Wide-speed sliding-mode observer of sensorless brushless direct-current motor

A technology of brushed DC motor and mode observer, which is applied in the direction of electronically commutated motor control, electrical components, control systems, etc., can solve problems such as inability to eliminate inherent chattering, complex algorithms and structures, and too sensitive parameters, so as to improve observation The effect of range and estimation accuracy, simple implementation method, and simple adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

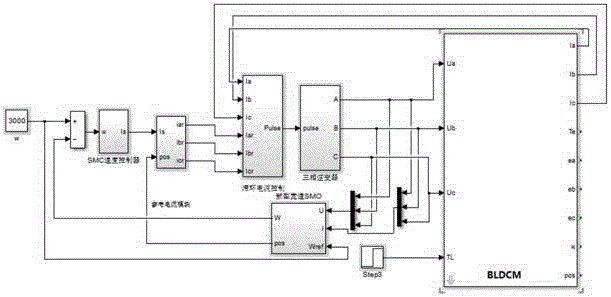

[0036] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0037] The invention provides a wide-speed sliding mode observer of a position sensorless brushless direct current motor, which is based on the traditional sliding mode observer and improves the sliding mode observer in a position sensorless brushless direct current motor speed control system.

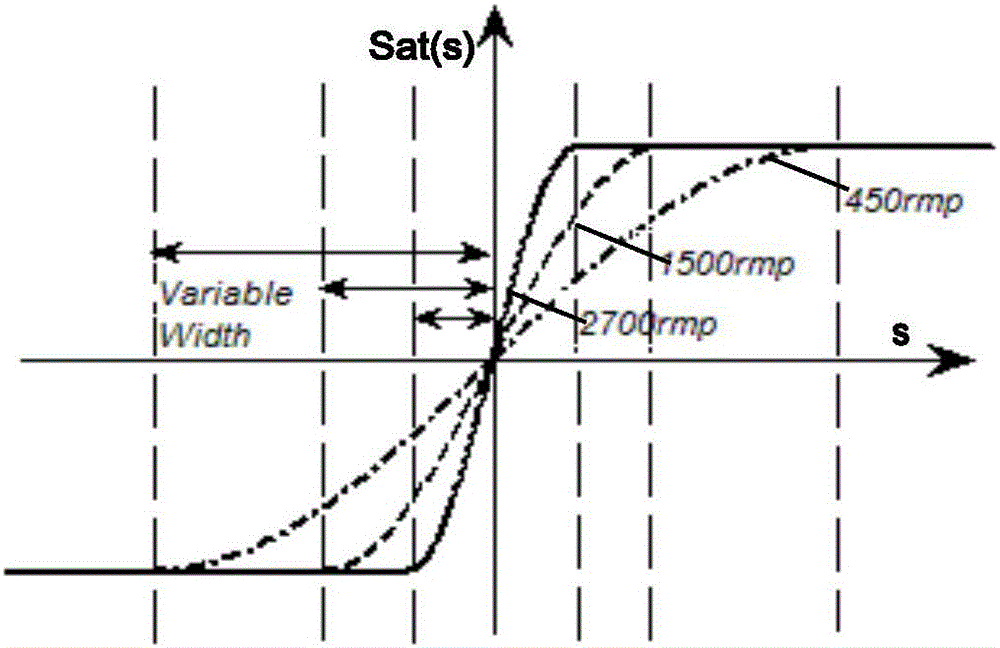

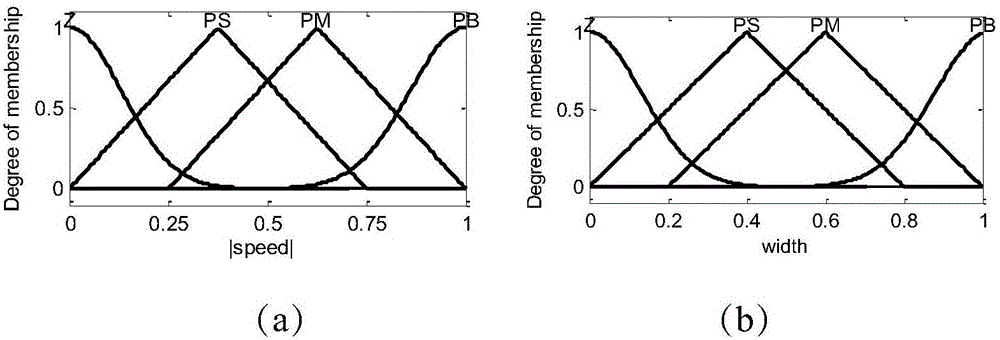

[0038] In a position sensorless control system, the traditional sliding mode observer usually uses Signum function and Sigmoid function as the sliding surface function. The Signum function needs to cooperate with a low-pass filter to achieve the purpose of suppressing jitter, which brings serious phase delay and reduces the estimation accuracy. Compared with the Signum function, the Sigmoid function can suppress the inherent chattering of the sliding mode and avoid the serious phase delay caused by the use of the low-pass filter, but it has the following problems: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com