Rapid insulated gate bipolar transistor

A technology of bipolar transistors and insulated gates, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as complex external drive circuits and weak forward conduction capabilities of devices, so as to eliminate negative resistance effects and improve work stability , the effect of small off-time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The first conductivity type is selected as N type, and the second conductivity type is selected as P type.

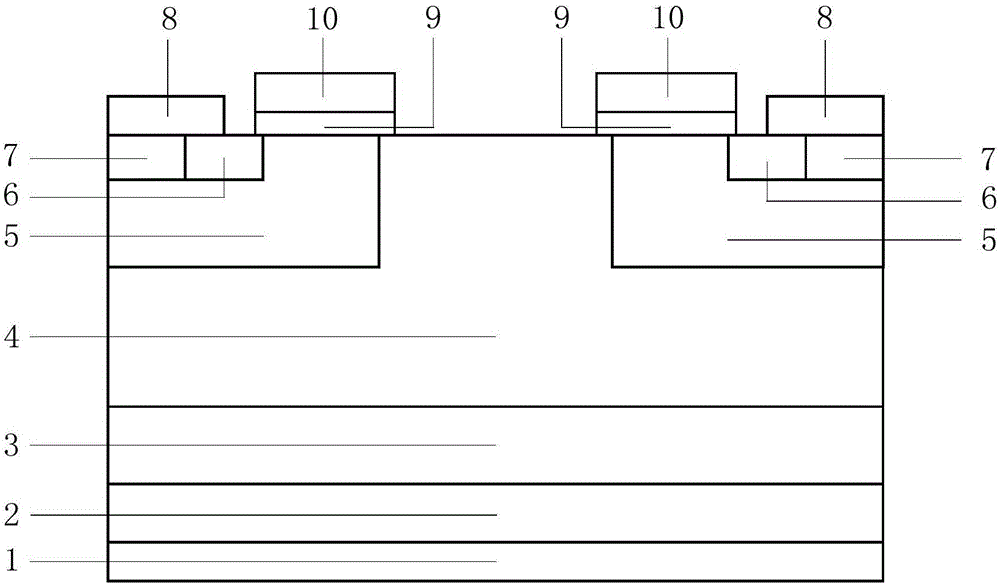

[0048] like Figure 4As shown, a fast insulated gate bipolar transistor is characterized in that it includes an anode contact area 1, a P+ type anode area 2, an N type anode buffer area 3, an N type drift area 4, a P type cathode well area 5, an N+ type cathode region 6, P+ type cathode region 7, cathode contact region 8, gate dielectric layer 9, gate contact region 10, P type anode well region 11, N+ type anode region 12, anode auxiliary gate dielectric layer 13 and anode auxiliary Gate contact region 14.

[0049] The N-type drift region 4 covers the N-type anode buffer zone 3 .

[0050] The P-type cathode well region 5 covers part of the surface above the N-type drift region 4 .

[0051] The N+ type cathode region 6 and the P+ type cathode region 7 cover part of the surface above the P type cathode well region 5 .

[0052] The cathode contact region 8 cover...

Embodiment 2

[0062] The first conductivity type is selected as N type, and the second conductivity type is selected as P type.

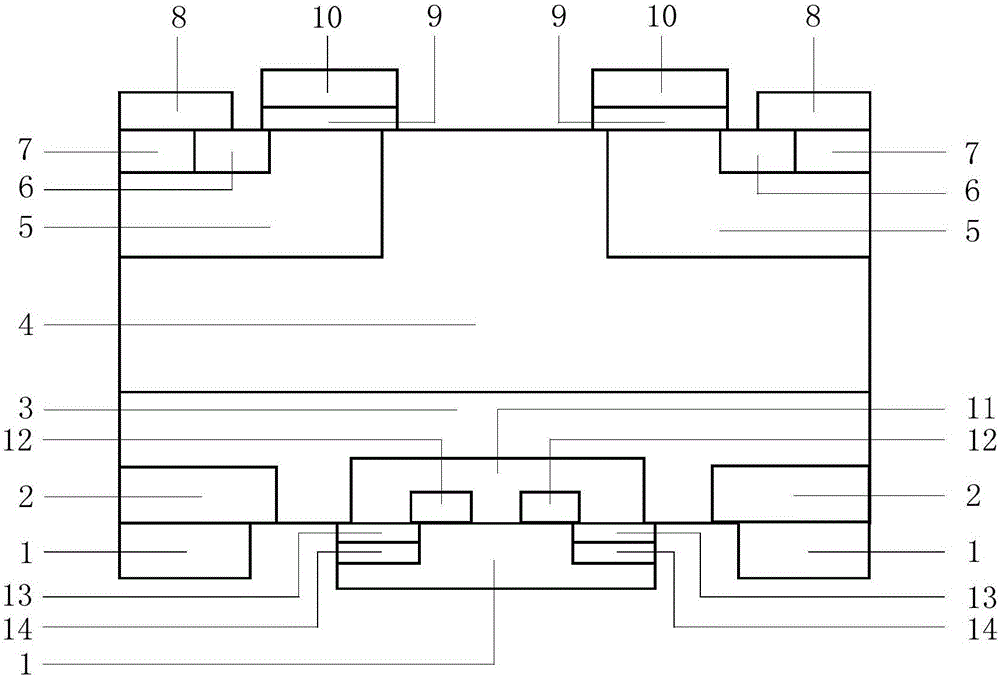

[0063] like Figure 5 As shown, a fast insulated gate bipolar transistor is characterized in that it includes an anode contact area 1, a P+ type anode area 2, an N type anode buffer area 3, an N type drift area 4, a P type cathode well area 5, an N+ Type cathode region 6, P+ type cathode region 7, cathode contact region 8, gate dielectric layer 9, gate contact region 10, P type anode well region 11, N+ type anode region 12 and anode auxiliary gate dielectric layer 13.

[0064] The N-type drift region 4 covers the N-type anode buffer zone 3 .

[0065] The P-type cathode well region 5 covers part of the surface above the N-type drift region 4 .

[0066] The N+ type cathode region 6 and the P+ type cathode region 7 cover part of the surface above the P type cathode well region 5 .

[0067] The cathode contact region 8 covers the P+ type cathode region 7 , and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com