Method for preparing vinylene carbonate through micro channel reaction

A vinylene carbonate, microchannel reaction technology, applied in electrochemical generators, electrical components, circuits, etc., can solve the problems of complicated preparation process, low crude product yield, and many by-products, etc., to improve reaction efficiency. , high yield, complete reaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

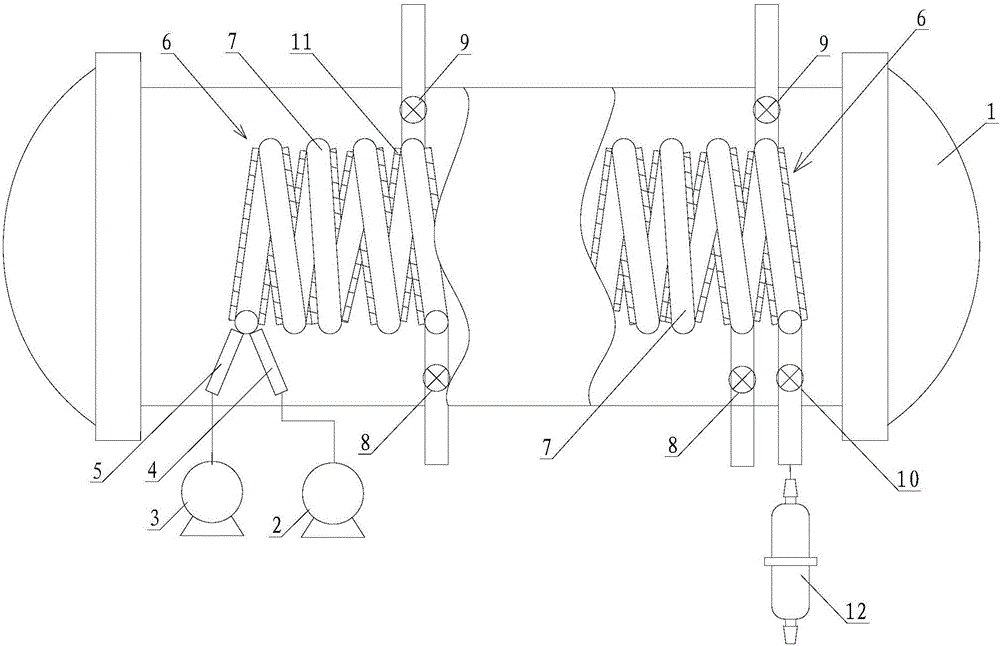

[0028] (1) The equipment that described method uses comprises enhanced mass transfer type microchannel reactor 1, metering pump one 2, metering pump two 3, microfilter 12, and enhanced mass transfer type microchannel reactor comprises preheater one 4, Preheater 2 5, ultrasonic device 11, and microchannel modules 6 made of ceramics connected in sequence, each microchannel module 6 includes a spiral tubular microchannel 7 with a heart-shaped internal structure and a hydraulic diameter of 0.5mm , an exhaust valve 8, a nitrogen replacement valve 9, an ultrasonic device 11 is arranged on the outer wall of the spiral tubular microchannel 7, and one of the microchannel modules located on the outermost side is also provided with a discharge valve 10;

[0029] (2) Mix chloroethylene carbonate and dimethyl carbonate evenly to obtain a mixed solution, input the mixed solution through the metering pump 12 into the preheater 14 to preheat to 25°C, and input the triethylamine through the met...

Embodiment 2

[0031] (1) The equipment that described method uses comprises enhanced mass transfer type microchannel reactor 1, metering pump one 2, metering pump two 3, microfilter 12, and enhanced mass transfer type microchannel reactor comprises preheater one 4, Preheater 2 5, ultrasonic device 11, and microchannel modules 6 made of polytetrafluoroethylene connected in sequence, each microchannel module 6 includes a spiral tubular inner structure with a heart-shaped structure and a hydraulic diameter of 0.5 mm. Microchannel 7, exhaust valve 8, nitrogen replacement valve 9, ultrasonic device 11 are arranged on the outer wall of spiral tubular microchannel 7, and one of the microchannel modules located at the outermost side is also provided with discharge valve 10;

[0032] (2) Mix chloroethylene carbonate and diethyl carbonate evenly to obtain a mixed solution, input the mixed solution through the metering pump 12 into the preheater 14 to preheat to 35°C, and input the triethylamine throug...

Embodiment 3

[0034](1) The equipment that described method uses comprises enhanced mass transfer type microchannel reactor 1, metering pump one 2, metering pump two 3, microfilter 12, and enhanced mass transfer type microchannel reactor comprises preheater one 4, Preheater 2 5, ultrasonic device 11, and microchannel modules 6 made of polytetrafluoroethylene connected in sequence, each microchannel module 6 includes a spiral tubular inner structure with a heart-shaped structure and a hydraulic diameter of 0.5 mm. Microchannel 7, exhaust valve 8, nitrogen replacement valve 9, ultrasonic device 11 are arranged on the outer wall of spiral tubular microchannel 7, and one of the microchannel modules located at the outermost side is also provided with discharge valve 10;

[0035] (2) Mix chloroethylene carbonate and ethylene carbonate evenly to obtain a mixed solution, feed the mixed solution to preheater 14 through metering pump 12 to preheat to 30°C, and input triethylamine to The preheater 2 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com