Uni-traveling-carrier photodetector structure and manufacturing method thereof

A single-row carrier and photodetector technology, used in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as increasing the RC response bandwidth of devices, and achieve a controllable and large collection layer area reduction. Responsiveness, effect of large RC response bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] This embodiment provides a method for manufacturing a single row carrier photodetector, the method comprising:

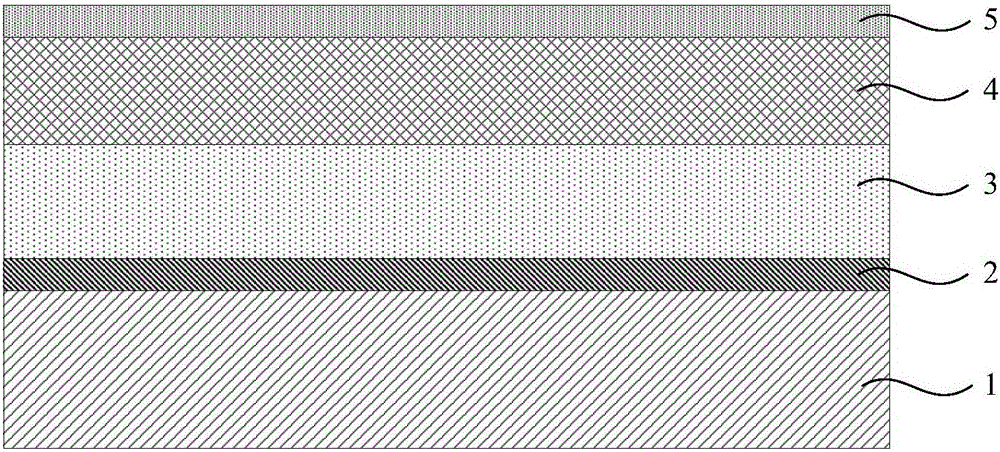

[0059] S1: growing an N-type heavily doped lower contact layer, a collection layer, an absorber layer, and a P-type heavily doped upper contact layer sequentially from bottom to top on a semi-insulating substrate;

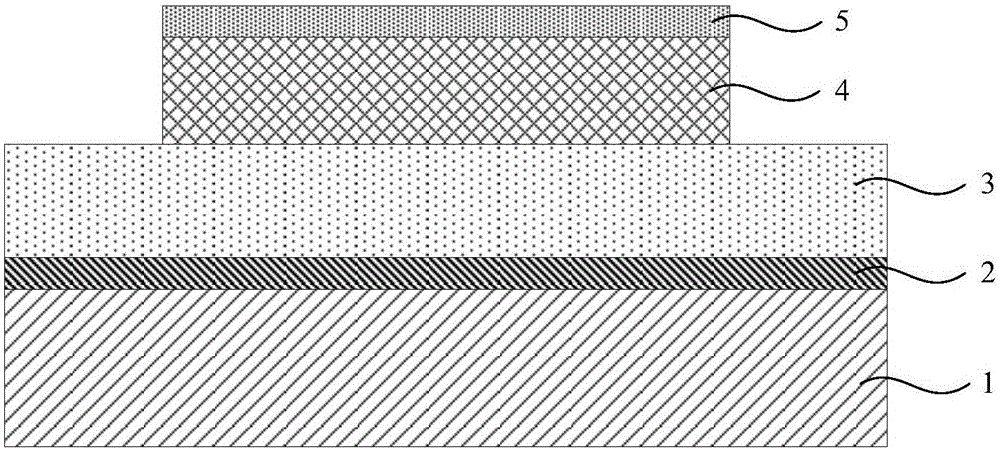

[0060] S2: performing photolithography on the structure described in S1, and using a selective etching solution to etch the P-type heavily doped upper contact layer and the absorber layer to expose part of the collection layer;

[0061] S3: growing a silicon nitride layer on the upper surface of the structure described in S2, and removing the silicon nitride layer on the upper surface of the collection layer by photolithography;

[0062] S4: Using a selective etching solution to etch the collection layer so that the area of the collection layer is equal to the area of the absorption layer, and then continue to corrode the collection layer unti...

Embodiment 2

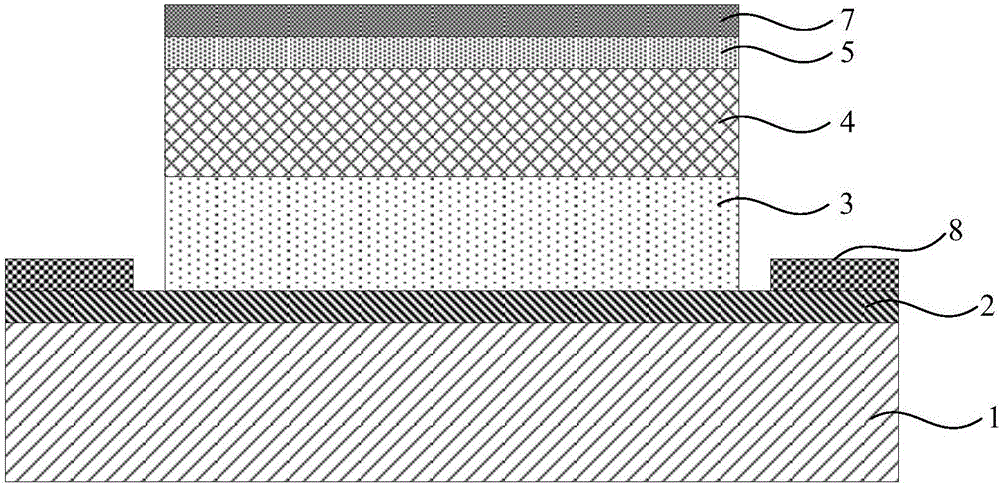

[0085] Such as Figure 9 with Figure 10 As shown, this embodiment provides a single row carrier photodetector structure, and the photodetector structure includes:

[0086] semi-insulating substrate 1;

[0087] An N-type heavily doped lower contact layer 2 located on the upper surface of the semi-insulating substrate 1;

[0088] A collection layer 3 located on the upper surface of the N-type heavily doped lower contact layer 2;

[0089] The lower electrode metal layer 8 located on the upper surface of the N-type heavily doped lower contact layer 2 and on both sides of the collection layer 3;

[0090] An absorbing layer 4 located on the upper surface of the collecting layer 3;

[0091] a P-type heavily doped upper contact layer 5 located on the upper surface of the absorber layer 4; and

[0092] The upper electrode metal layer 7 located on the upper surface of the P-type heavily doped upper contact layer 5;

[0093] Wherein, the area of the collecting layer 3 is smaller...

Embodiment 3

[0098] This embodiment provides a method for manufacturing a single row carrier photodetector, the method comprising:

[0099] S1: Grow a waveguide layer, N-type heavily doped lower contact layer, collection layer, absorber layer, and P-type heavily doped upper contact layer sequentially from bottom to top on a semi-insulating substrate;

[0100] S2: performing photolithography on the structure described in S1, and using a selective etching solution to etch the P-type heavily doped upper contact layer and the absorber layer to expose part of the collection layer;

[0101] S3: growing a silicon nitride layer on the upper surface of the structure described in S2, and removing the silicon nitride layer on the upper surface of the collection layer by photolithography;

[0102] S4: Using a selective etching solution to etch the collection layer so that the area of the collection layer is equal to the area of the absorption layer, and then continue to corrode the collection laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com