Waterborne anti-corrosive coating and preparation method thereof

A water-based technology for anti-corrosion coatings, applied in anti-corrosion coatings, coatings, etc., can solve the problems of low coating hardness, poor corrosion resistance, low porosity, etc., and achieve high matrix bonding force, good wear resistance, and good plasticity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

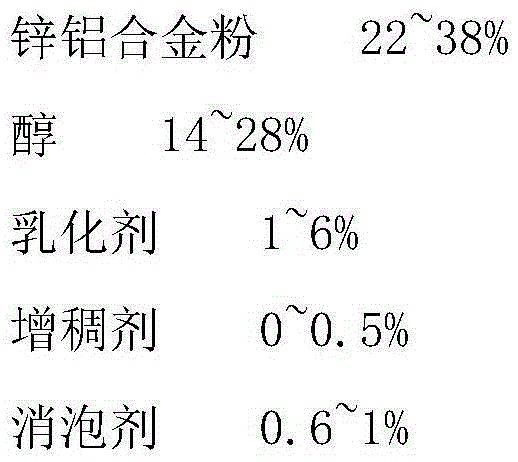

Embodiment 1

[0012] A water-based anti-corrosion coating and its preparation method: preparation of component A mixture: first add 30% zinc-aluminum alloy powder (comprising 25% zinc powder, 4.4% aluminum powder and 0.6% silver powder) to 8% alcohol solution and stir 5min, then add 6% emulsifier and stir for 5min, then add 0.6% defoamer and stir for 5min, then add 0.1% thickener and stir for 5min; prepare component B mixture: add 0.9% micronized calcium oxide Slowly added to 15% deionized water and stirred for 15 minutes, then added 15% silane coupling agent and stirred for 5 minutes. Slowly pour the mixed solution of component A into the mixed solution of component B and stir for 15 minutes; add the rest of deionized water and stir for 15 minutes to obtain a water-based anti-corrosion coating.

[0013] The water-based anti-corrosion coating prepared in this example, the obtained coating is tested: the coating thickness is 25 ± 10 μm, the hardness is 5H, the adhesion is 4 grades, the salt ...

Embodiment 2

[0015] A water-based anti-corrosion coating and its preparation method: prepare the A-component mixture: first add 25% zinc-aluminum alloy powder (comprising 21% zinc powder, 3.8% aluminum powder and 0.2% silver powder) to 12% alcohol solution and stir 5min, then add 5% emulsifier and stir for 5min, then add 0.7% defoamer and stir for 5min, then add 0.2% thickener and stir for 5min; prepare component B mixture: add 0.6% micronized calcium oxide Slowly added to 12% deionized water and stirred for 15 min, then added 15% silane coupling agent and stirred for 5 min. Slowly pour the mixed solution of component A into the mixed solution of component B and stir for 15 minutes; add the rest of deionized water and stir for 15 minutes to obtain a water-based anti-corrosion coating.

[0016] The water-based anti-corrosion coating prepared in this example, the obtained coating is tested: the coating thickness is 20 ± 6 μm, the hardness is 5H, the adhesion is 5 grades, the salt resistance ...

Embodiment 3

[0018] A water-based anti-corrosion coating and its preparation method: prepare the A-component mixture: first add 35% zinc-aluminum alloy powder (comprising 30% zinc powder, 4.2% aluminum powder and 0.8% silver powder) to 16% alcohol solution and stir 5min, then add 4% emulsifier and stir for 5min, then add 0.8% defoamer and stir for 5min, then add 0.2% thickener and stir for 5min; prepare component B mixture: add 0.8% micronized calcium oxide Slowly added to 15% deionized water and stirred for 15 minutes, then added 12% silane coupling agent and stirred for 5 minutes. Slowly pour the mixed solution of component A into the mixed solution of component B and stir for 15 minutes; add the rest of deionized water and stir for 15 minutes to obtain a water-based anti-corrosion coating.

[0019] The water-based anti-corrosion coating prepared in this example, the obtained coating is tested: the thickness of the coating is 21 ± 3 μm, the hardness is 6H, the adhesion is grade 5, the sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com