High-gloss, impact resistant and super weather-resistant carboxyl terminated fluorine-containing polyester resin for powder coating and preparation method thereof

A technology of fluorine-containing polyester and powder coatings, applied in powder coatings, polyester coatings, coatings, etc., can solve the problems of high price, low gloss, poor compatibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

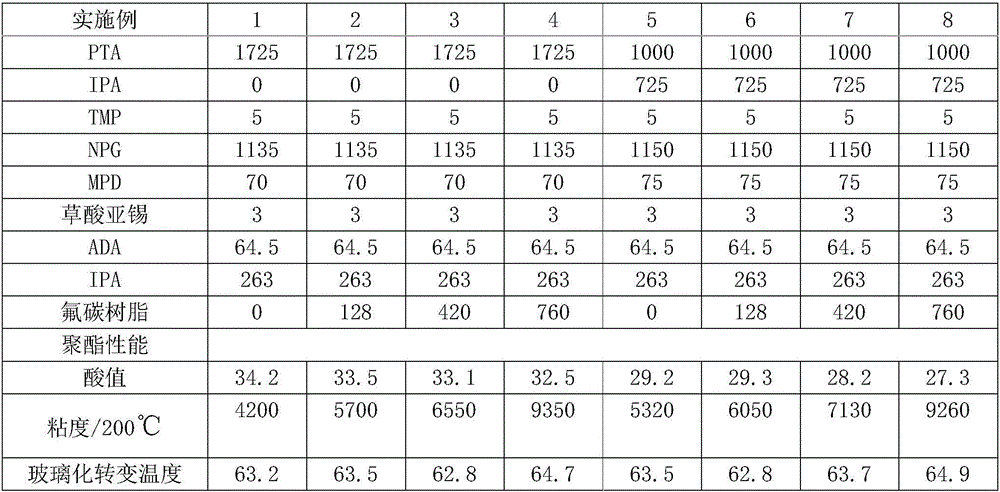

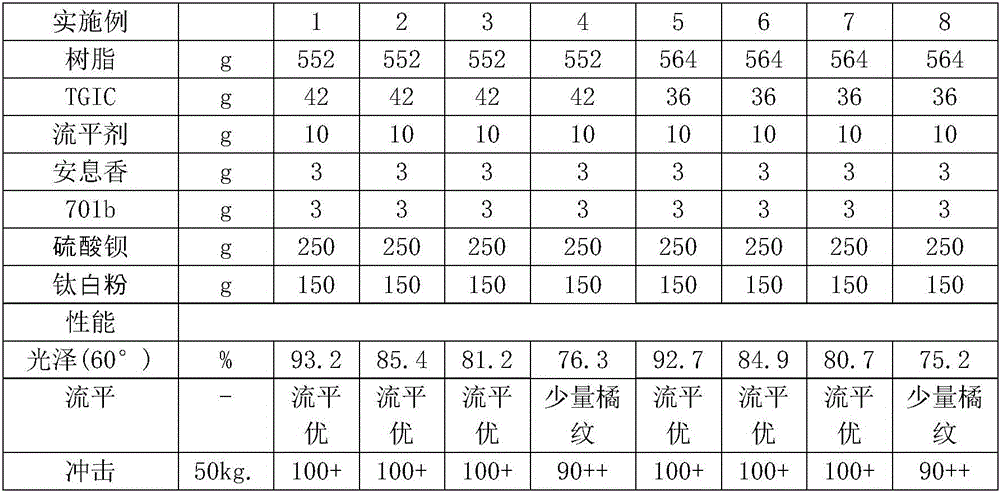

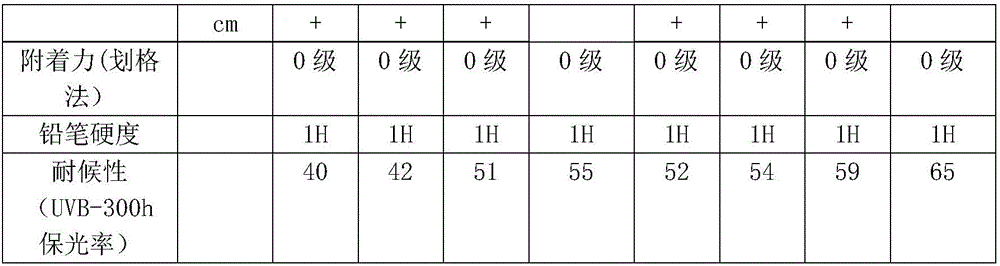

[0032] A high-gloss, impact-resistant and super-weather-resistant carboxyl-terminated fluorine-containing polyester resin for powder coatings, the formula is as follows in Table 1:

[0033] A method for preparing a carboxyl-terminated fluorine-containing polyester resin for powder coatings with high gloss, impact resistance and super weather resistance, comprising the following steps:

[0034] 1) In a 5-liter glass reactor, add polyols and branching agents in the ratio listed in Table 1, heat and melt at 100-140°C, then add the corresponding aromatic dibasic acid and catalyst in turn, and heat up with nitrogen gas. The system begins to undergo esterification reaction at 185-194°C and water is released, then raise the temperature of the system to 240°C at a heating rate of 5°C / h, and maintain at 240°C for 1-2h until the system is clear, and the acid value of the system reaches 7 -12mgKOH / g resin;

[0035] 2) Cool down to 235°C and add an acidolysis agent for 1-3h, so that the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com