Preparation method of lanthanum ferrite doped silver bromide compound photocatalyst

A technology of lanthanum ferrite and silver bromide, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of limited application and research, poor photosensitivity and stability, and meet the preparation conditions Easy to control, simple preparation method, high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) In a beaker, dissolve 1.2g of lanthanum nitrate, 1.6g of ferric nitrate and 1.6g of citric acid in 100ml of water, heat to 60°C and stir for 30min, adjust the pH value to 6 with ammonia water, form a gel, and dry at 60°C 6h, put it into a muffle furnace, sinter at 500°C for 2h, and grind to get lanthanum ferrite.

[0022] (2) Disperse 0.018g of lanthanum ferrite in step (1) in 20ml of absolute ethanol, ultrasonicate for 30min, add 0.18g of silver nitrate, stir for 30min, then add 0.108g of potassium bromide, stir for 30min, centrifuge, wash, Dry at 60°C for 4h.

Embodiment 2

[0024] (1) In a beaker, dissolve 0.56g of lanthanum nitrate, 1.6g of ferric nitrate and 0.8g of citric acid in 50ml of ethanol, heat to 80°C and stir for 60min, adjust the pH value to 8 with ammonia water, and form a gel at 80°C Dry for 12 hours, put it in a muffle furnace, sinter at 600°C for 3 hours, and grind to get lanthanum ferrite.

[0025] (2) Disperse 0.072g of lanthanum ferrite in step (1) in 30ml of deionized water, sonicate for 60min, add 0.18g of silver nitrate, stir for 60min, then add 0.126g of sodium bromide, stir for 60min, centrifuge, wash, Dry at 80°C for 6h.

[0026] 1. Performance determination of lanthanum ferrite / silver bromide composite photocatalyst

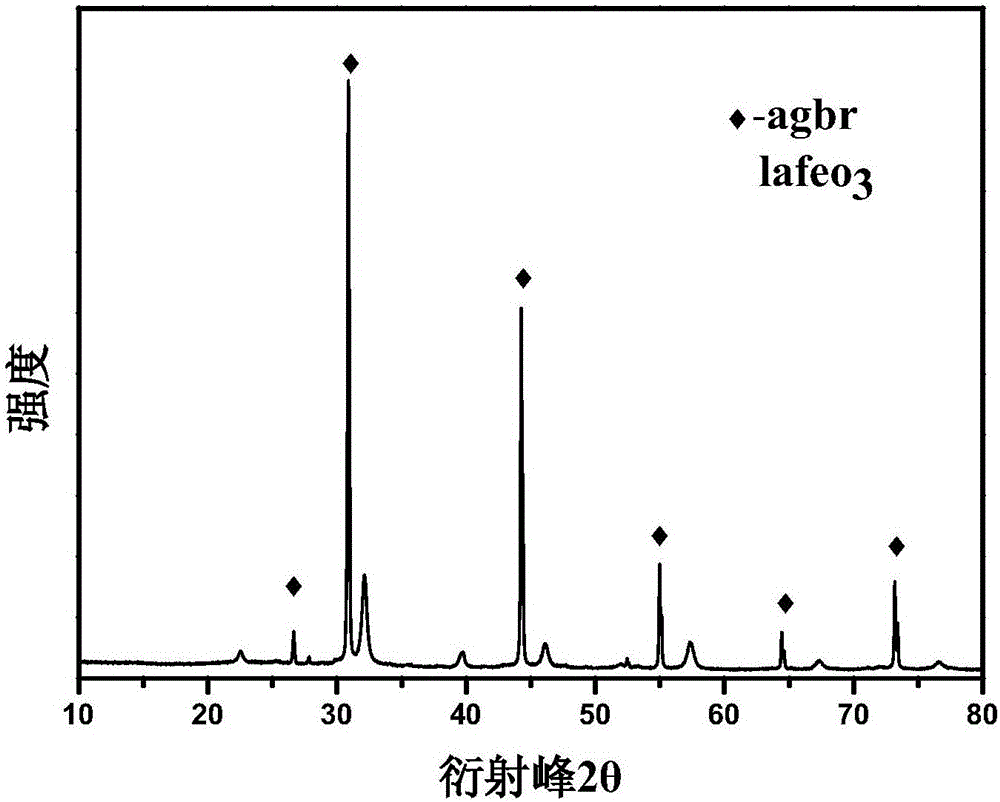

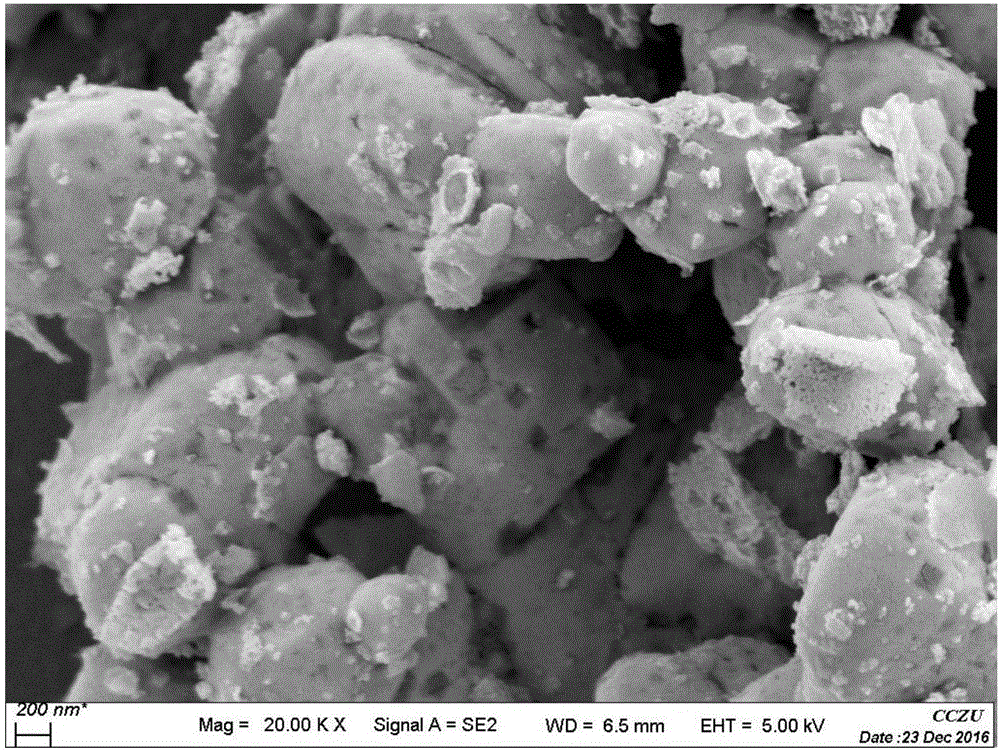

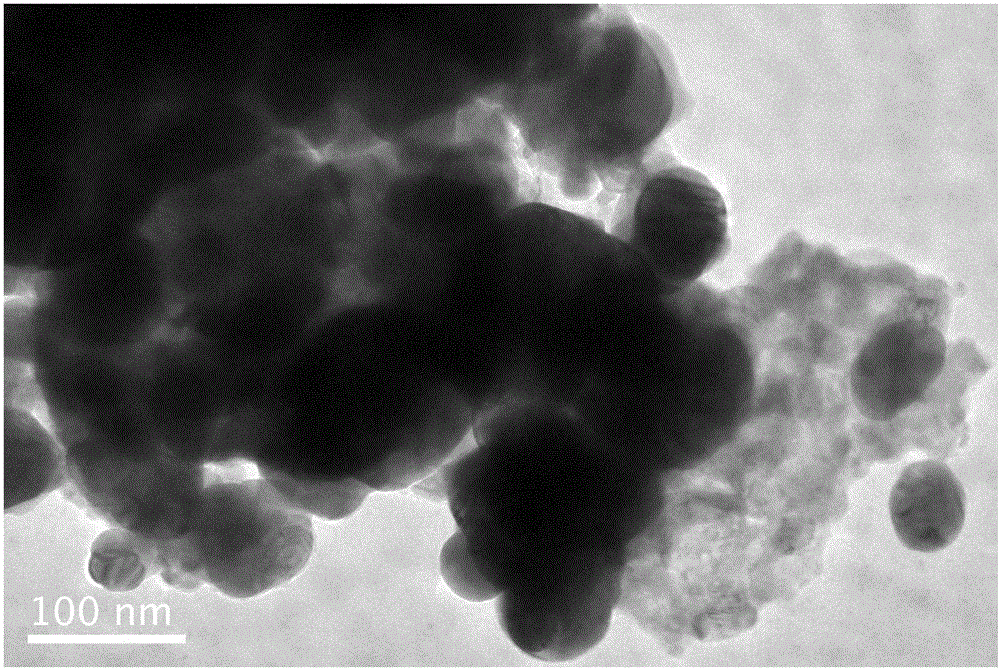

[0027] The crystalline phase structure of the lanthanum ferrite / silver bromide composite photocatalyst prepared in Example 1 is analyzed by a Japan Rigaku D / max2500PC rotation X-ray diffractometer, wherein the X-ray is Cu target Kα The voltage is 40kV, the current is 100mA, the step size is 0.02°, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com