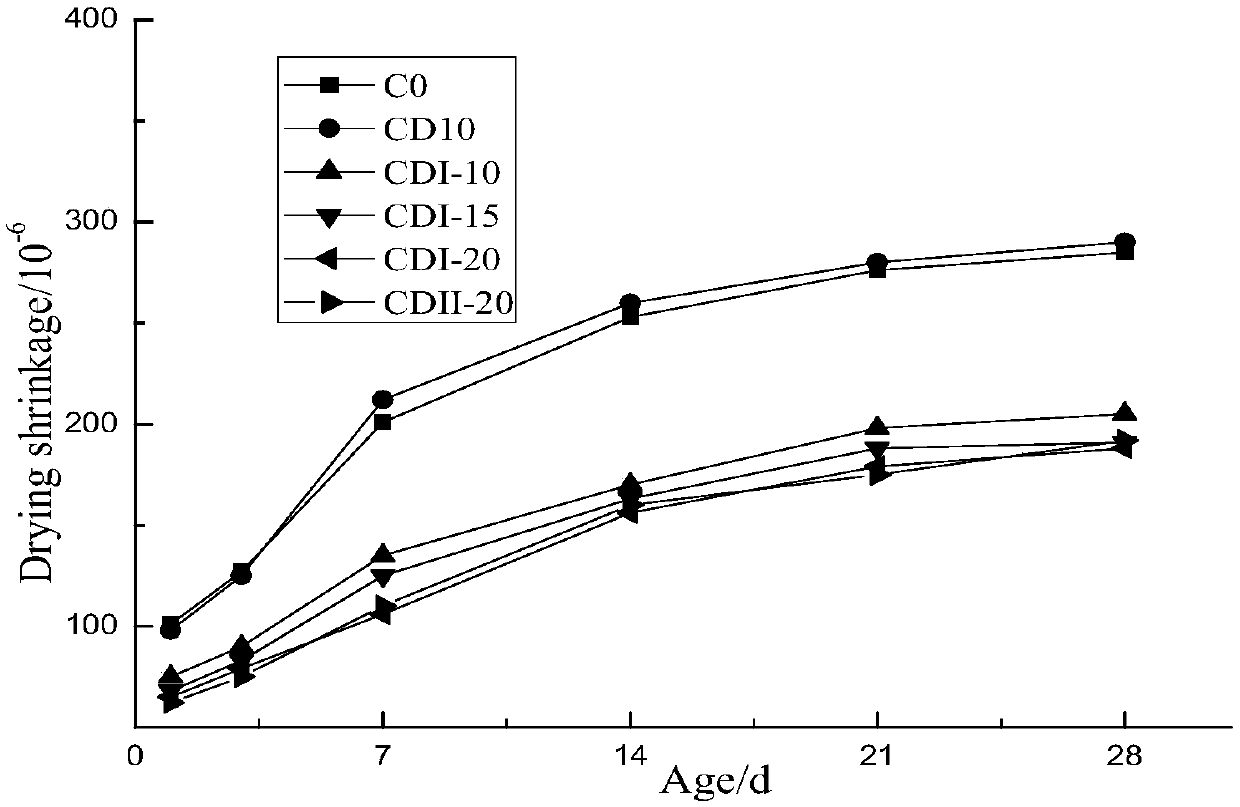

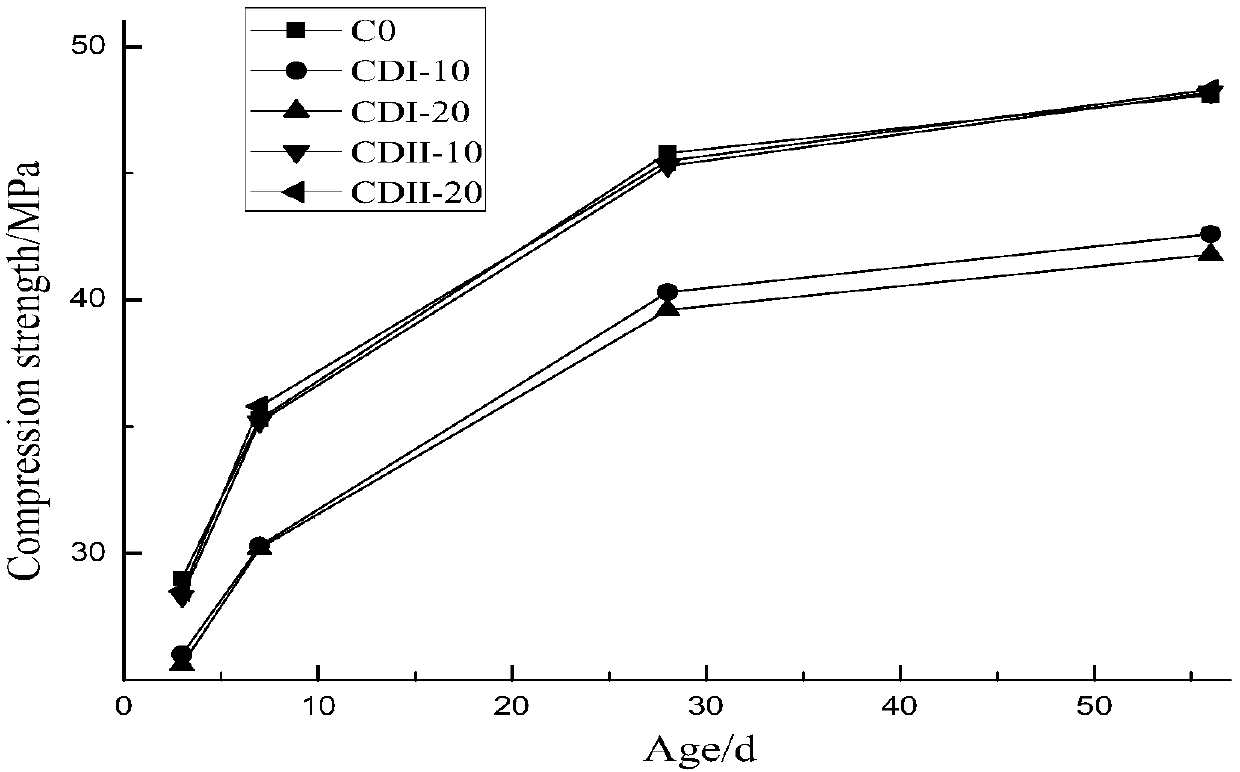

[0037] The modified dolomite powder-based mineral admixture DI and DII was used to prepare concrete, the mix ratio is shown in Table 1, and the performance of the concrete is shown in Table 2, Table 3, figure 1 with figure 2 shown

[0038] The raw materials for preparing concrete are: 42.5 ordinary Portland cement is used for cement, river sand with a fineness modulus of 2.6 is used for the admixture as described above, and river sand with a fineness modulus of 2.6 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com