Cathode material NiCo2S4 nano hexagonal piece for lithium ion battery and preparation method thereof

A kind of technology of lithium ion battery and negative electrode material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

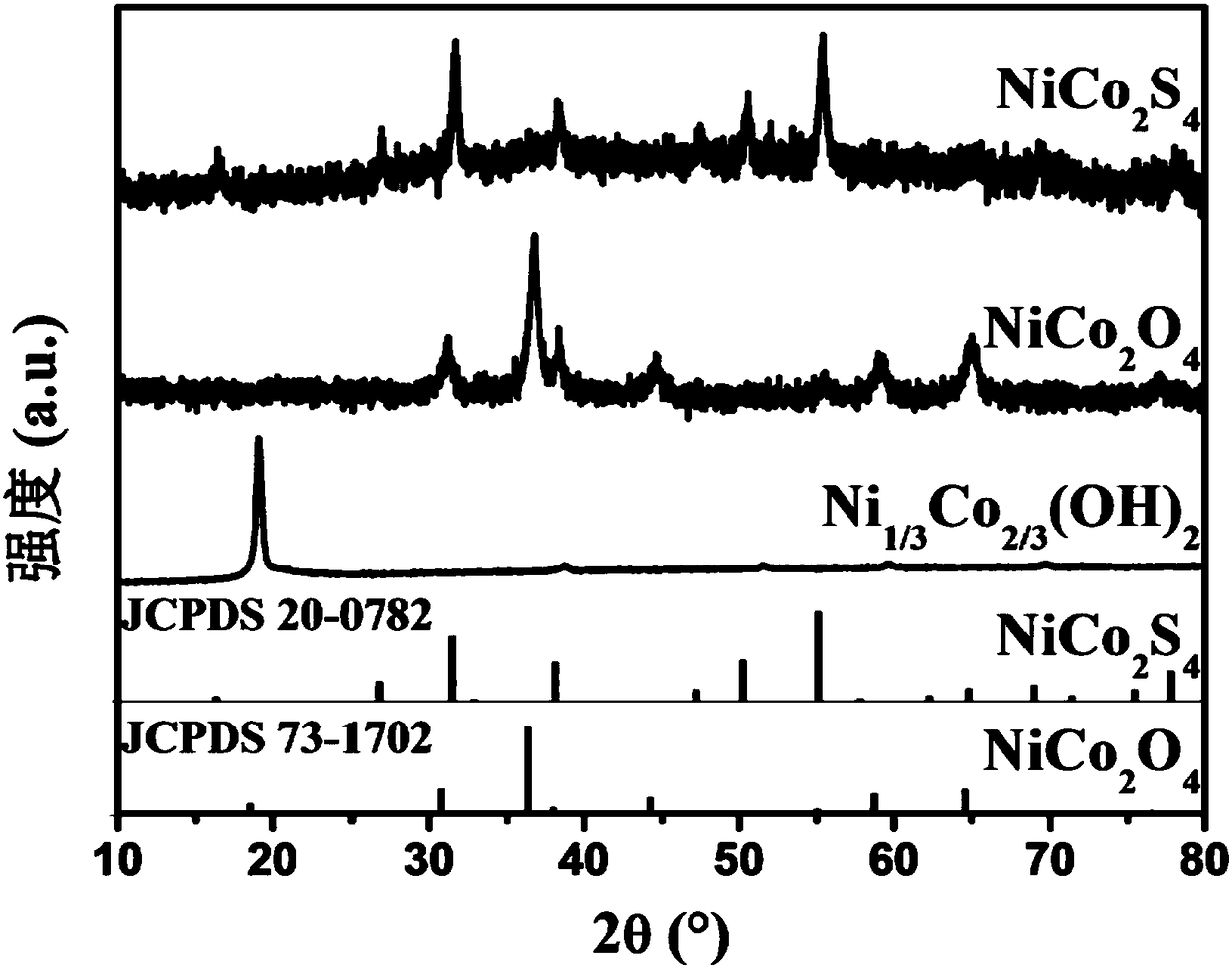

[0040] (1) Synthesis of Ni by hydrothermal co-precipitation method 1 / 3 co 2 / 3 (OH) 2 Nano hexagonal sheet:

[0041] 2.5mmolNiCl 2 ∙6H 2 O, 5 mmol CoCl 2 ∙6H 2 O and 45mmol hexamethylenetetramine were dispersed in 1000mL deoxygenated deionized water, and in N 2 In the protection of gas, the magnetic stirring reaction was carried out at 120°C for 5h. After centrifugation, washing with water, and alcohol washing, it was dried in an oven at 60°C to obtain light pink Ni 1 / 3 co 2 / 3 (OH) 2 .

[0042] (2) Anneal to get NiCo 2 o 4 Nano hexagonal sheet:

[0043] 100mg Ni after drying 1 / 3 co 2 / 3 (OH) 2 Put the hexagonal flake powder sample into a quartz crucible. As for the tube furnace, heat it to 500°C in the air at a heating rate of 1°C / min, keep it at this temperature for 2h, and cool it down to room temperature naturally to obtain NiCo 2 o 4 Nano hexagonal sheet.

[0044] (3) Sulfurization to obtain NiCo 2 S 4 Nano hexagonal sheet.

[0045] 100mg NiCo 2 o 4 Pu...

Embodiment 2

[0049] (1) Synthesis of Ni by hydrothermal co-precipitation method 1 / 3 co 2 / 3 (OH) 2 Nano hexagonal sheet:

[0050] 3mmolNiCl 2 ∙6H 2 O, 6 mmol CoCl 2 ∙6H 2 O and 54mmol hexamethylenetetramine were dispersed into 1200mL deoxygenated deionized water, and in N 2 In the protection of gas, the magnetic stirring reaction was carried out at 120°C for 6h. After centrifugation, washing with water, and alcohol washing, it was dried in an oven at 70°C to obtain light pink Ni 1 / 3 co 2 / 3 (OH) 2 .

[0051] (2) Anneal to get NiCo 2 o 4 Nano hexagonal sheet:

[0052] 200mg Ni after drying 1 / 3 co 2 / 3 (OH) 2 Put the hexagonal flake powder sample into a quartz crucible, and heat it to 600°C in the air at a heating rate of 3°C / min in a tube furnace, keep it at this temperature for 6h, and cool it down to room temperature naturally to obtain NiCo 2 o 4 Nano hexagonal sheet.

[0053] (3) Sulfurization to obtain NiCo 2 S 4 Nano hexagonal sheet.

[0054] 200mg NiCo 2 o 4 Put t...

Embodiment 3

[0058] (1) Synthesis of Ni by hydrothermal co-precipitation method 1 / 3 co 2 / 3 (OH) 2 Nano hexagonal sheet:

[0059] 2mmolNiCl 2 ∙6H 2 O, 4 mmol CoCl 2 ∙6H 2 O and 36mmol of hexamethylenetetramine were dispersed in 800mL deoxygenated deionized water, and the 2 In the protection of gas, the magnetic stirring reaction was carried out at 110°C for 4 hours. After centrifugation, washing with water, and alcohol washing, it was dried in an oven at 60°C to obtain light pink Ni 1 / 3 co 2 / 3 (OH) 2 .

[0060] (2) Anneal to get NiCo 2 o 4 Nano hexagonal sheet:

[0061] 50mg Ni after drying 1 / 3 co 2 / 3 (OH) 2 Put the hexagonal flake powder sample into a quartz crucible, and in a tube furnace, heat it to 400°C in air at a heating rate of 2°C / min, keep it at this temperature for 4h, and cool it down to room temperature naturally to obtain NiCo 2 o 4 Nano hexagonal sheet.

[0062] (3) Sulfurization to obtain NiCo 2 S 4 Nano hexagonal sheet.

[0063] 50mg NiCo 2 o 4 Put th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com