Preparation method of carbon-lead battery anode

A carbon-lead battery and negative electrode technology, which is applied in the field of carbon-lead battery negative electrode preparation, can solve the problems of accelerating the hydrogen evolution of the negative plate, difficult to mix uniformly, and the carbon materials cannot give full play to their advantages, and achieves the advantages of reducing floating carbon and prolonging the cycle life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

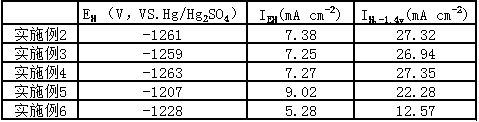

Examples

Embodiment 1

[0032] Pretreatment: Disperse 1 g of GO in 50 mL of 75% absolute ethanol and sonicate for 10 min, pour this mixture into 150 mL of 0.1 mol / L Pb(NO 3 ) 2 The solution was magnetically stirred for 3 hours; then 12.5 mL of ammonia solution with a concentration of 15 mol / L was added dropwise to the above solution, while ultrasonication was performed for 10 minutes, the above solution was filtered and vacuum-dried at 80°C for 12 hours to obtain samples.

[0033] Pyrolysis: The samples prepared above were further heated in N 2 Heat to 500°C at a rate of 10°C per minute in the air and keep it warm for 2 hours to obtain the pyrolysis product.

[0034] Pickling: Add 1.5g of pyrolysis product to 300ml of HCl solution with a concentration of 5mol / L, ultrasonically treat for 15min at 25°C, stir magnetically for 20min, let it rest for 40min, absorb the supernatant with a dropper, and repeat the above process 3 times; then the solution was filtered and washed with distilled water until Ph...

Embodiment 2

[0036] The preparation process of negative electrode paste is as follows: first, 0.2g acetylene black, 0.1g lignin, 0.5g polypropylene fiber, 0.4gBaSO 4 , 0.7g of humic acid and 1g of PbO / GO composite were ground evenly in an agate mortar, and then 97g of lead powder with an oxidation degree of 75% was added to the above mixture and mixed well; secondly, the H 2 Add O into the mortar and stir well, then add 1.25g / cm 3 H 2 SO 4, add it into the mortar evenly and slowly three times and keep stirring, and finally add an appropriate amount of water to adjust the apparent density of the lead paste to about 4.2g / cm 3 . Apply 1.0g of the above-prepared lead paste on an area of 1.5*0.5cm 2 On the negative electrode active material, the thickness is 1mm; then the plate after manual paste is placed in the H 2 SO 4 (1.25g / cm 3 ) solution for 1-3S. Put the prepared plate into a constant temperature and humidity box for curing treatment. The curing temperature is 55°C, the curing...

Embodiment 3

[0038] The preparation process of negative electrode paste is as follows: first, 0.2g acetylene black, 0.1g sodium lignosulfonate, 0.5g polyester fiber, 0.4gBaSO 4 , 0.7g of humic acid and 1g of PbO / GO composite were ground evenly in an agate mortar, and then 97g of lead powder with an oxidation degree of 75% was added to the above mixture and mixed well; secondly, the H 2 Add O into the mortar and stir well, then add 1.25g / cm 3 H 2 SO 4 , add it into the mortar evenly and slowly three times and keep stirring, and finally add an appropriate amount of water to adjust the apparent density of the lead paste to about 4.2g / cm 3 . Apply 1.0g of the above-prepared lead paste on an area of 1.5*0.5cm 2 On the negative electrode active material, the thickness is 1mm; then the plate after manual paste is placed in the H 2 SO 4 (1.25g / cm 3 ) solution for 1-3S. Put the prepared plate into a constant temperature and humidity box for curing treatment. The curing temperature is 45°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com