Co oxide/BaCO3 catalyst for N2O catalytic decomposition and preparation method thereof

A catalytic decomposition and catalyst technology, which is applied in physical/chemical process catalysts, separation methods, chemical instruments and methods, etc., can solve the problems of low alkaline earth metal content, high cost, and no assistance, and can reduce high cost, improve activity, The effect of reducing coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

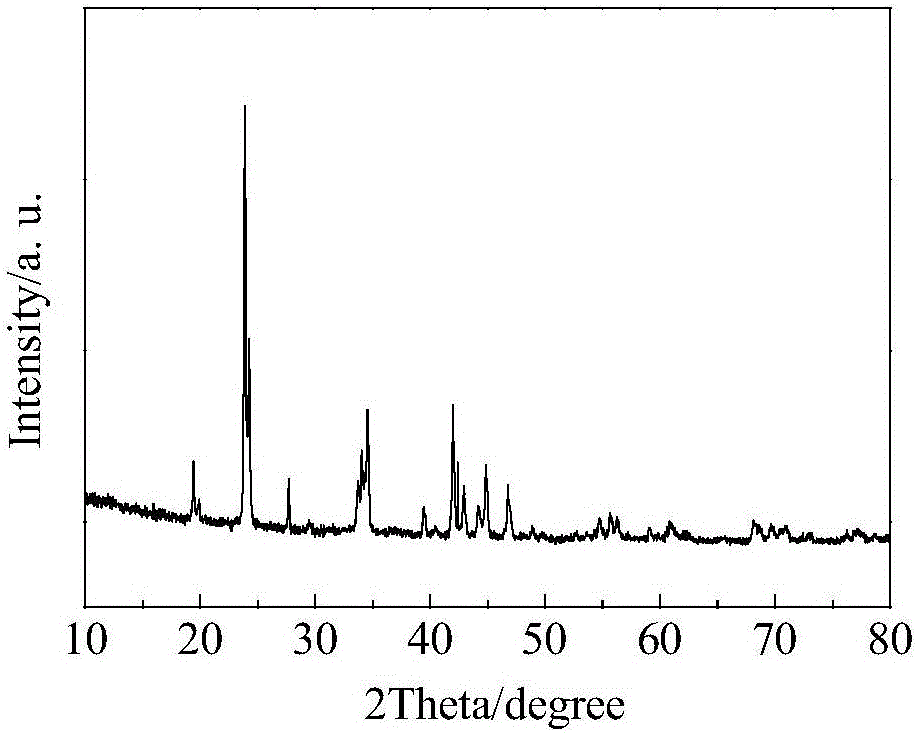

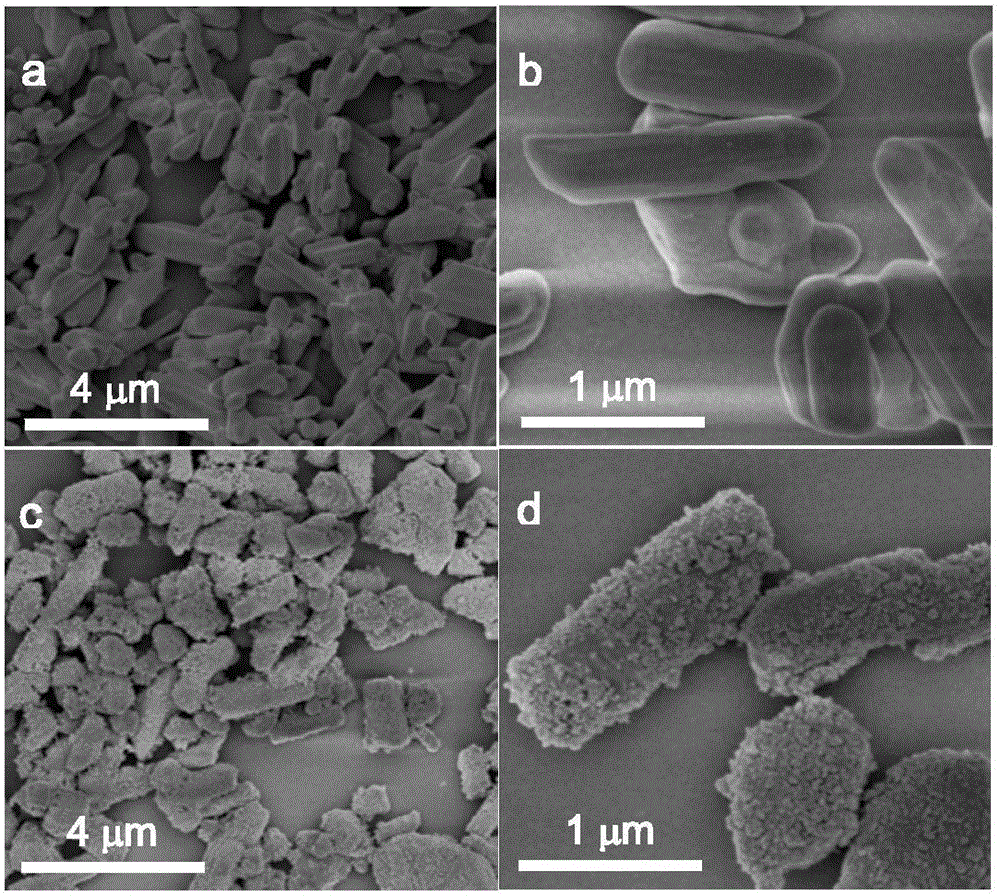

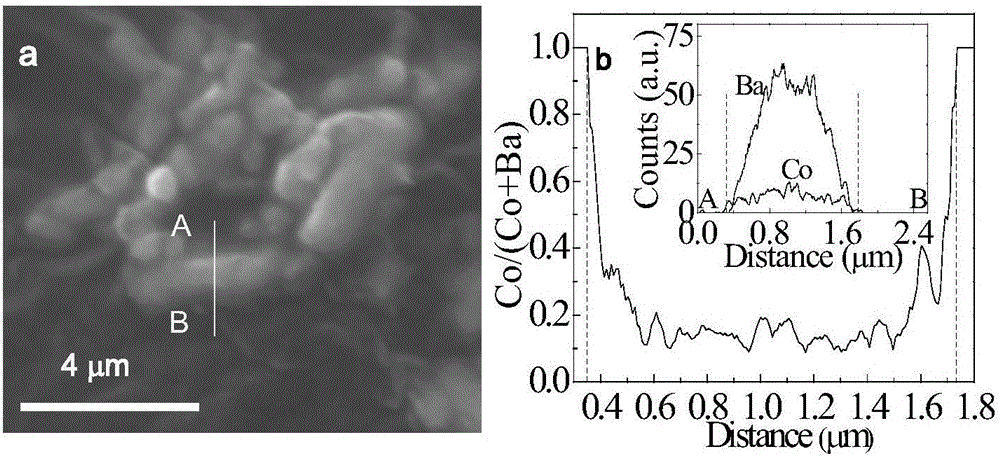

Embodiment 1

[0063] 1.0 g BaCO 3 Carrier powder (the measured surface area is 2.3m 2 / g) placed in 50ml of Co(NO 3 ) 2 ·6H 2 O aqueous solution, stirred at this temperature for 3 hours, then the solid obtained by adsorption and deposition was separated by suction filtration, washed with distilled water until neutral, dried at 110°C, and calcined at 500°C in air for 3 hours to obtain a Co oxide shell / BaCO 3 Catalyst powder. Then the catalyst powder is pressed into tablets, crushed and sieved to make 40-60 mesh Co oxide shell / BaCO 3 Catalyst, its measured surface area is 4.7m 2 / g.

Embodiment 2

[0065] Repeat Example 1, but with 25ml concentration of 0.2M Co(NO 3 ) 2 ·6H 2 O aqueous solution instead of 50ml concentration in embodiment 1 is 0.1M Co(NO 3 ) 2 ·6H 2 O aqueous solution. The specific surface of the obtained catalyst is 5.2m 2 / g.

Embodiment 3

[0067] Repeat Example 1, but with 12.5ml concentration of 0.4M Co(NO 3 ) 2 ·6H 2 O aqueous solution instead of 50ml concentration in embodiment 1 is 0.1M Co(NO 3 ) 2 ·6H 2 O aqueous solution. The specific surface of the obtained catalyst is 5.3m 2 / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com