Electrothermic type stainless steel product automatic drying device

A drying device, stainless steel technology, applied in drying, dryer, drying gas layout and other directions, can solve the problems of left un-dried corners, take a long time, high risk factor, save drying time, design Ingeniously conceived to reduce the effect of dangerous accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

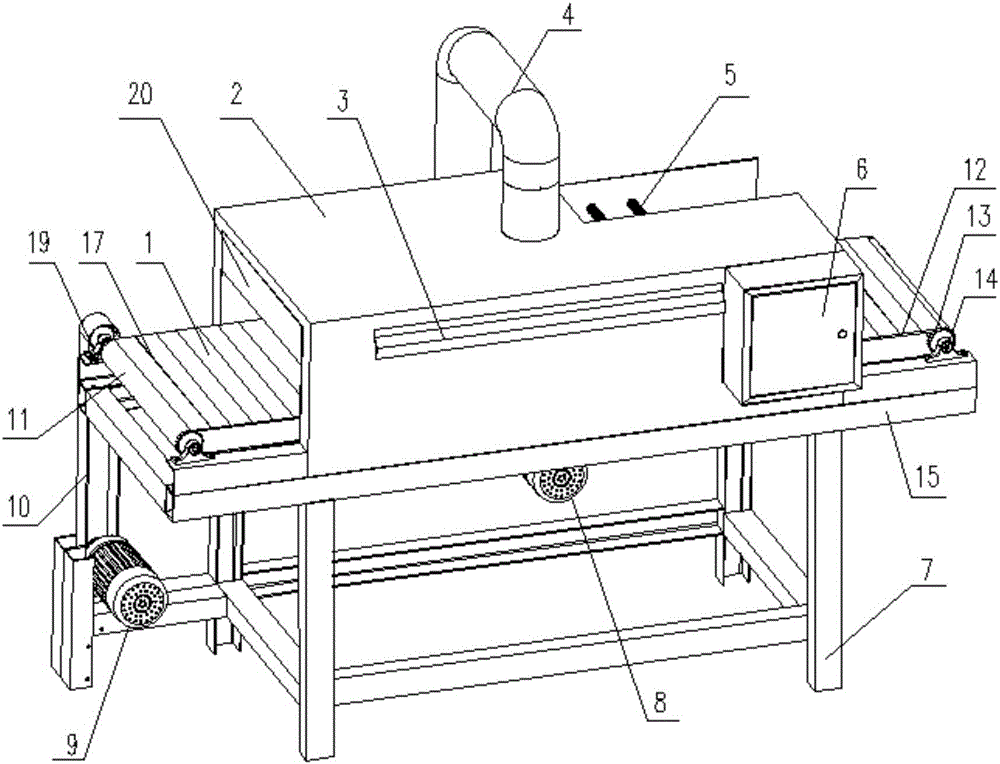

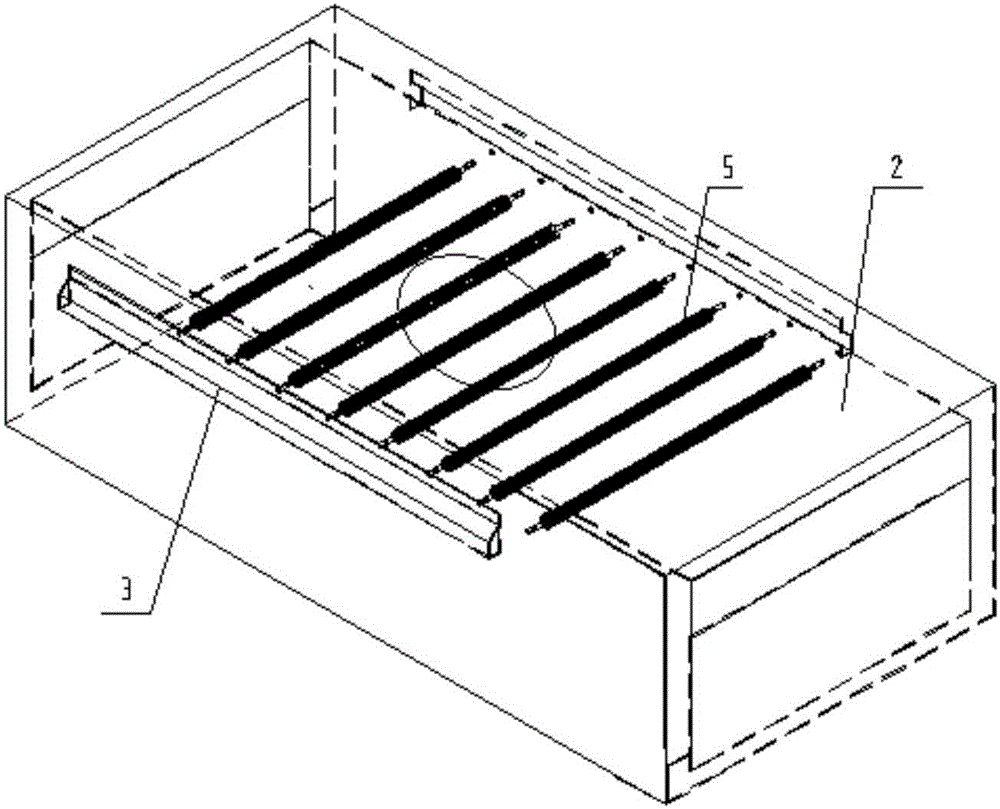

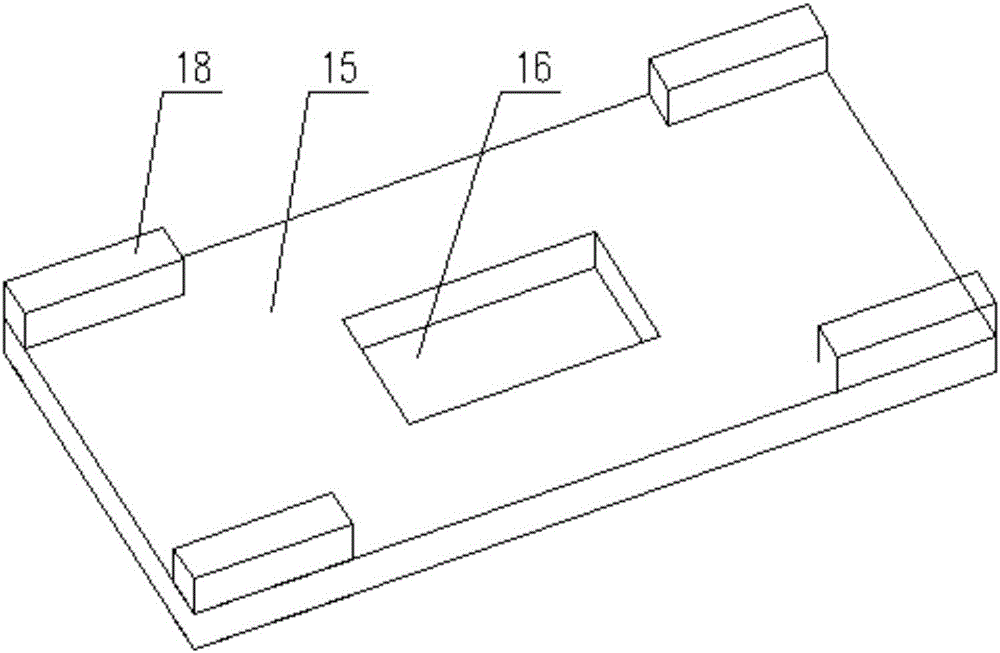

[0019] The main structure of the electrothermal automatic drying device for stainless steel products involved in this embodiment includes: conveyor belt 1, anti-radiation cover plate 2, heating pipe fixing frame 3, air guide pipe 4, heating pipe 5, power distribution control box 6, base 7 , blower motor 8, transmission motor 9, power transmission chain 10, drive shaft 11, conveyor belt chain 12, first sprocket 13, bearing 14, support plate 15, blast outlet 16, conveyor belt cross bar 17, bearing pad 18 and Second sprocket 19; Base 7 is the structure that extends the fifth support pin to the left at the left rear side support pin on the basis of the common four-leg support structure, and connects between the fifth support pin and the left rear side support pin A transmission motor 9 for providing power to the conveyor belt 1 is fixed on the cross bar, and a support plate 15 with a cuboid structure is fixed horizontally on the upper part of the base 7. The four corners of the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com