Edible fish skin collagen active composite membrane and preparation method thereof

A fish skin collagen and collagen technology, which is applied in the application field of bioactive packaging films, can solve the problems of poor antioxidant and antibacterial properties, few edible packaging films, and wide applications, and achieves good antioxidant activity. , The effect of preventing external microorganisms from contacting with food and prolonging the fresh-keeping period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

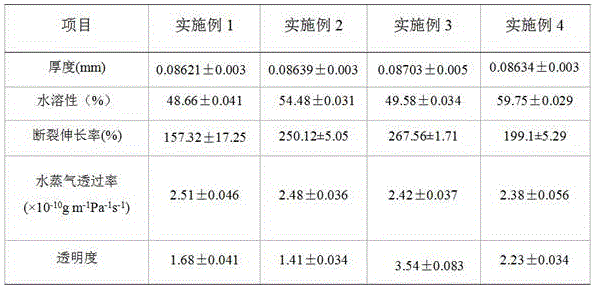

Embodiment 1

[0017] (1) Preparation of curcumin emulsifier: Weigh 0.5mg curcumin and 10mg beta-cyclodextrin into a 25ml dry small beaker, shake it back and forth to make it mechanically mix, then add 10ml water, and magnetically stir for 4h , to fully dissolve the cyclodextrin and fully wet the curcumin, then add 0.1g Tween-80 and continue stirring for 24 hours to obtain the curcumin emulsifier.

[0018] (2) Preparation of collagen solution: add 10 ml of curcumin emulsifier to 0.4 g of fish skin collagen, and dissolve with magnetic stirring at 45°C to make collagen solution;

[0019] (3) Preparation of edible fish skin collagen active composite membrane: Add 0.1 g of glycerin as a plasticizer to the collagen solution obtained in step (2), stir evenly, let it stand for degassing, and cast a composite membrane membrane Spread the casting solution on a plexiglass frame of 120 mm × 80 mm × 4 mm to form a film. The film forming temperature is 23 ± 0.5 °C and the film forming time is 24 h to pre...

Embodiment 2

[0022] (1) Preparation of curcumin emulsifier: Weigh 1mg curcumin and 10mg beta-cyclodextrin into a 25ml dry small beaker, shake it back and forth to make it mechanically mix, then add 10ml water, and magnetically stir for 4h, Fully dissolve the cyclodextrin and fully wet the curcumin, then add 0.1g Tween 80 and continue stirring for 24 hours to obtain the curcumin emulsifier.

[0023] (2) Preparation of collagen solution: add 10 ml of curcumin emulsifier to 0.4 g of fish skin collagen, and dissolve with magnetic stirring at 45°C to make collagen solution;

[0024] (3) Preparation of edible fish skin collagen active composite membrane: Add 0.1 g of glycerin as a plasticizer to the collagen solution obtained in step (2), stir evenly, let it stand for degassing, and cast a composite membrane membrane Spread the casting solution on a plexiglass frame of 120 mm × 80 mm × 4 mm to form a film. The film forming temperature is 23 ± 0.5 °C and the film forming time is 36 h to prepare a...

Embodiment 3

[0027] (1) Preparation of curcumin emulsifier: Weigh 2.5mg curcumin and 10mg beta-cyclodextrin into a 25ml dry beaker, shake it back and forth to make it mechanically mix, then add 10ml water, and magnetically stir for 4h , to fully dissolve the cyclodextrin and fully wet the curcumin, then add 0.1g Tween 80 and continue stirring for 24 hours to obtain the curcumin emulsifier.

[0028] (2) Preparation of collagen solution: add 10 ml of curcumin emulsifier to 0.4 g of fish skin collagen, and dissolve with magnetic stirring at 45°C to make collagen solution;

[0029] (3) Preparation of edible fish skin collagen active composite membrane: Add 0.1 g of glycerin as a plasticizer to the collagen solution obtained in step (2), stir evenly, let it stand for degassing, and cast a composite membrane membrane Spread the casting solution on a plexiglass frame of 120 mm × 80 mm × 4 mm to form a film. The film forming temperature is 23 ± 0.5 °C and the film forming time is 40 hours to prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com