A kind of zero additive coconut milk and preparation method thereof

A technology of coconut juice and additives, applied in the field of zero-additive coconut juice and its preparation, can solve the problems of incomplete reflection of coconut flavor, easy occurrence of slicks and flocs, lack of nutritional value, etc., and achieve easy large-scale production Promotion, taste fresh and refreshing, good taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

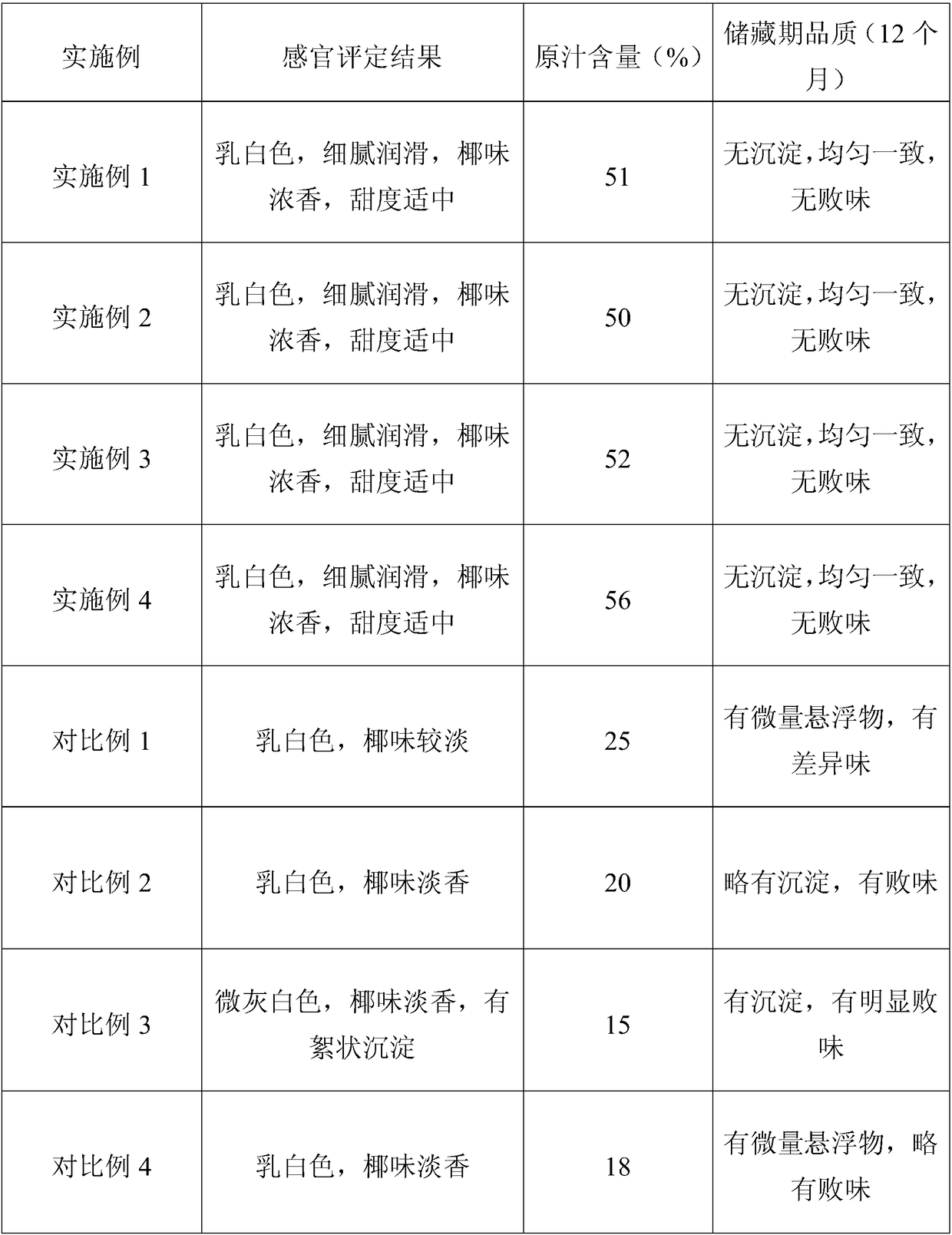

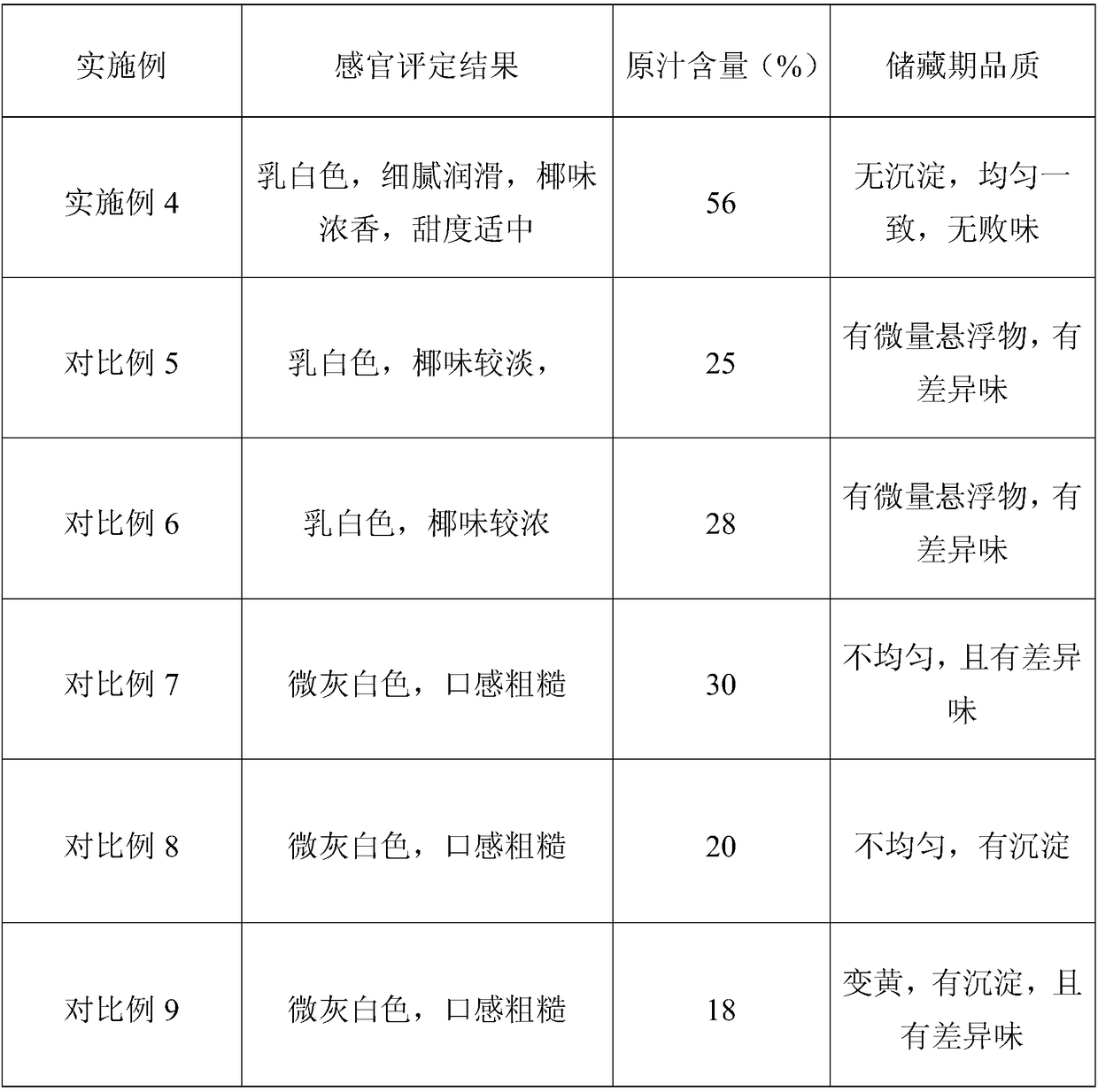

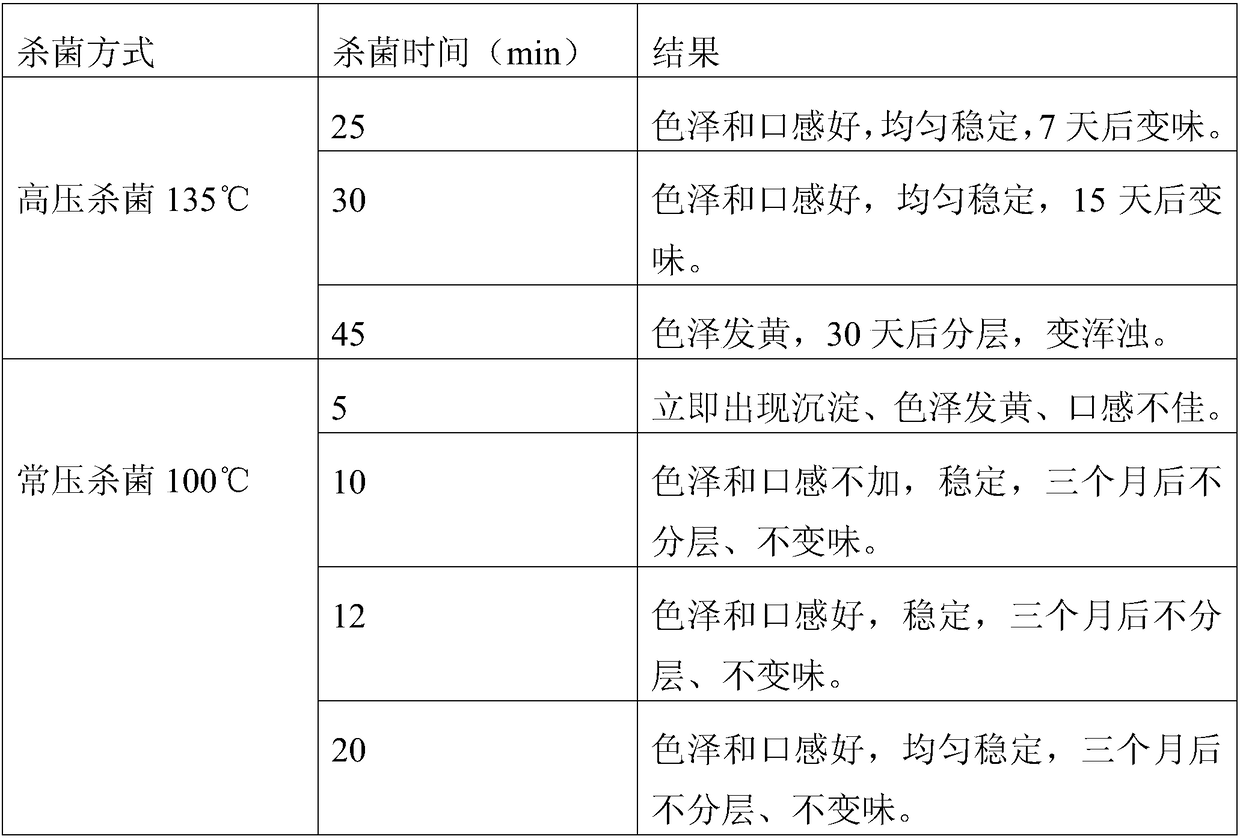

Examples

Embodiment 1

[0026] A kind of zero additive coconut juice, described coconut juice comprises the raw material of following weight content:

[0027] 20g of coconut milk, 6g of coconut water, 15g of white sugar and the rest of pure water.

[0028] A preparation method of zero-additive coconut juice, comprising the following steps:

[0029] S1, pretreatment: the fresh coconut meat is washed, dried, and subjected to high-speed mechanical crushing. The crushing speed is 4000r / min, and the crushing time is 5min.

[0030] S2. Juicing: Add the broken coconut meat to 3 times the volume of pure water to squeeze the juice, filter the filtrate and filter residue, and use a three-stage filter to filter, the first-stage filter has a mesh number of 90 mesh, and the second-stage filter The mesh number is 200 mesh, and the mesh number of the third-stage filter is 350 mesh. After filtering, the filtrate and filter residue are combined.

[0031] S3, leaching: the filter residue of step S2 is extracted with...

Embodiment 2

[0037] A kind of zero additive coconut juice, described coconut juice comprises the raw material of following weight content:

[0038] 30g of coconut milk, 10g of coconut water, 20g of white sugar and the rest of pure water.

[0039] A preparation method of zero-additive coconut juice, comprising the following steps:

[0040] S1, pretreatment: the fresh coconut meat is washed, dried, and subjected to high-speed mechanical crushing, the crushing speed is 8000r / min, and the crushing time is 10min.

[0041] S2. Juicing: Add the broken coconut meat to 5 times the volume of pure water to squeeze the juice, filter the filtrate and filter residue, and use a three-stage filter to filter, the first-stage filter has a mesh number of 100 mesh, and the second-stage filter The mesh number is 250 mesh, and the mesh number of the third-stage filter is 400 mesh. After filtering, the filtrate and filter residue are combined.

[0042] S3, leaching: extract the filter residue of step S2 with a...

Embodiment 3

[0048] A kind of zero additive coconut juice, described coconut juice comprises the raw material of following percentage by weight:

[0049] 24g of coconut milk, 8g of coconut water, 18g of white sugar and the rest of pure water.

[0050] A preparation method of zero-additive coconut juice, comprising the following steps:

[0051] S1, pretreatment: wash fresh coconut meat, dry, carry out high-speed mechanical crushing, the crushing speed is 7000r / min, and the crushing time is 8min.

[0052] S2. Juicing: Add the broken coconut meat to 4 times the volume of pure water to squeeze the juice, filter the filtrate and filter residue, filter with a three-stage filter, the first-stage filter has a mesh number of 90 mesh, and the second-stage filter The mesh number is 200 mesh, and the mesh number of the third-stage filter is 350 mesh. After filtering, the filtrate and filter residue are combined.

[0053]S3, leaching: extract the filter residue of step S2 with an aqueous ethanol solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com