Lithium-containing negative plate and preparation method thereof

A technology for lithium negative electrodes and pole pieces, which is applied in the field of lithium-containing negative electrodes and its preparation, can solve the problems of limited improvement, low discharge capacity, and difficult application, and achieves good current collection and heat dissipation effects, simple preparation methods, and reproducibility. highly operable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

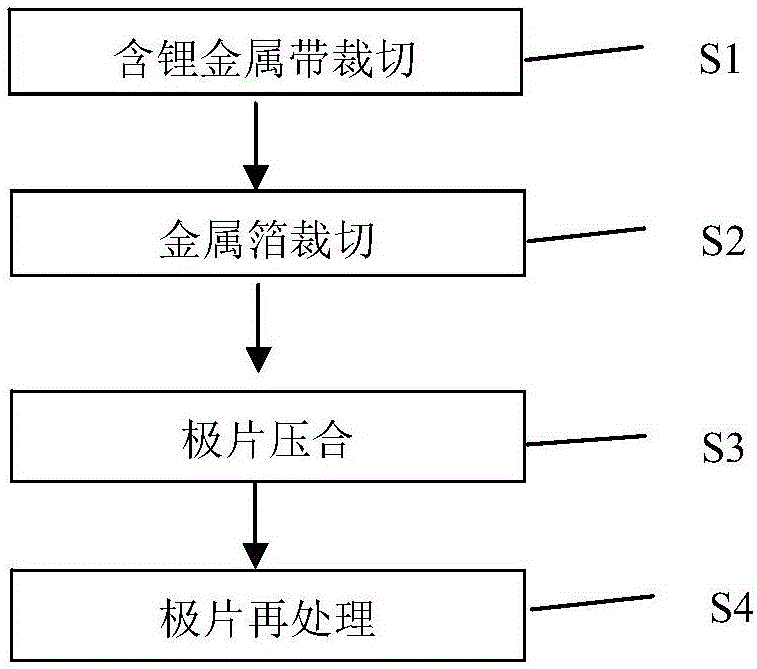

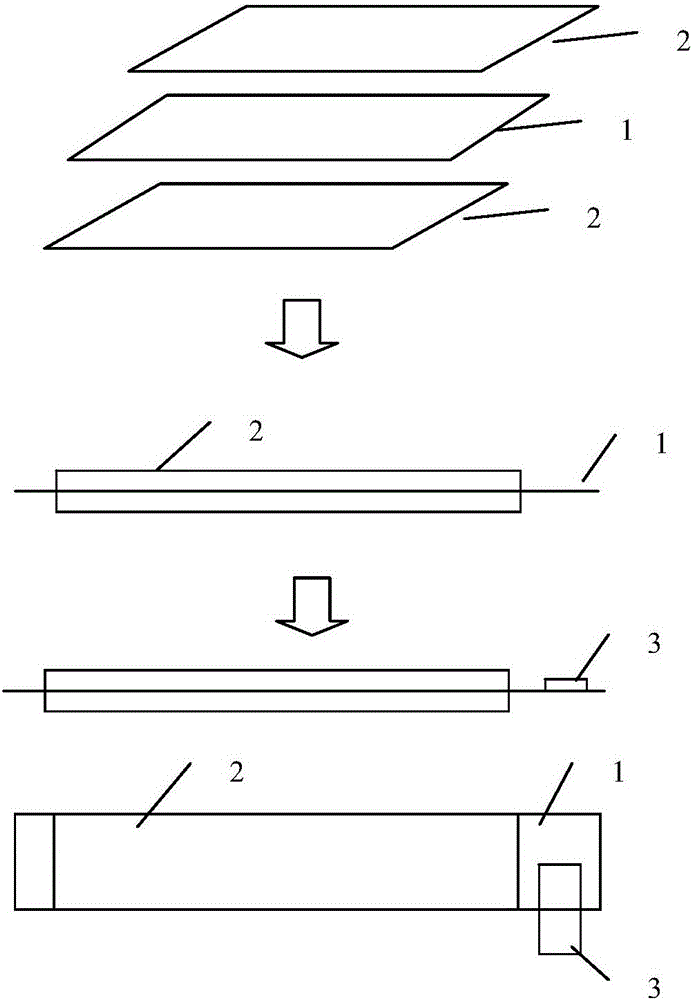

[0037] Such as figure 2 As shown, the lithium-containing negative electrode sheet described in this embodiment is prepared by the following method:

[0038] (1) Lithium ribbon cutting: Cut the 0.05mm thick lithium ribbon into 60mm wide*1000mm long.

[0039] (2) Metal foil cutting: cut metal copper foil into 62mm wide * 1050mm long, the mechanical thickness of the copper foil is 15μm, both sides of the copper foil are oxidized and roughened, and the specific surface area of the copper foil is increased by 100 after roughening times, the surface microstructure is particle protrusions, the roughness Ra is about 1.4 μm, and Rz is about 4.5.

[0040] (3) Electrode lamination: Use flat lamination equipment, the effective size of the upper and lower lamination plates is 150mm*200mm, and the equipment pressure is set at 0.5MPa; the pole piece is prepared with a sandwich structure of two layers of lithium sandwiched by a layer of copper foil , and wrap the upper and lower parts of...

Embodiment 2

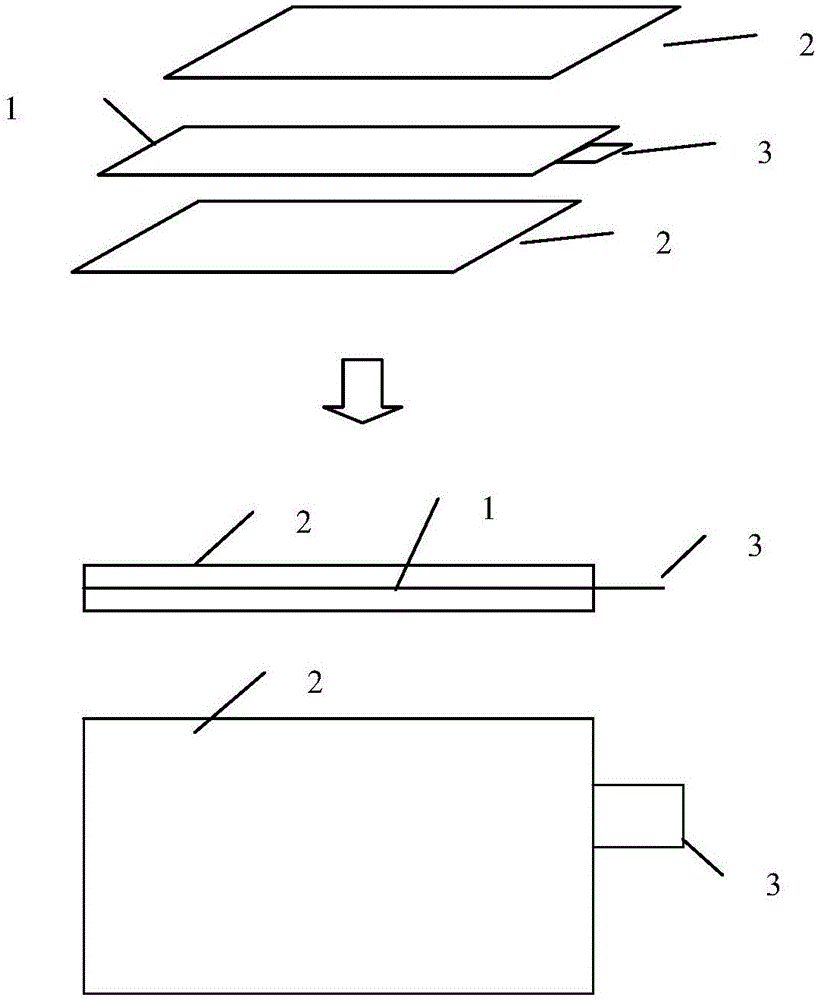

[0043] Such as image 3 As shown, the lithium-containing negative electrode sheet described in this embodiment is prepared by the following method:

[0044] (1) Lithium ribbon cutting: Cut the 0.05mm thick lithium ribbon into 60mm wide*80mm long.

[0045](2) Metal foil cutting: The metal copper foil is processed into irregular small pieces with a punching die and a punching knife, consisting of two squares. The size of the large square is 62mm wide * 82mm long (bonded with the lithium sheet); the small square size is 15mm * 10mm, which is used as the tab for current collection. The mechanical thickness of the metal copper foil is 10 μm, and both sides of the copper foil are oxidized and roughened. After roughening, the specific surface area of the copper foil is increased by about 100 times. is 3.6.

[0046] (3) Pole piece lamination: Plane lamination equipment is used, the effective size of the upper and lower lamination plates is 150mm*200mm, and the equipment pressure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com