Positive electrode plate of lithium ion battery and preparation method for positive electrode plate

A technology for lithium-ion batteries and positive plates, applied in battery electrodes, electrode carriers/current collectors, circuits, etc., can solve problems affecting the overall performance of materials, lack of liquid absorption and holding capacity, and reduce battery conductivity, etc., to achieve active The effect of high substance content, good electrical conductivity and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

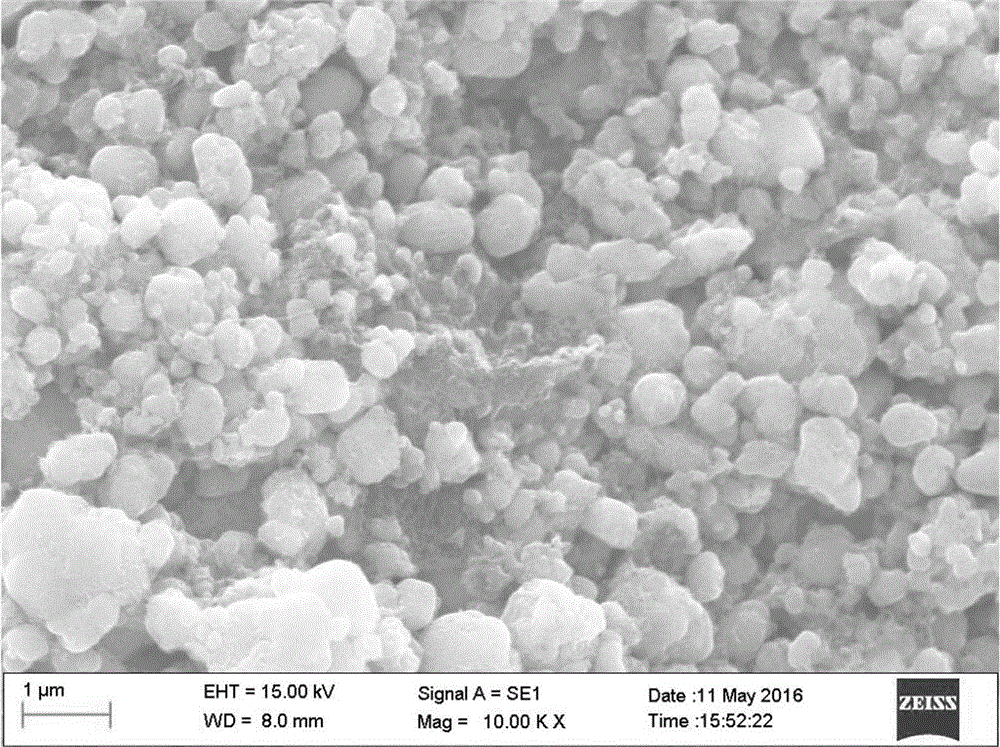

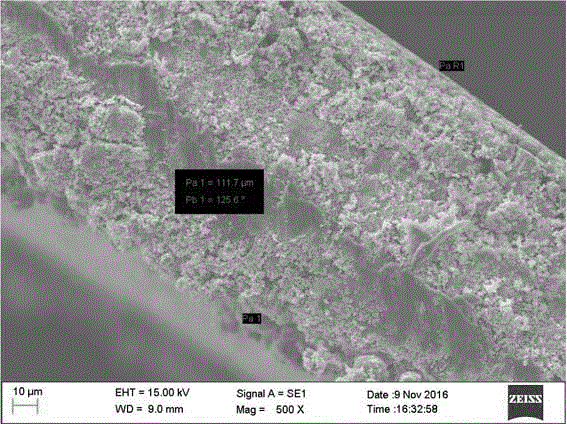

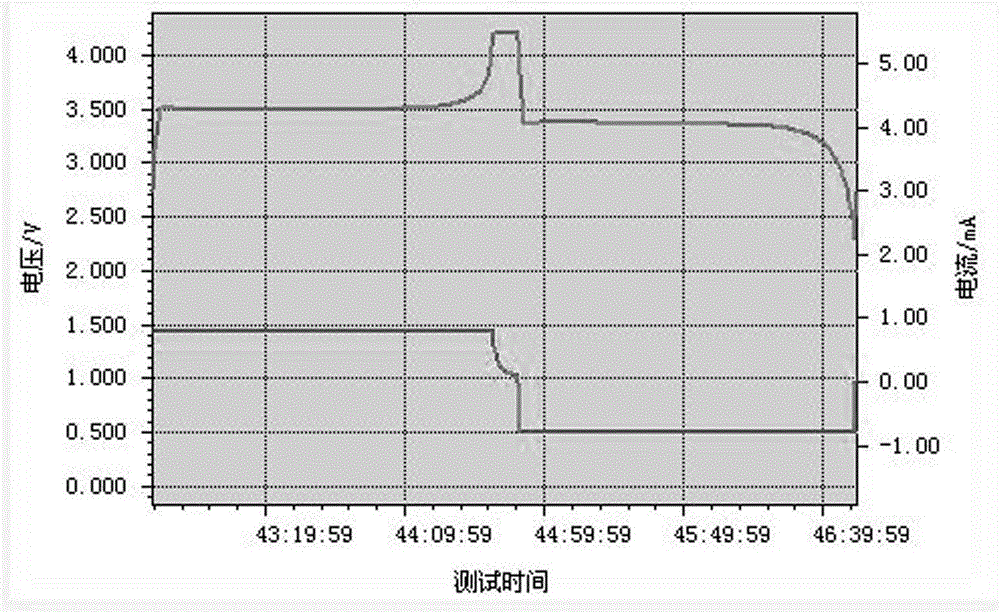

[0016] A lithium ion battery positive electrode sheet, the positive electrode sheet is composed of a positive electrode active material, a conductive agent, a binder, and a current collector, the positive electrode active material is lithium iron phosphate, the conductive agent is carbon nanofiber, and the binder is polyvinylidene fluoride, The current collector is made of carbon fiber composite non-woven fabric, and the nano-carbon fiber is evenly dispersed in the organic solvent N-methylpyrrolidone and introduced into the non-woven fabric by high-temperature drying and pressing to obtain a carbon fiber composite non-woven fabric current collector. The thickness of the current collector is 20±1μm , mix the positive electrode active material, conductive agent nano-carbon fiber, binder polyvinylidene fluoride and organic solvent evenly to make positive electrode slurry, the mass ratio of positive electrode active material, conductive agent nano-carbon fiber, and binder polyvinyli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com