Epoxy resin-carbon nanotube composite material and preparation method thereof

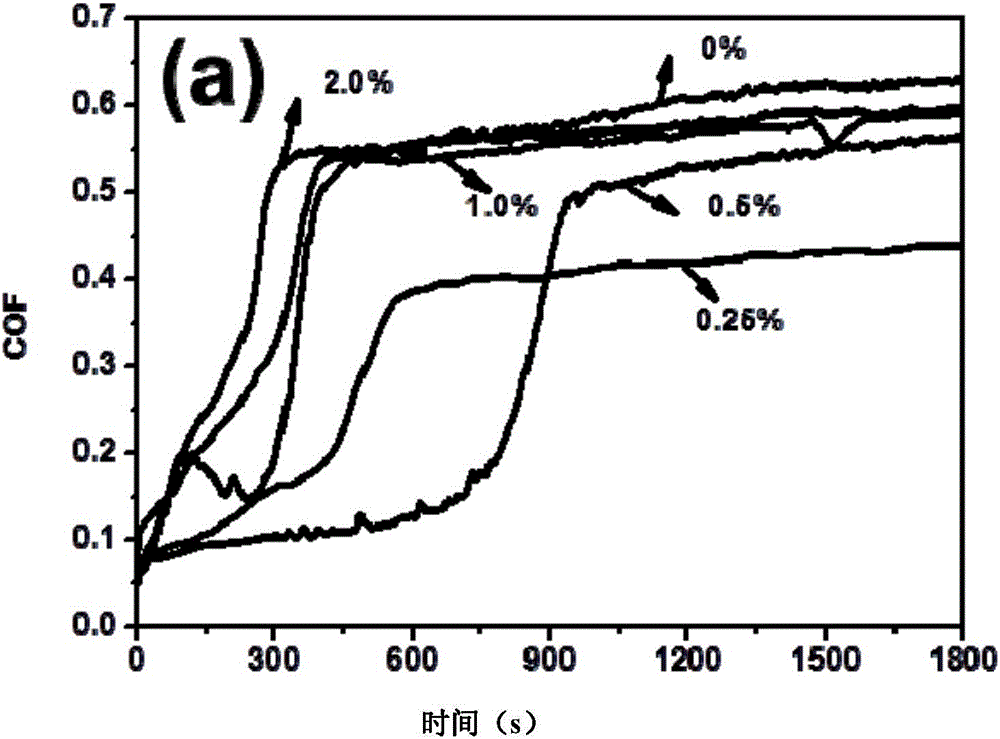

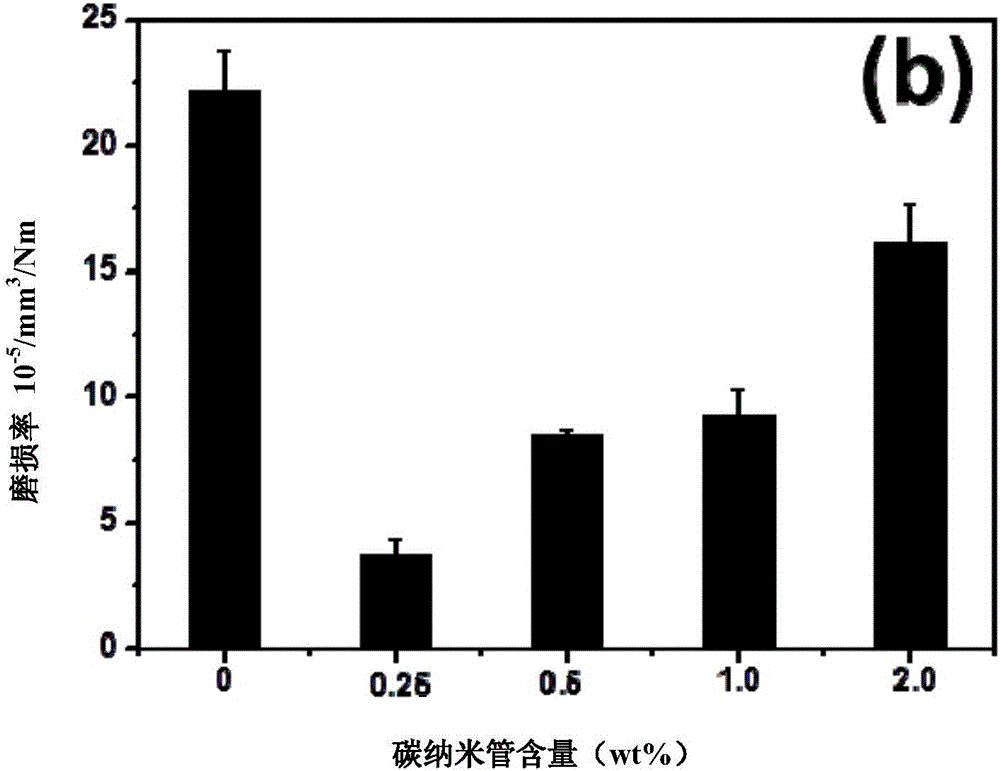

A technology of carbon nanotubes and epoxy resin, which is applied in the field of epoxy resin carbon nanotube composite materials and its preparation, can solve the problems that it is difficult to uniformly disperse carbon nanotubes, and it is difficult to effectively improve the performance of epoxy resin, so as to achieve scale The effect of chemical implementation, low friction coefficient and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

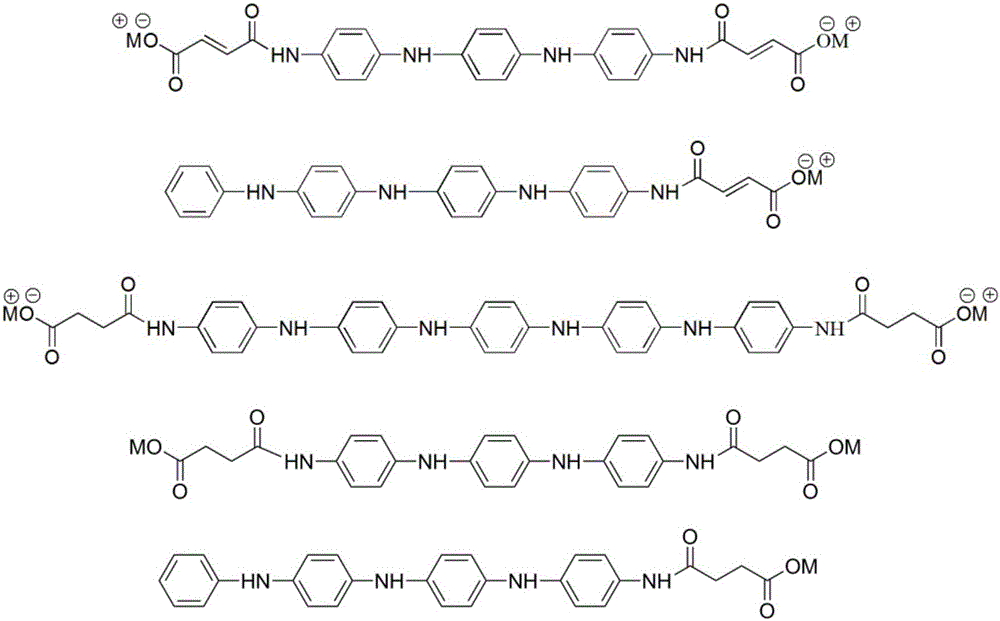

[0029] The preparation method of a kind of epoxy resin carbon nanotube composite material provided by the embodiment of the present invention comprises:

[0030] mixing carbon nanotubes with aniline oligomers and / or aniline oligomer derivatives in a solvent to obtain a dispersion of carbon nanotubes,

[0031] uniformly mixing the dispersion of carbon nanotubes and epoxy resin to form a mixture, and then removing the solvent in the mixture to obtain an epoxy resin carbon nanotube composite;

[0032] And, uniformly mix the epoxy resin carbon nanotube compound and the epoxy curing agent.

[0033] In some embodiments, the preparation method includes: mixing carbon nanotubes with aniline oligomers and / or aniline oligomer derivatives in a solvent, and performing ultrasonic treatment to obtain a dispersion of carbon nanotubes.

[0034] In some embodiments, the preparation method may also include: stirring, ultrasonic, vibration and other physical means (such as mechanical stirring, ...

Embodiment 1

[0065] Embodiment 1 This embodiment relates to a preparation process of a 0.25wt% epoxy resin carbon nanotube composite material (the carbon nanotube content in the composite material is 0.25wt%), including:

[0066] Add p-phenylenediamine sulfate (8.87g) and aniline (5.56g) into a three-necked flask of 1M hydrochloric acid solution (500mL), and cool to -5°C. Then 150mL of ammonium persulfate (13.62g) hydrochloric acid (1M) solution was slowly added dropwise to the above reaction flask through the dropping funnel. Washed with deionized water to obtain a dark green solid product. Then the product was washed with 10% ammonia solution, and then washed twice with deionized water, and finally the product (aniline trimer) was dried in a vacuum oven at 40° C. for use.

[0067] Weigh aniline trimer (50mg), carbon nanotubes (100mg) and tetrahydrofuran (20mL), sonicate for one hour, add epoxy resin E44 (32g) to the above mixed solution, remove tetrahydrofuran by distillation under redu...

Embodiment 2

[0068] Embodiment 2 This embodiment relates to a preparation process of a 0.5wt% epoxy resin carbon nanotube composite material (the carbon nanotube content in the composite material is 0.5wt%), including:

[0069] Weigh aniline trimer (100mg), carbon nanotubes (200mg) and tetrahydrofuran (40mL), sonicate for one hour, add epoxy resin E44 (32g) to the above mixed solution, remove tetrahydrofuran by distillation under reduced pressure, and then add Epoxy curing agent polyetheramine D230 (8.0g), stir evenly, debubble in a vacuum oven at 50°C for 15 minutes, introduce the mixture into a preheated tetrafluoroethylene mold, put it in the oven for curing, and the curing conditions at 80° C. for 6 hours to finally obtain a 0.5 wt % epoxy resin carbon nanotube composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com