Waterproof, high-/low-temperature-resistant and low-VOC (Volatile Organic Compound) polyurethane coating capable of being cured quickly

A polyurethane coating, high and low temperature resistant technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of not having waterproof properties, not suitable for normal temperature curing operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0043] As an embodiment of the present invention, the preparation method of the polyether polyol can adopt the preparation method known to those skilled in the art, and the preparation of the polyether polyol is mainly prepared by the principle of cationic polymerization. In the present invention, the preferred initiator is a mixture of pentaerythritol and formula (1) in a weight ratio of 1:0.2, the comonomers are tetrahydrofuran and propylene oxide, and boron trifluoride ether complex is used as a catalyst. Concrete preparation process is as follows:

[0044] Mix monomer tetrahydrofuran, pentaerythritol and formula (1), under the catalyst boron trifluoride etherate complex, cool to -5°C in an ice-salt bath, slowly add propylene oxide under stirring, and carry out polymerization; the polymerized Polyether polyols are refined.

[0045] refined:

[0046] During the preparation of tetrahydrofuran-cyclic ether copolyether polyol by cationic ring-opening polymerization, due to th...

Embodiment approach 1

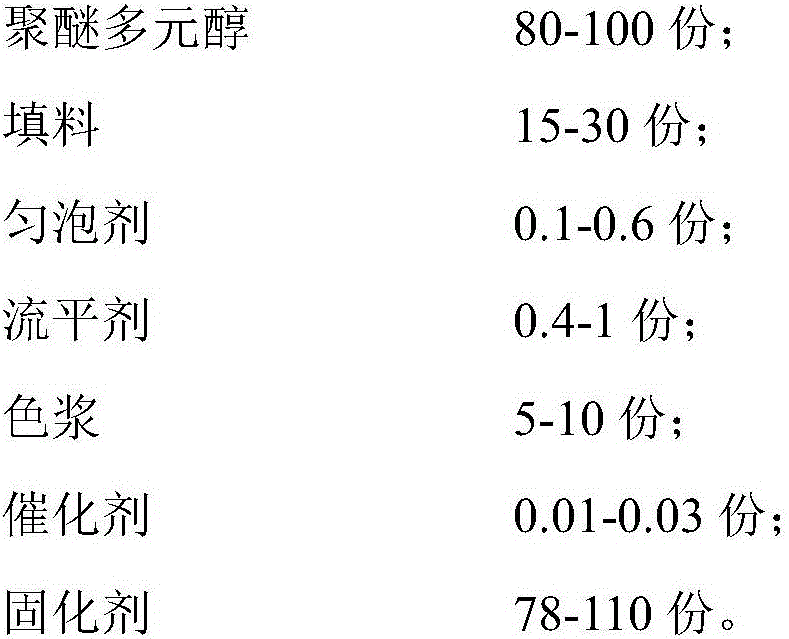

[0120] Embodiment 1: A rapidly curing, waterproof, high and low temperature resistant, low VOC polyurethane coating, in parts by weight, its preparation raw materials include:

[0121]

Embodiment approach 2

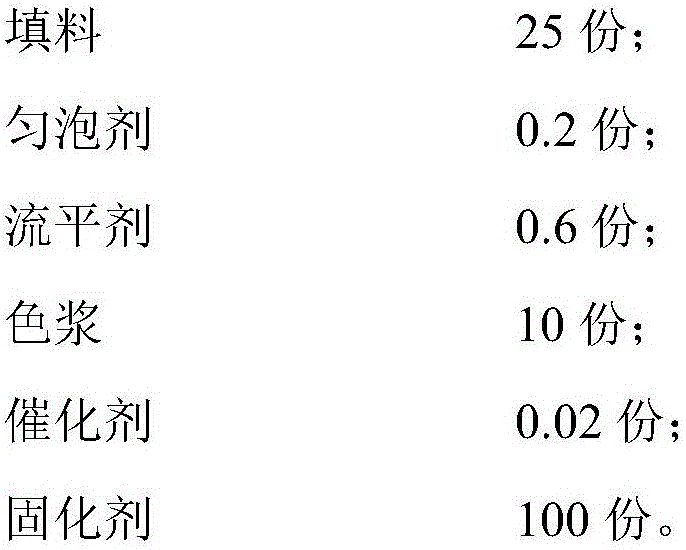

[0122] Embodiment 2: The rapidly curing, waterproof, high and low temperature resistant, low VOC polyurethane coating as described in Embodiment 1, in parts by weight, its preparation raw materials include:

[0123]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com