Intelligent lubricating particle releasing wear-resisting material and preparation method thereof

A kind of wear-resistant material and intelligent technology, applied in the field of wear-resistant materials, can solve the problems of intelligent release of wear-resistant additives, inconsistent performance of materials inside and outside, and decline of wear-resistant performance, so as to achieve green and pollution-free preparation process, avoid The effect of unstable material properties and low wear rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

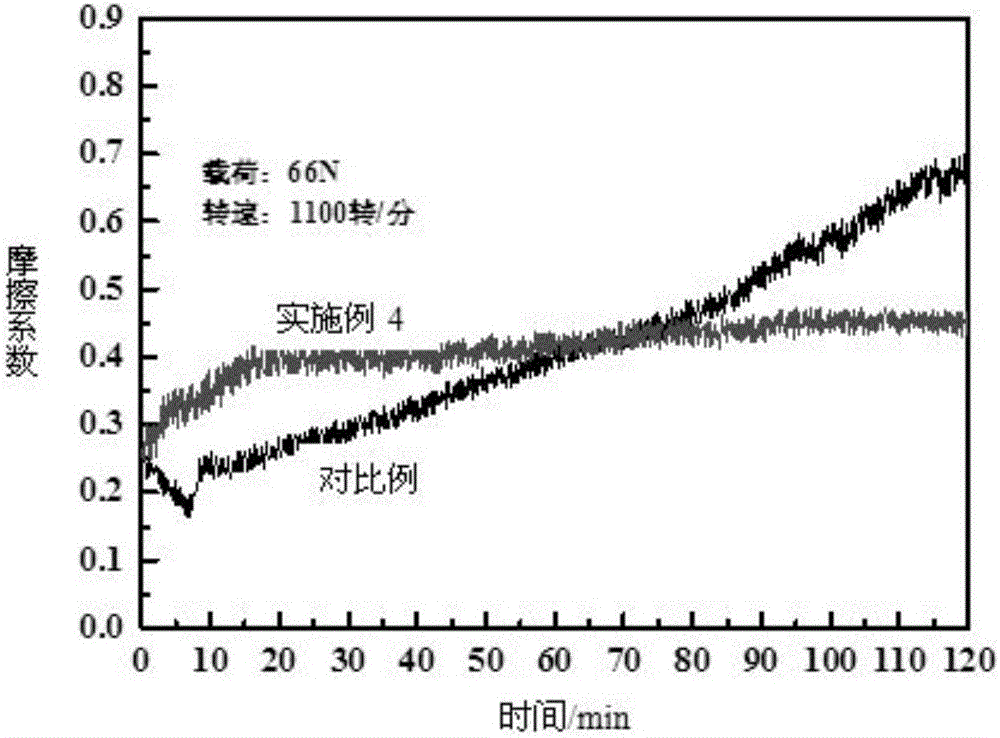

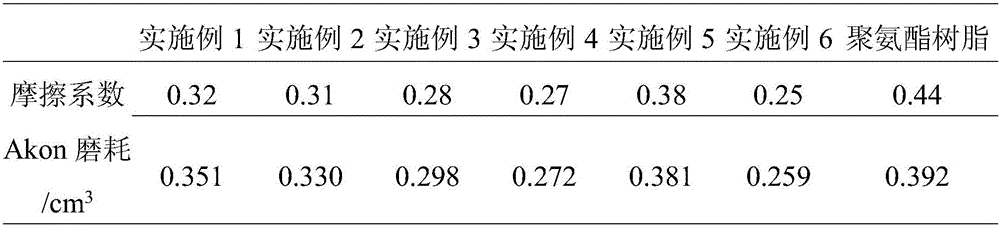

Examples

preparation example Construction

[0035] A method for preparing lubricating particle intelligent release wear-resistant material, the steps are as follows:

[0036] Step 1, the preparation of oil phase solution:

[0037] Mix the core material and polyisocyanate, (melting temperature of the core material + 5°C) ≤ mixing temperature ≤ (melting temperature of the core material + 10°C), and stir rapidly to obtain a uniformly mixed oil phase solution;

[0038] In step 1, the capsule core material is one of solid paraffin and liquid paraffin or a mixture of two in any proportion; the polyisocyanate is not particularly limited, and the polyisocyanate can be diisocyanate, triisocyanate, dimer of diisocyanate, One or more of the trimer of diisocyanate, dimer of triisocyanate, trimer of triisocyanate, dimer of diisocyanate and triisocyanate, trimer of diisocyanate and triisocyanate in any proportion Mixing, preferably toluene diisocyanate (TDI), diphenylmethane diisocyanate (IPDI), diphenylmethane diisocyanate (MDI) or...

Embodiment 1

[0059] Lubricating particles intelligently release wear-resistant materials, which are composed of 10wt% polyurethane microcapsules and 90wt% polyurethane resin.

[0060] The preparation method of the above-mentioned lubricating particle intelligent release wear-resistant material:

[0061] Step 1. Weigh the solid paraffin and TDI according to the mass ratio of 1:5, mix them at 70° C., and stir them rapidly to obtain a uniformly mixed oil phase;

[0062] Step 2, take sodium dodecylbenzenesulfonate and deionized water according to the mass ratio of 2:98, and mix them uniformly to obtain a medium solution;

[0063] Step 3: Weigh PEG600 and deionized water according to the mass ratio of 1:4, and prepare a reaction monomer solution with a concentration of 20%;

[0064] Step 4. Mix the oil phase and the medium solution at a mass ratio of 1:4, and emulsify on a high-speed shear emulsifier for 90 minutes at a speed of 5000 rpm to obtain an O / W solution;

[0065] Step 5. Gradually a...

Embodiment 2

[0068] Lubricating particles intelligently release wear-resistant materials, which are composed of 16wt% polyurethane microcapsules and 84wt% polyurethane resin.

[0069] The preparation method of the above-mentioned lubricating particle intelligent release wear-resistant material:

[0070] Step 1. Weigh the solid paraffin and TDI according to the mass ratio of 1:5, mix them at 70° C., and stir them rapidly to obtain a uniformly mixed oil phase;

[0071] Step 2, take sodium dodecylbenzenesulfonate and deionized water according to the mass ratio of 2:98, and mix them uniformly to obtain a medium solution;

[0072] Step 3: Weigh PEG600 and deionized water according to the mass ratio of 1:4, and prepare a reaction monomer solution with a concentration of 20%;

[0073] Step 4: Mix the oil phase and the medium solution at a mass ratio of 1:4, and emulsify on a high-speed shear emulsifier at a speed of 5000 rpm for 90 minutes;

[0074] Step 5. Gradually add the reaction monomer so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com