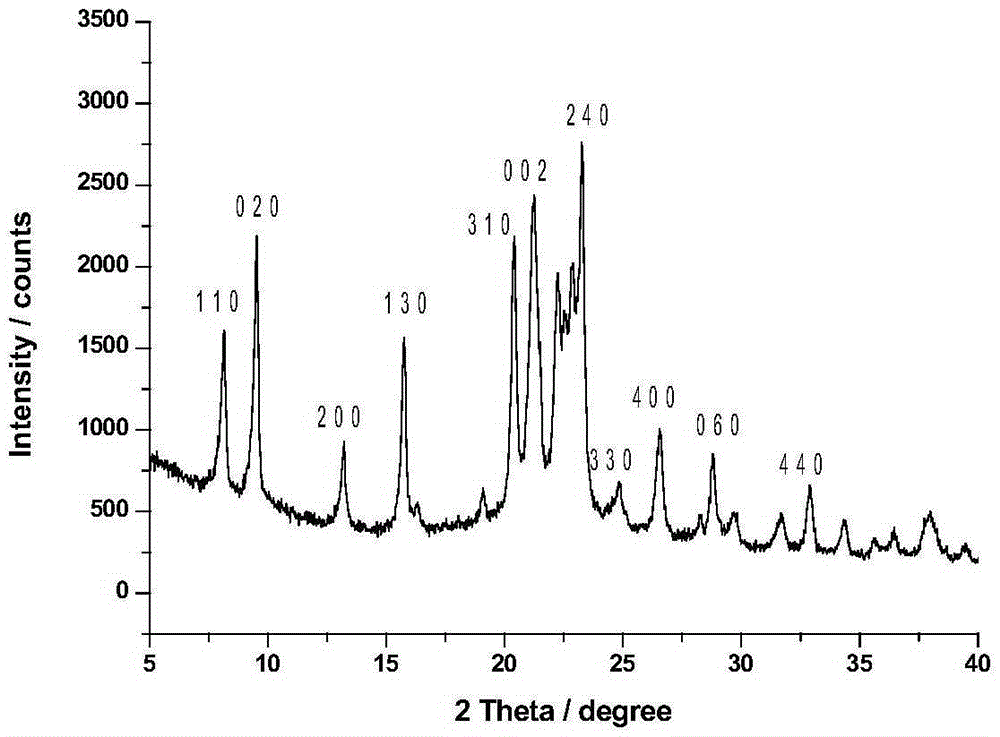

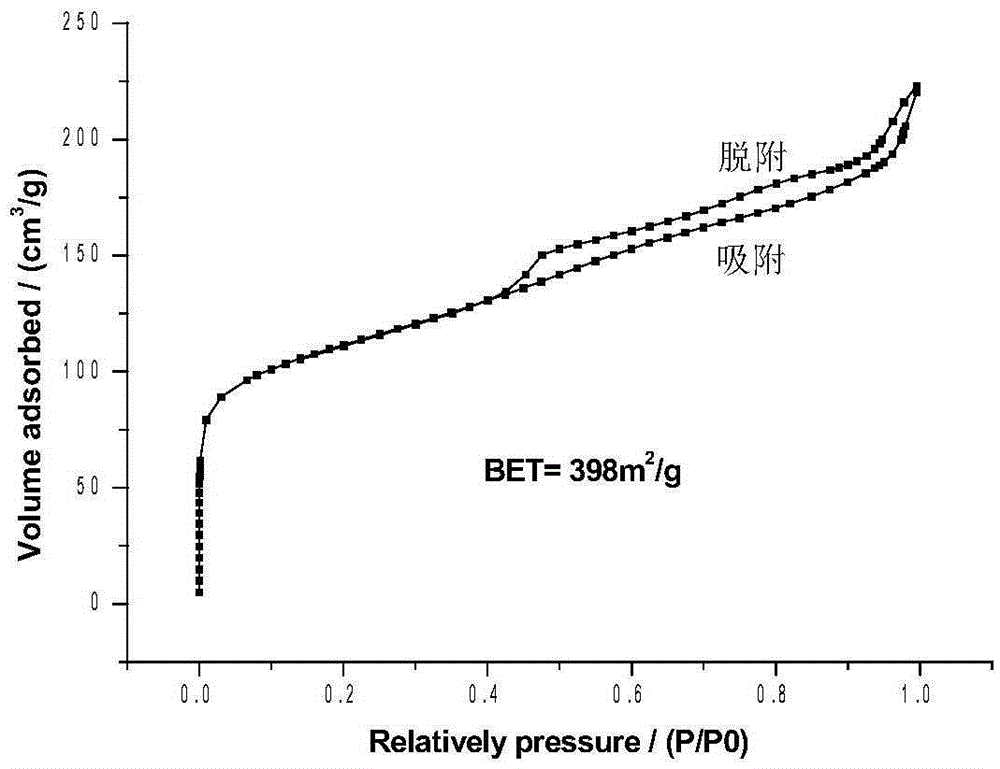

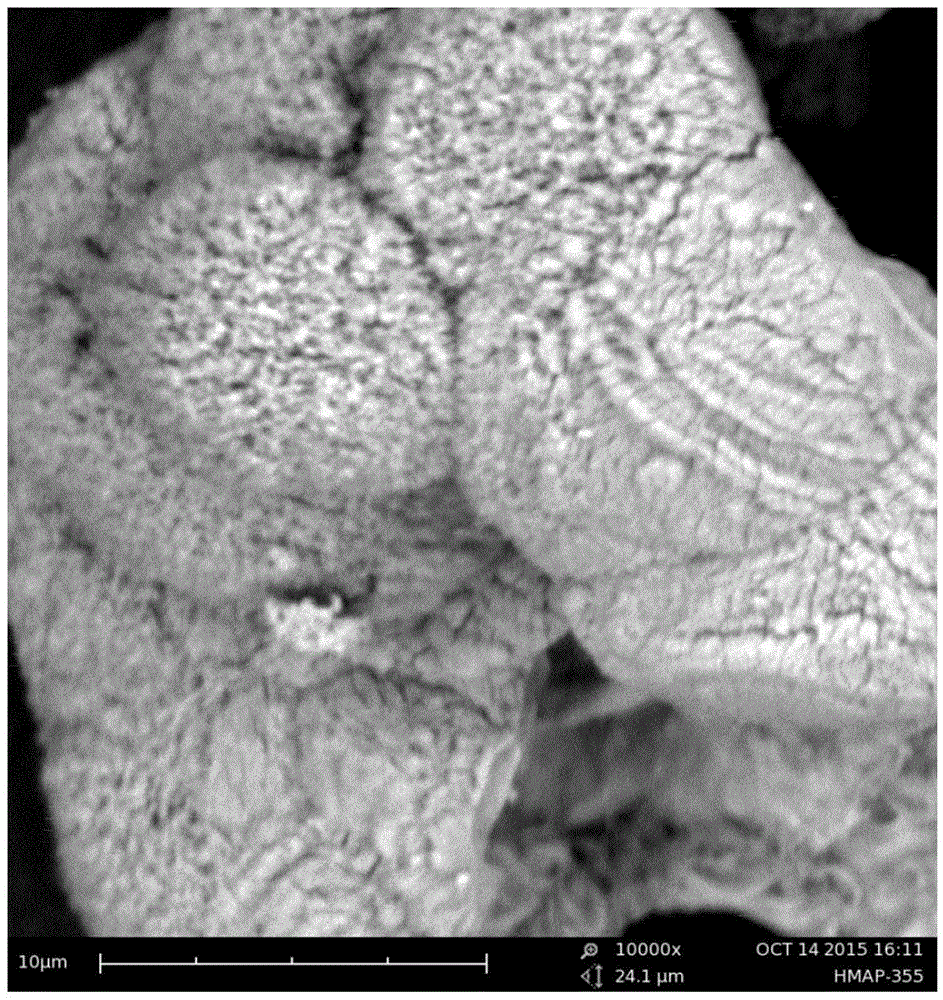

Preparation method for SAPO-11 molecular sieve with large specific surface area and molecular sieve thereof

A technology of SAPO-11 and large specific surface area, which is applied in the field of synthesis of large specific surface area SAPO-11 molecular sieves, can solve the problems of small specific surface area and limit application, and achieve the effects of simple operation, high yield and overcoming low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029]Add 10 g of water to a 50 ml beaker, add 2.0 g of crystalline aluminum chloride under magnetic stirring, evenly add 1.5 g of phosphoric acid with a mass concentration of 85%, stir evenly, add dropwise 0.3 g of tetraethyl orthosilicate, and stir for 30 minutes , add 0.10g dimethyl hexadecyl [3-(trimethoxysilyl) propyl] ammonium chloride, stir well, then add 2 ml of propylene oxide dropwise, and continue to stir for 5 minutes. The mixture was aged at 40° C. for 24 hours, and then dried at 100° C. to obtain a precursor mixture. Take 1 gram of the above-mentioned precursor mixture and place it in a PTFE tray with a bracket, place the tray in a stainless steel reaction kettle, add 1 gram of water and 0.5 gram of n-dipropylamine to the bottom of the reaction kettle, heat up to 200 °C after sealing, and keep After 2 days, the reaction mixture was cooled to room temperature and washed 3 times with deionized water. The final white powder was dried in an oven at 120°C, and tested...

Embodiment 2

[0031] Add 5 g of water and 5 g of ethanol into a 50 ml beaker, add 2.0 g of crystalline aluminum chloride under magnetic stirring, evenly add 1.5 g of phosphoric acid with a mass concentration of 85%, and add dropwise 0.5 g of tetraethyl orthosilicate after stirring evenly. After stirring for 30 minutes, 0.30 g of dimethylhexadecyl[3-(trimethoxysilyl)propyl]ammonium chloride was added, and then 2 ml of propylene oxide was added dropwise, and stirring was continued for 5 minutes. The mixture was aged at 40° C. for 24 hours, and then dried at 100° C. to obtain a precursor mixture. Take 1 gram of the above precursor mixture and place it in a PTFE tray with a bracket, and place the tray in a stainless steel reaction kettle, add 1 gram of water and 1 gram of n-dipropylamine to the bottom of the reaction kettle, heat up to 200 ° C after sealing, and keep After 2 days, the reaction mixture was cooled to room temperature and washed 3 times with deionized water. The final white powde...

Embodiment 3

[0033] Add 10 g of ethanol to a 50 ml beaker, add 2.0 g of crystalline aluminum chloride under magnetic stirring, evenly add dropwise 1.5 g of phosphoric acid with a mass concentration of 85%, stir evenly, add dropwise 0.4 g of tetraethyl orthosilicate, and stir for 30 minutes. 0.30 g of dimethyltetradecyl[3-(trimethoxysilyl)propyl]ammonium chloride was added, followed by 3 ml of propylene oxide dropwise, and stirring was continued for 5 minutes. The mixture was aged at 40° C. for 24 hours, and then dried at 100° C. to obtain a precursor mixture. Take 1 gram of the above-mentioned precursor mixture and place it in a PTFE tray with a bracket, place the tray in a stainless steel reaction kettle, add 1 gram of water and 0.5 gram of n-dipropylamine to the bottom of the reaction kettle, heat up to 200 °C after sealing, and keep After 2 days, the reaction mixture was cooled to room temperature and washed 3 times with deionized water. The final white powder was dried in an oven at 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com