an al 2 o 3 -ce 2 o 3 /sba-15 mesoporous silicon-based material and preparation method thereof

An al2o3-ce2o3, mesoporous silicon technology, applied in the field of materials, can solve problems such as uneven distribution and damage to mesoporous structure, and achieve the effects of easy operation, good thermal stability and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

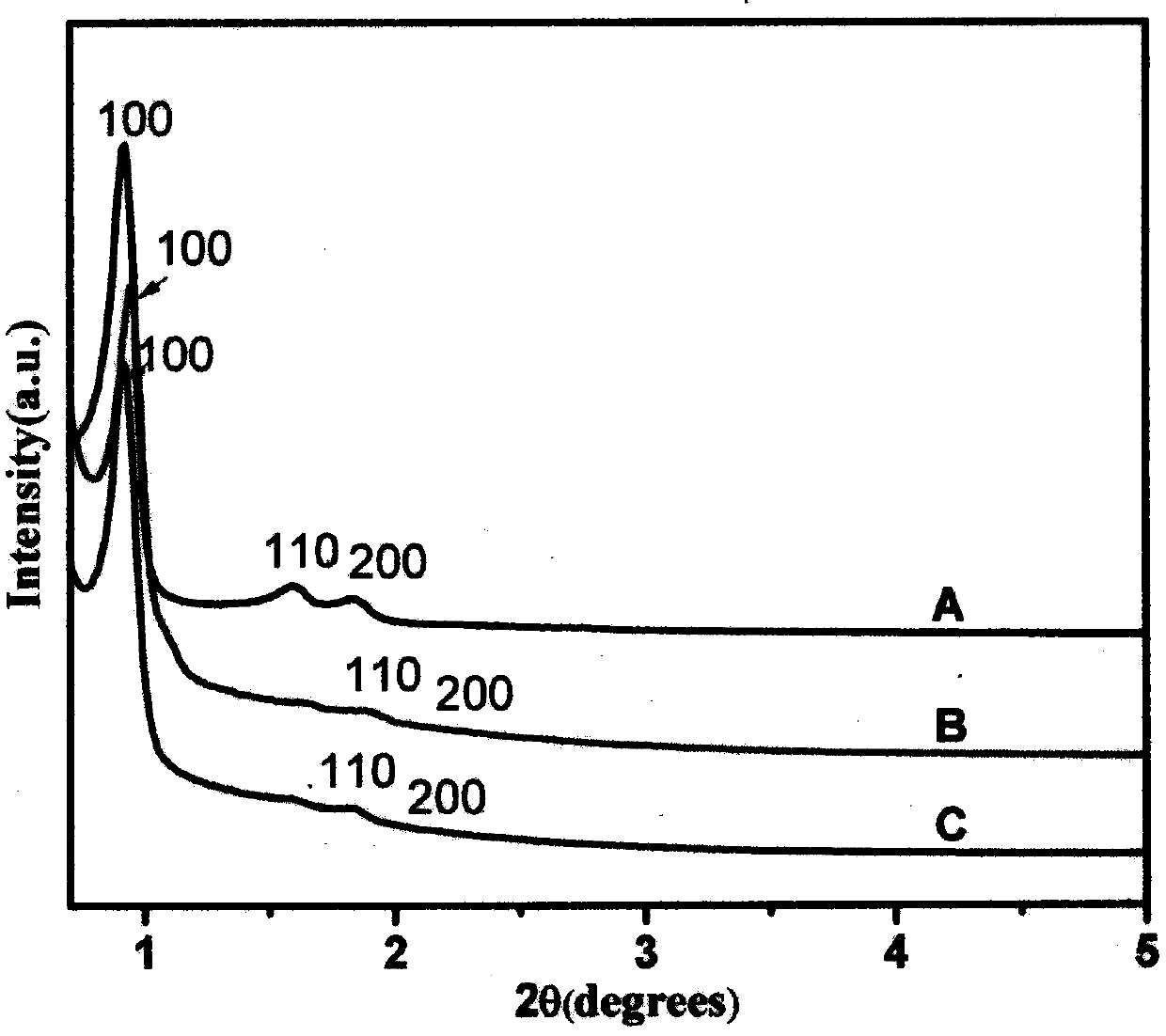

[0028] Example 1 2.14gAl (NO 3 ) 3 9H 2 O and 19.78g Ce(NO 3 ) 3 ·6H 2 Dissolve O together in 119mL of absolute ethanol, stir at 40°C for 3h to obtain mixed liquid A; Solution B: Slowly add the mixed solution A to the mixed solution B, stir at 40°C for 3h, then transfer to a stainless steel hydrothermal kettle lined with polytetrafluoroethylene, and crystallize at 110°C for 5h to form a crystal Chemical mixture I. Dissolve 10.35g of polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer in 384.5g of 1.6mol / L hydrochloric acid at 40°C, stir vigorously for 3 hours, then add 21.97g of orthosilicon Acid ethyl ester reagent, continue to stir for 12h, the formation of mixture II. Slowly add the crystallized mixture I to the mixture II under stirring, stir and mix for 6 hours, transfer to a polytetrafluoroethylene-lined stainless steel hydrothermal kettle, and crystallize at 100°C for 48 hours; filter the obtained mixed system, After washing and drying, ...

Embodiment 2

[0029] Example 2 The experimental procedure is the same as that of Example 1, the difference being that Al(NO 3 ) 3 9H 2 O, Ce(NO 3 ) 3 ·6H 2 O is 6.425g and 14.43g respectively, and the others remain unchanged. What is produced is Al with a mass molar ratio of Al, Ce, and Si elements of 0.167:0.333:1 2 o 3 -Ce 2 o 3 / SBA-15 mesoporous silicon-based material 12.56g, accounting for 99.52% of the mass percentage of Al, Ce, and Si oxides in the feed, indicating that the prepared Al 2 o 3 -Ce 2 o 3 / SBA-15 mesoporous silicon-based material has little loss after hydrothermal and calcination process, and has good stability. The analysis and characterization of BET, FT-IR, XRD, SEM, and TEM show that its mesoporous structure is damaged to a certain extent, and SBA There are many agglomerations on the -15 mesoporous surface.

Embodiment 3

[0030] Example 3 The experimental procedure is the same as in Example 1, the difference being that the Al(NO 3 ) 3 9H 2 O, Ce(NO 3 ) 3 ·6H 2 The masses of O are 4.8g and 16.7g respectively, and the others remain unchanged. What is produced is Al with a mass molar ratio of Al, Ce, and Si elements of 0.125:0.375:1 2 o 3 -Ce 2 o 3 / SBA-15 mesoporous silicon-based material 13.03g, accounting for 99.39% of the mass percentage of Al, Ce, and Si oxides in the feed, indicating that the prepared Al 2 o 3 -Ce 2 o 3 / SBA-15 mesoporous silicon-based material has little loss after hydrothermal and calcination process, and has good stability. It has been analyzed and characterized by BET, FT-IR, XRD, SEM, and TEM, showing that its mesoporous structure has been damaged, and SBA -15 mesoporous surface has some agglomeration phenomenon, but all slow down than embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com