Method for efficiently co-producing maltodextrin and rice protein by rice processing by-products

A maltodextrin and by-product technology, which is applied in the field of food finishing technology and sugar making, can solve the problems of only 10% utilization rate and waste, and achieve the effects of enhanced surface activity, improved extraction rate and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

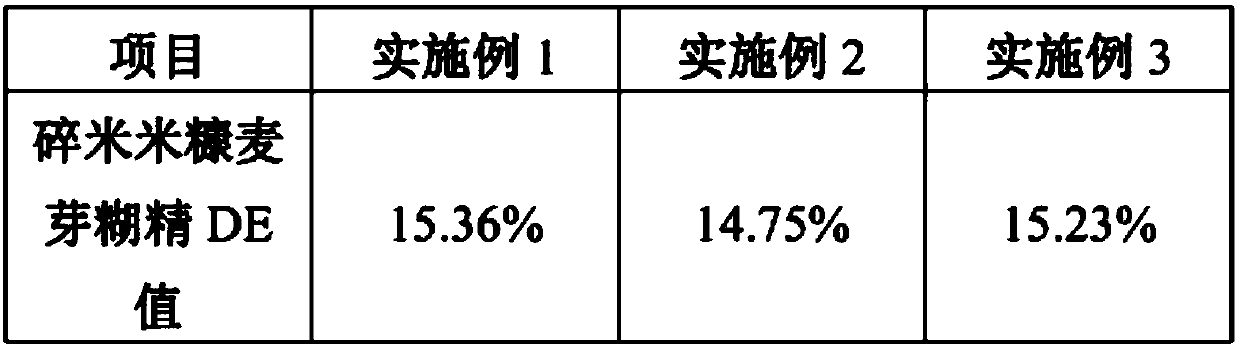

Embodiment 1

[0026] Get rice processing by-product mixture (broken rice 1000g, rice bran 1000g) as processing raw material, specifically comprise the following steps:

[0027] (1) Mechanical crushing: After removing impurities from the raw materials, use a grinder to crush broken rice and rice bran into powder, pass through a 70-mesh sieve, first pour it into a ball mill for low-speed grinding for 15 minutes, and the ball mill speed is 70rpm, then pour it into a cyclone mill and grind for 30 minutes , to get broken rice bran powder;

[0028] (2) Ultrasonic treatment: The broken rice bran powder obtained in step (1) is mixed with water at a ratio of 1:7 to liquid, and treated with ultrasonic waves for 15 minutes, ultrasonic intensity 2.4w / (g.cm2), and treatment temperature 38 ℃;

[0029] (3) Slight bioactivation: Sterilize the ultrasonic solution obtained in step (2) at 100°C, then add 1.5% of dry matter weight Bacillus subtilis ATCC 6633 and 0.2FPU / g of cellulose complex enzyme, and heat ...

Embodiment 2

[0036] Get rice processing by-product mixture (broken rice 1000g, rice bran 1000g) as processing raw material, specifically comprise the following steps:

[0037] (1) Mechanical crushing: After removing impurities from the raw materials, use a grinder to crush broken rice and rice bran into powder, pass through a 70-mesh sieve, first pour it into a ball mill for low-speed grinding for 20 minutes, and the ball mill speed is 80rpm, then pour it into a cyclone mill and grind for 25 minutes , to get broken rice bran powder;

[0038] (2) Ultrasonic treatment: the broken rice bran powder obtained in step (1) is mixed with water at a ratio of 1:7.5 to liquid, and treated with ultrasonic waves for 12 minutes, ultrasonic intensity 2.3w / (g.cm2), and treatment temperature 37 ℃;

[0039] (3) Slight bioactivation: Sterilize the ultrasonic solution obtained in step (2) at 100°C, then add 1.5% of dry matter weight Bacillus subtilis ATCC 6633 and 0.2FPU / g of cellulose complex enzyme, and hea...

Embodiment 3

[0046] Get rice processing by-product mixture (broken rice 1000g, rice bran 1000g) as processing raw material, specifically comprise the following steps:

[0047] (1) Mechanical crushing: After removing impurities from the raw materials, use a grinder to crush broken rice and rice bran into powder, pass through a 70-mesh sieve, first pour it into a ball mill for low-speed grinding for 25 minutes, and the ball mill speed is 90rpm, then pour it into a cyclone mill and grind for 20 minutes , to get broken rice bran powder;

[0048] (2) Ultrasonic treatment: the broken rice bran powder obtained in step (1) is mixed with water at a ratio of 1:8 to liquid, and treated with ultrasonic waves for 10 minutes, ultrasonic intensity 2.4w / (g.cm2), and treatment temperature 35 ℃;

[0049] (3) Slight bioactivation: Sterilize the ultrasonic solution obtained in step (2) at 100°C, then add 1.5% of dry matter weight Bacillus subtilis ATCC 6633 and 0.2FPU / g of cellulose complex enzyme, and heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com