Permanent magnet speed regulation system of power plant auxiliary equipment

A permanent magnet speed regulation and auxiliary machine technology, applied in the control/regulation system, general control system, computer control, etc., can solve the problems of reducing the reliability of the frequency conversion system, increasing the power electronic equipment, complex circuit structure, etc., to achieve a smooth start Overload protection function, reducing vibration, and the effect of low operating failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

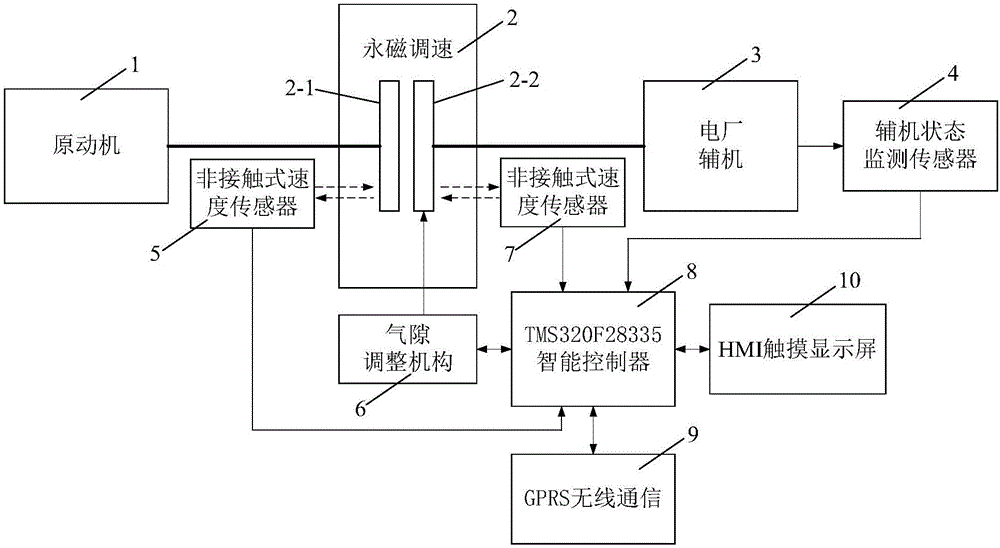

[0035] Such as figure 1 As shown, a permanent magnet speed control system for power plant auxiliary equipment provided by the present invention includes a prime mover 1, a permanent magnet speed control module 2, a power plant auxiliary machine 3, a first non-contact speed sensor 5, a second non-contact speed sensor Sensor 7, auxiliary machine status monitoring sensor 4, air gap adjustment mechanism 6, TMS320F28335 intelligent controller 8, GPRS wireless communication module 9 and HMI touch screen 10; wherein, the permanent magnet speed regulating module 2 includes a conductor rotor 2- 1 and the permanent magnet rotor 2-2, the prime mover 1 is connected to the conductor rotor 2-1 of the permanent magnet speed regulating module 2 through the motor shaft, and the permanent magnet rotor 2-2 of the permanent magnet speed regulating module 2 is connected to the auxiliary po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com