Solvent recovering system and method, coating machine and photoresist coating method

A recycling system and coating machine technology, applied in the direction of photoplate making process coating equipment, etc., can solve the problems of photoresist liquid deterioration, inability to regenerate, increase production cost, etc., and achieve the effect of saving the cost of solvent supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

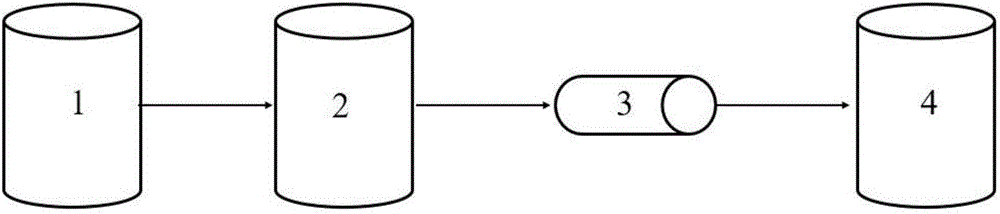

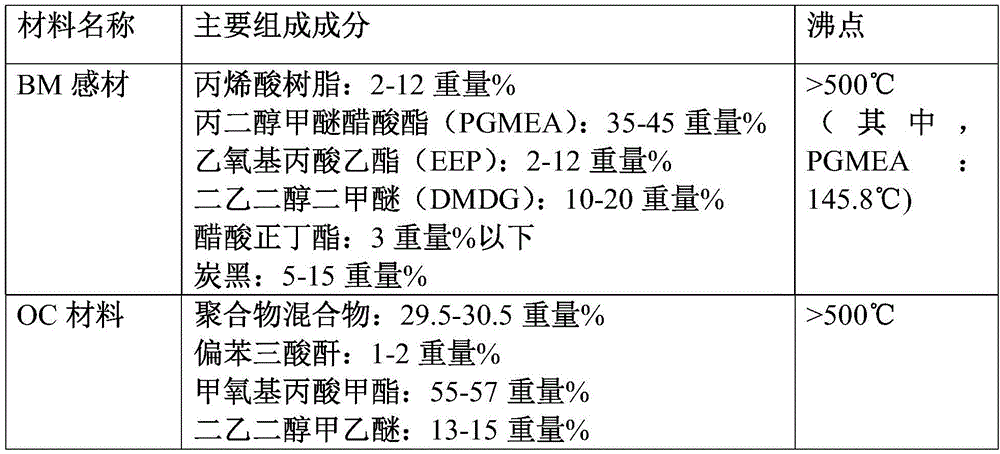

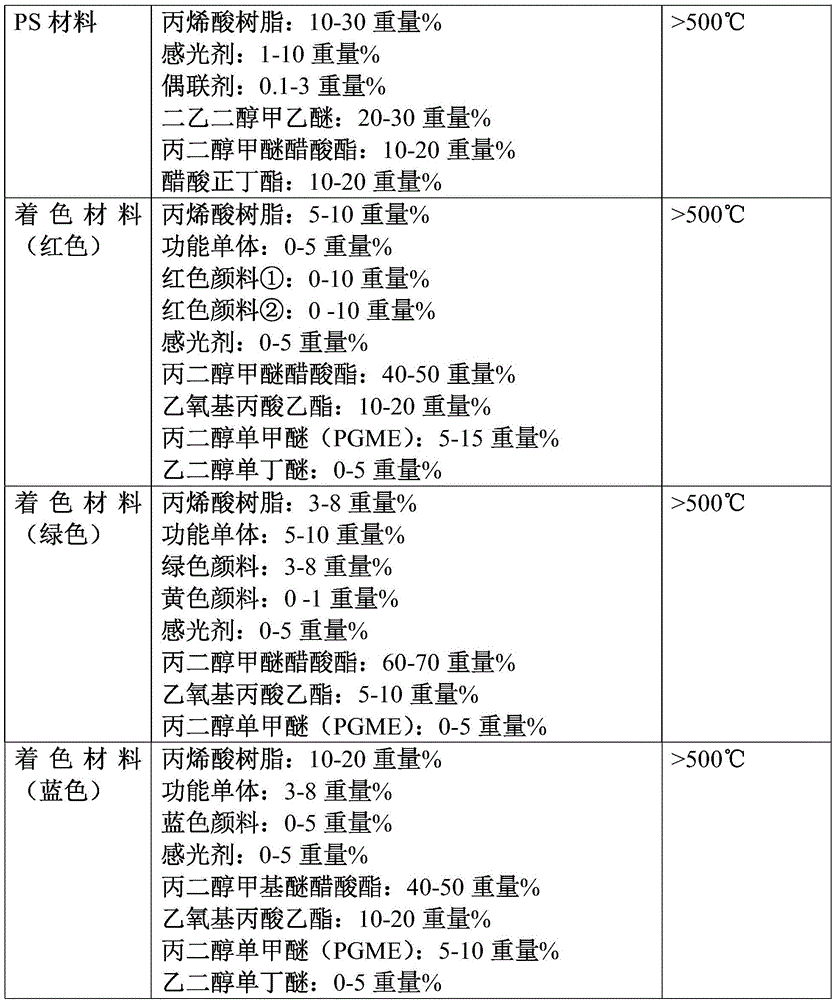

[0034] The present invention has no particular limitation on the specific structure of the distillation tank, as long as the solvent in the mixed waste liquid can be evaporated without evaporating the photoresist so as to separate the solvent from the photoresist. Since the photoresist and the solvent belong to two substances with different boiling points, the boiling point of the solvent is lower, while the boiling point of the photoresist is higher, and the separation of the two can be achieved by evaporating the solvent, and it can be made under low pressure and / or heating conditions. The solvent evaporates faster, which facilitates solvent recovery. Correspondingly, according to a preferred embodiment of the present invention, the distillation tank includes: a tank body of the distillation tank, which is used to contain the mixed waste liquid to be recovered; and a low-pressure pump, which is used to lower the distillation tank during the distillation process. the pressure...

Embodiment 1

[0062] This example is used to illustrate the solvent recovery system and method provided by the present invention.

[0063] In this embodiment, the mixed waste liquid to be recovered contains 20% by weight of photoresist-BM sensitive material, 70% by weight of propylene glycol methyl ether acetate (excluding propylene glycol methyl ether acetate contained in photoresist) and 10% solid impurities by weight.

[0064] like figure 1 As shown, the mixed waste liquid to be recovered is introduced into the distillation tank for distillation to vaporize the solvent in the mixed waste liquid. During the distillation process, the distillation temperature is controlled at 160°C and the pressure is 30Pa. Cool and liquefy in the liquefaction cooling tank, filter and remove impurities in the filter, and the recovered solvent is introduced into the solvent recovery tank for storage. The results showed that the solvent recovery was 75%.

Embodiment 2

[0066] This example is used to illustrate the solvent recovery system and method provided by the present invention.

[0067] In this embodiment, the mixed waste liquid to be recovered contains 25% by weight of photoresist-OC material, 70% by weight of propylene glycol methyl ether acetate and 5% by weight of solid impurities.

[0068] like figure 1 As shown, the mixed waste liquid to be recovered is introduced into the distillation tank for distillation to vaporize the solvent in the mixed waste liquid. During the distillation process, the distillation temperature is controlled at 150°C and the pressure is 10Pa. Cool and liquefy in the liquefaction cooling tank, filter and remove impurities in the filter, and the recovered solvent is introduced into the solvent recovery tank for storage. The results showed that the solvent recovery was 78%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com