Early-strength polycarboxylate water reducer and preparation method thereof

A technology of polycarboxylic acid and water-reducing agent, applied in the field of concrete admixtures, can solve the problems of sensitive dosage, negative impact on concrete durability, and will not improve early strength, etc. effect of reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

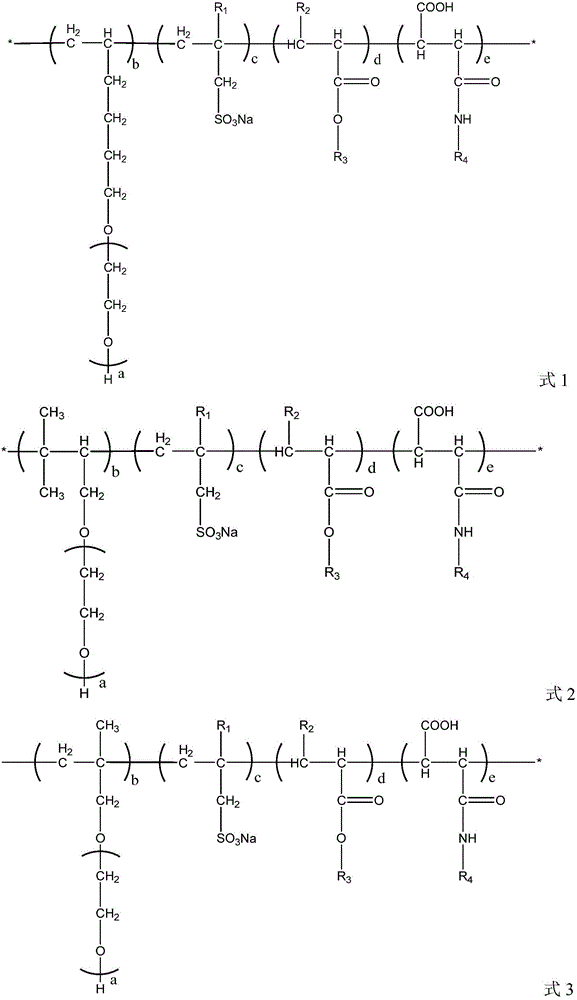

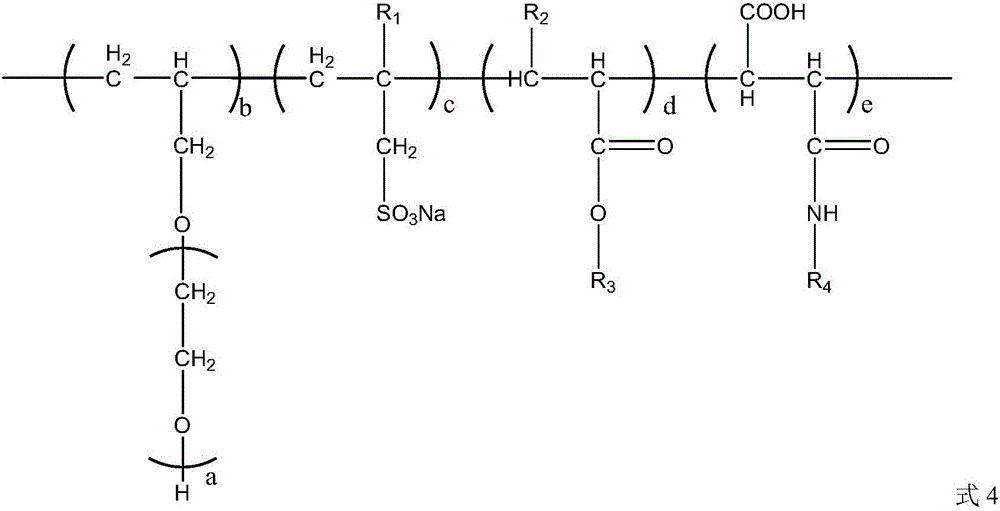

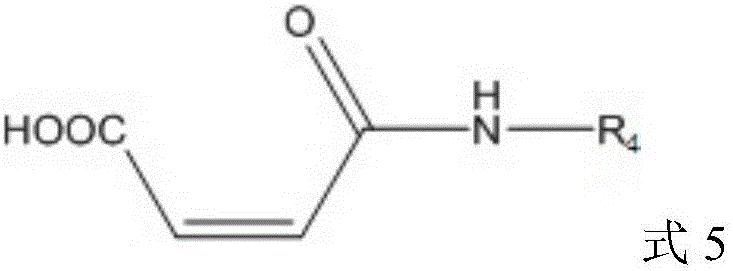

Method used

Image

Examples

Embodiment 1

[0036] An early-strength polycarboxylate superplasticizer whose molecular structure is shown in Formula 7, wherein a is 53-55, b is 14-16, d is 94-96, e is 21-23, and c is 2-2. 4, a, b, c, d are all integers; R 1 for CH 3 , R 2 for H, R 3 for H, R 4 For n-hexyl. GPC test average molecular weight is about 45000.

[0037]

[0038]The preparation method of the above-mentioned early-strength polycarboxylate water reducer, the specific steps are:

[0039] (1) The preparation method of maleic acid monoamide is: under an inert atmosphere, n-hexylamine and maleic anhydride are dropped into the reactor, then add solvent DMF and catalyzer benzenesulfonic acid, the quality of n-hexylamine and maleic anhydride total amount The concentration was 40wt%. During the stirring process, the temperature was slowly raised to 40° C., stirred and refluxed for 2 hours, and the solvent DMF was distilled off under reduced pressure to obtain maleic acid monoamide (N-n-hexyl maleic acid monoamid...

Embodiment 2

[0047] The early-strength polycarboxylate superplasticizer of the present invention has a molecular structural formula as shown in Formula 10, wherein a is 73-76, b is 11-13, d is 123-125, e is 45-47, and c is 0, a, b, d are all integers; R 2 for H, R 3 for H, R 4 For cyclohexyl. GPC test average molecular weight is about 60000.

[0048]

[0049] The preparation method of the above-mentioned early-strength polycarboxylate water reducer, the specific steps are:

[0050] (1) The preparation method of maleic acid monoamide is: under an inert atmosphere, cyclohexylamine and maleic anhydride are dropped into the reaction kettle, then add solvent DMF and catalyst p-toluenesulfonic acid, cyclohexylamine and maleic anhydride The mass concentration of the total amount of acid anhydride was 50wt%. During the stirring process, the temperature was slowly raised to 25° C., stirred and refluxed for 3.5 hours, and the solvent DMF was distilled off under reduced pressure to obtain male...

Embodiment 3

[0057] The early-strength polycarboxylate superplasticizer of the present invention has a molecular structural formula as shown in Formula 13, wherein a is 110-112, b is 12-14, d is 50-52, e is 89-91, and c is 0, a, b, d are all integers; R 2 for CH 3 , R 3 for H, R 4 For phenyl. GPC test average molecular weight is about 86000.

[0058]

[0059] The preparation method of the above-mentioned early-strength polycarboxylate water reducer, the specific steps are:

[0060] (1) The preparation method of maleic acid monoamide is: under inert atmosphere, aniline and maleic anhydride are dropped into reactor, then add solvent toluene and catalyst DMAP, the mass concentration of aniline and maleic anhydride total amount is 60wt% , during the stirring process, the temperature was slowly raised to 60° C., stirred and refluxed for 5 h, and the solvent toluene was distilled off under reduced pressure to obtain maleic acid monoamide (N-phenyl maleic acid monoamide). Wherein, the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com