Anode material for lithium metal batteries

A technology for lithium metal batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of unfavorable commercial production, increase the overall weight of the battery, cumbersome preparation process, etc., and achieve increased cycle performance and safety. The effect of controllable thickness and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

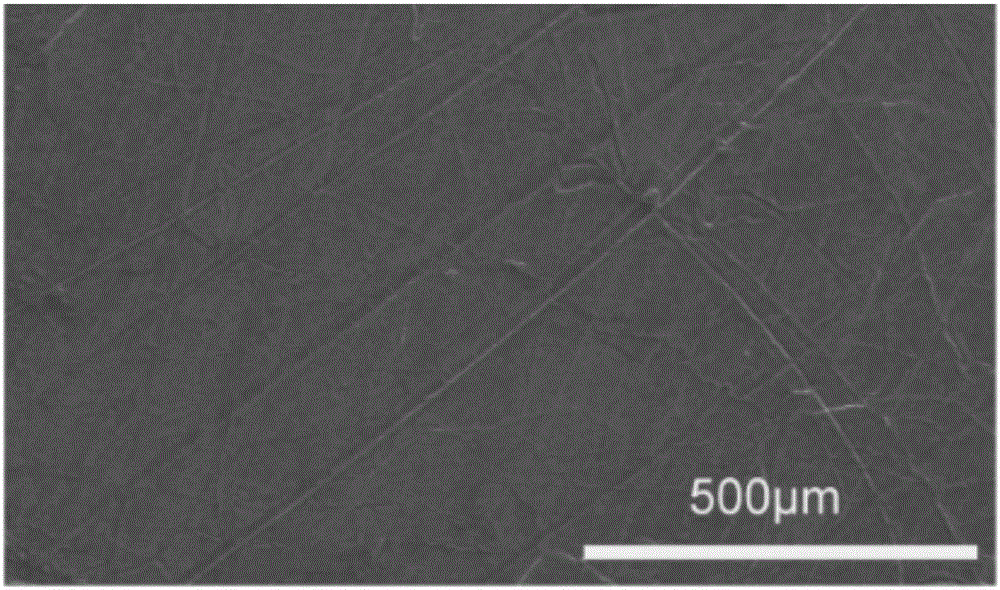

[0027] With LiF as the target material and lithium sheet as the substrate, the magnetron sputtering power is set to 80W, the air pressure is set to 10mTorr, and the time is set to 20min, a LiF film with a thickness of 150nm is deposited on the surface of the lithium sheet, which is used for lithium The anode material of the metal battery, its SEM image is shown in figure 1 .

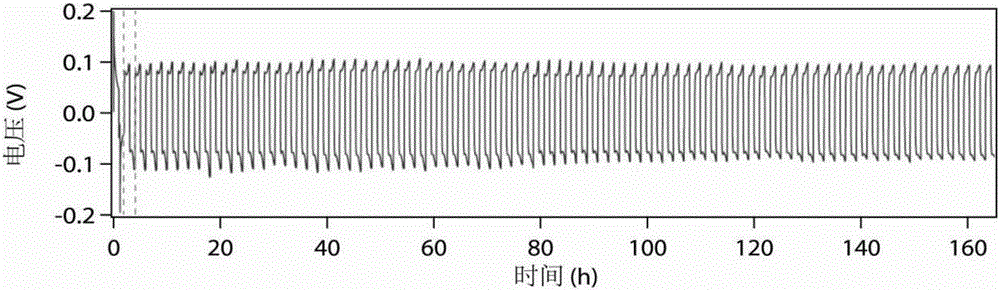

[0028] The negative electrode material prepared in this embodiment is used as an electrode of a lithium metal symmetric battery, and PC with 1M lithium bistrifluoromethanesulfonimide (LiTFSI) added is used as an electrolyte. Cell assembly was performed in an argon-protected glove box using a 2032-size coin cell. The current density of the galvanostatic test is 1mA cm -2 , with a capacity of 1mAh cm -2 , performance see figure 2 .

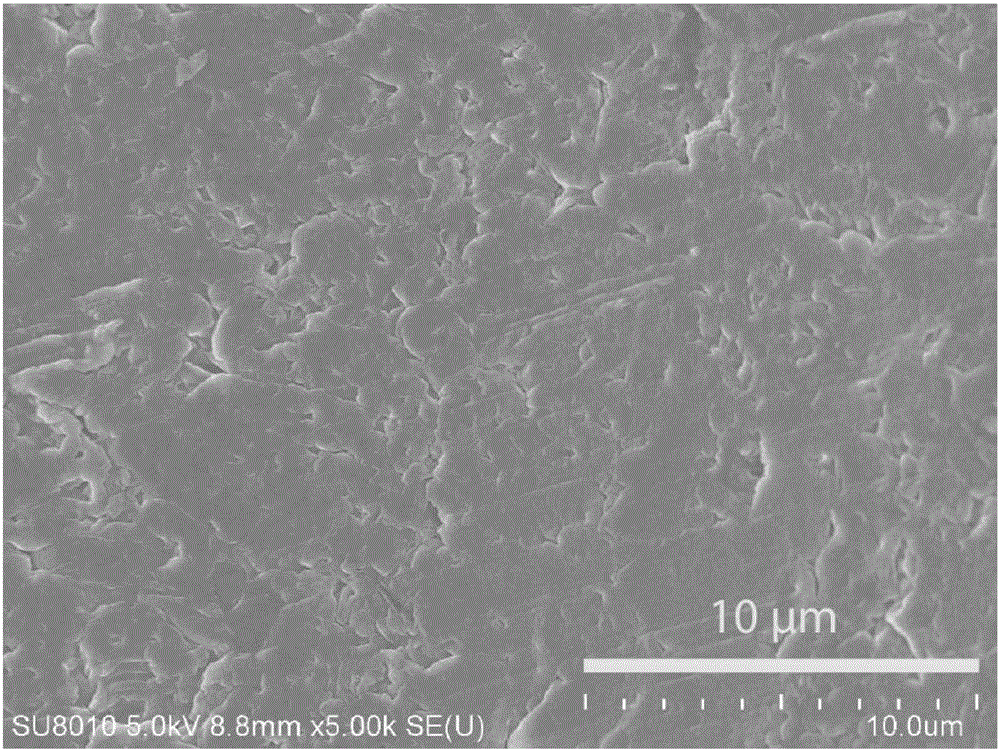

[0029] After 10 cycles, the SEM image of the negative electrode material is as follows: image 3 shown, observe image 3 It can be seen that no lithium textured crysta...

Embodiment 2

[0031] With LiF as the target material and lithium sheet as the substrate, the magnetron sputtering power is set to 80W, the air pressure is set to 10mTorr, and the time is set to 10min, a LiF film with a thickness of 75nm is deposited on the surface of the lithium sheet, which is used for lithium The negative electrode material of the metal battery, its SEM picture is similar to embodiment 1.

[0032] The negative electrode material prepared in this example is the electrode of a lithium metal symmetric battery. The lithium metal battery was assembled with reference to the raw materials and assembly process in Example 1. After testing, the performance was similar to that in Example 2. The current density of the galvanostatic test is 1mA cm -2 , with a capacity of 1mAh cm -2 , performance see Figure 4 .

[0033] After 10 cycles, the SEM image of the negative electrode material is similar to that of Example 1.

Embodiment 3

[0035] With LiF as the target and lithium sheet as the substrate, the power of magnetron sputtering is set to 100W, the air pressure is set to 10mTorr, and the time is set to 50min, a LiF film with a thickness of 500nm is deposited on the surface of the lithium sheet, which is used for lithium The negative electrode material of the metal battery, its SEM picture is similar to embodiment 1.

[0036] The negative electrode material prepared in this example is the electrode of a lithium metal symmetric battery. The lithium metal battery was assembled with reference to the raw materials and assembly process in Example 1. After testing, the performance was similar to that in Example 2. The current density of the galvanostatic test is 1mA cm -2 , with a capacity of 1mAh cm -2 , performance see Figure 5 .

[0037] After 10 cycles, the SEM image of the negative electrode material is as follows: Image 6 shown, observe Image 6 It can be seen that lithium textured crystals are fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com