Remote plasma atomic layer deposition system modulated by variable electric fields

A remote plasma and atomic layer deposition technology, applied in coating, metal material coating process, gaseous chemical plating, etc., can solve the problem of uncontrollable crystal orientation of thin films, and increase adsorption and chemical reaction active sites , Improve the effect of chemical reactivity and film coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

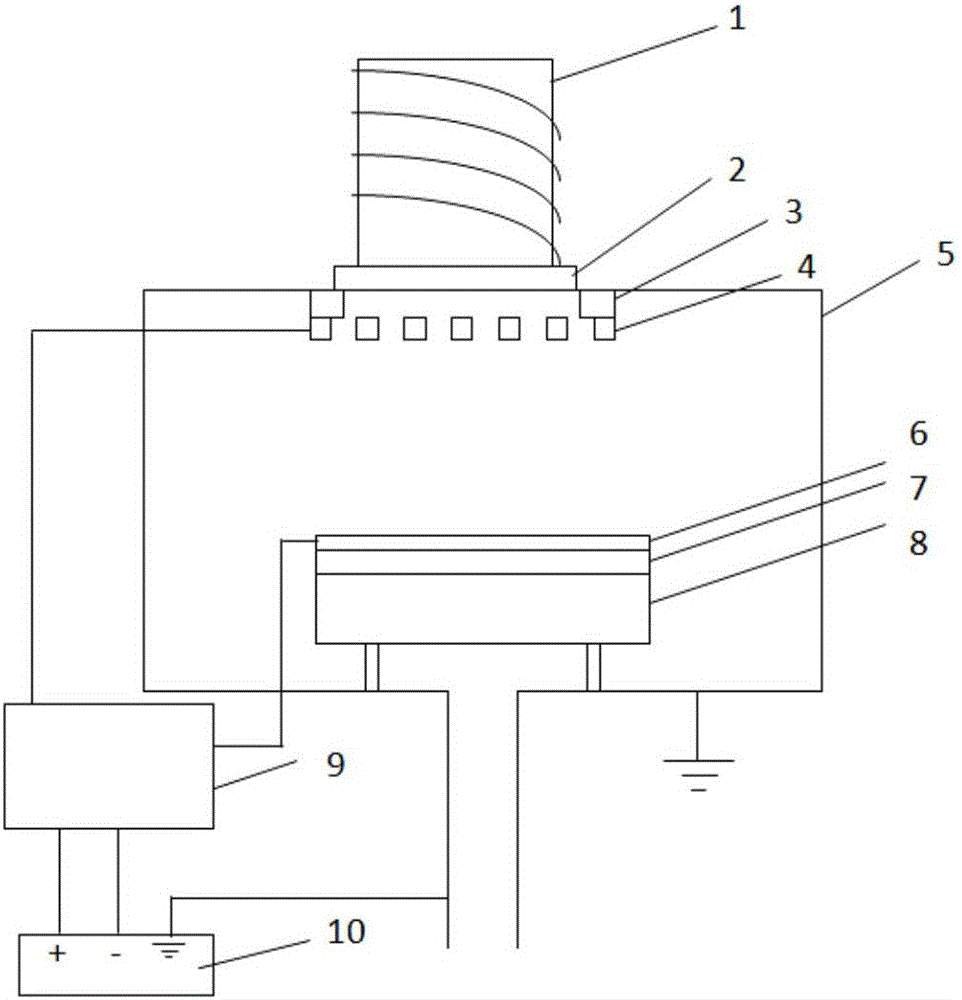

[0020] The embodiment of the present application provides a remote plasma atomic layer deposition system modulated by a variable electric field, which solves the problem that the film deposition rate in the prior art is much lower than the theoretical expectation, and the crystal orientation of the film obtained by atomic layer deposition is random and uncontrollable. The obtained thin film is mostly a problem of a polycrystalline thin film with many defects.

[0021] The technical solution of the embodiment of the present application is to solve the above-mentioned technical problems, and the general idea is as follows:

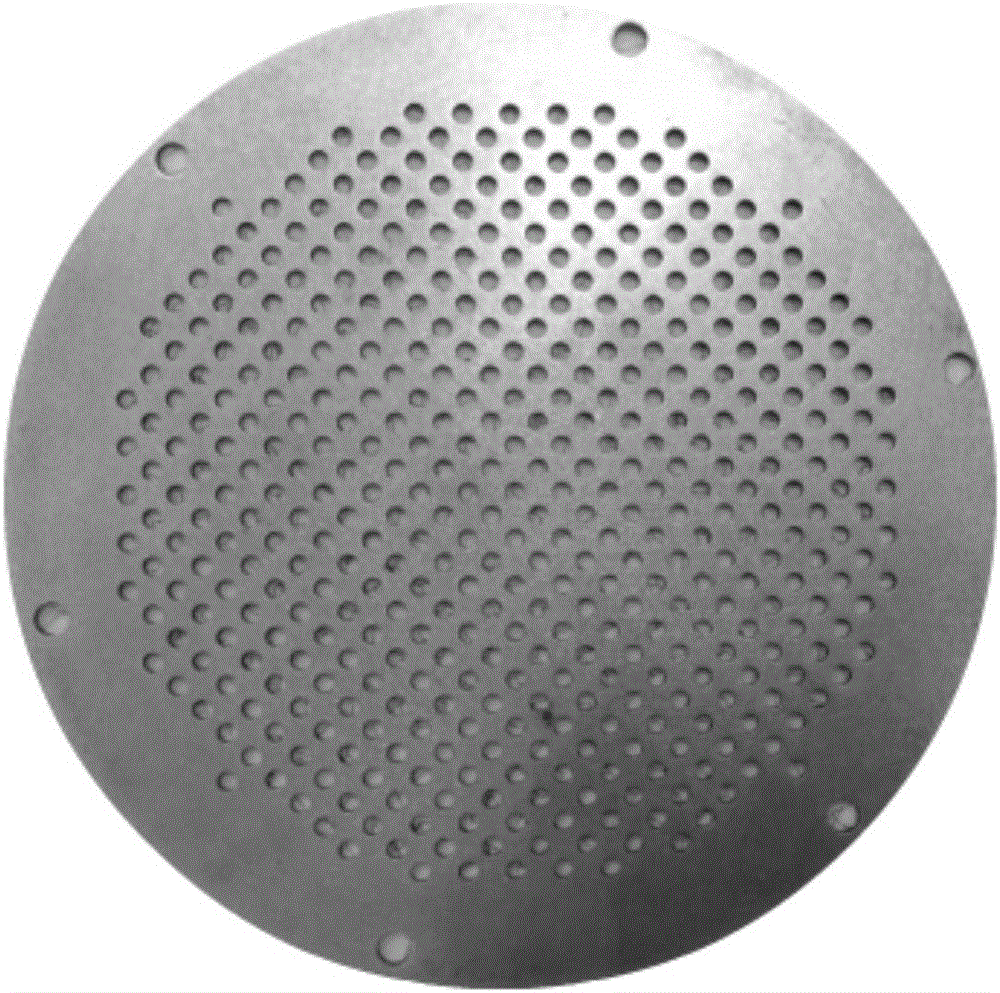

[0022] A remote plasma atomic layer deposition system with variable electric field modulation. A variable uniform electric field with arbitrarily set size and polarity is introduced into the reaction chamber. The dipole effect on the plasma reaction source and the electric field effect on the plasma reaction source can change the orientation distribution of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com