Equipment for preparing high-purity zinc phosphate through mechanical activation and continuous reaction and application thereof

A high-purity zinc phosphate, mechanical activation technology, applied in inorganic chemistry, phosphorus compounds, chemical instruments and methods, etc., can solve the problems of packaging, product quality is not easy to control, low yield, etc., to reduce reaction time, widely popularized and applied Promising, high-yield effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

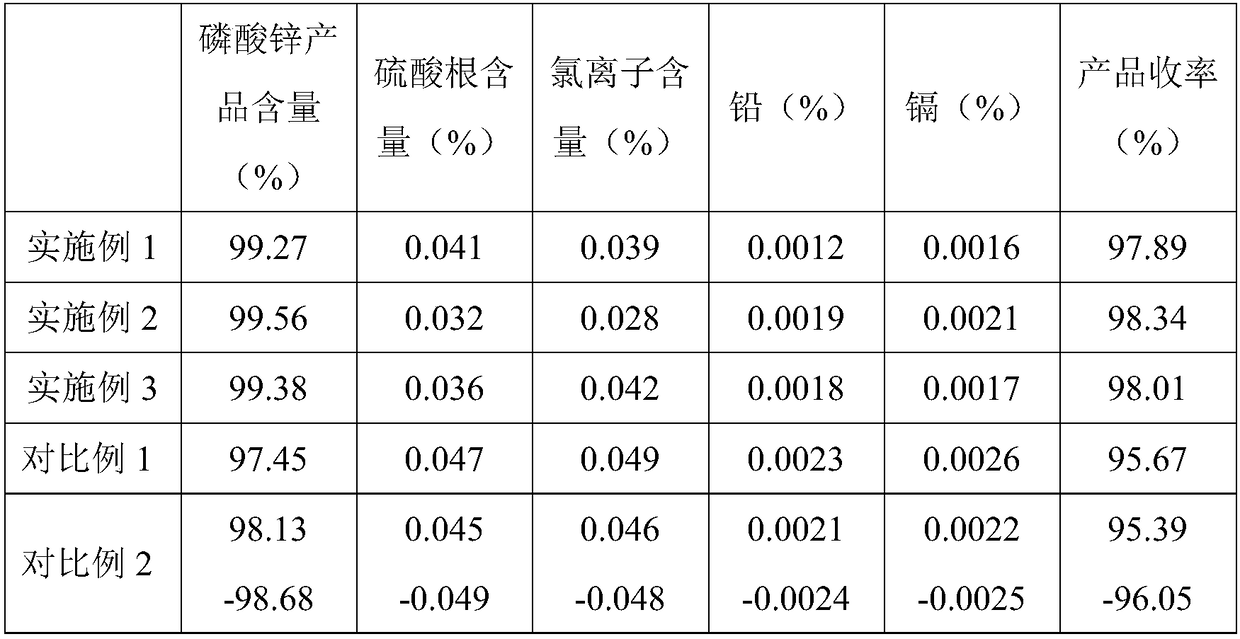

Embodiment 1

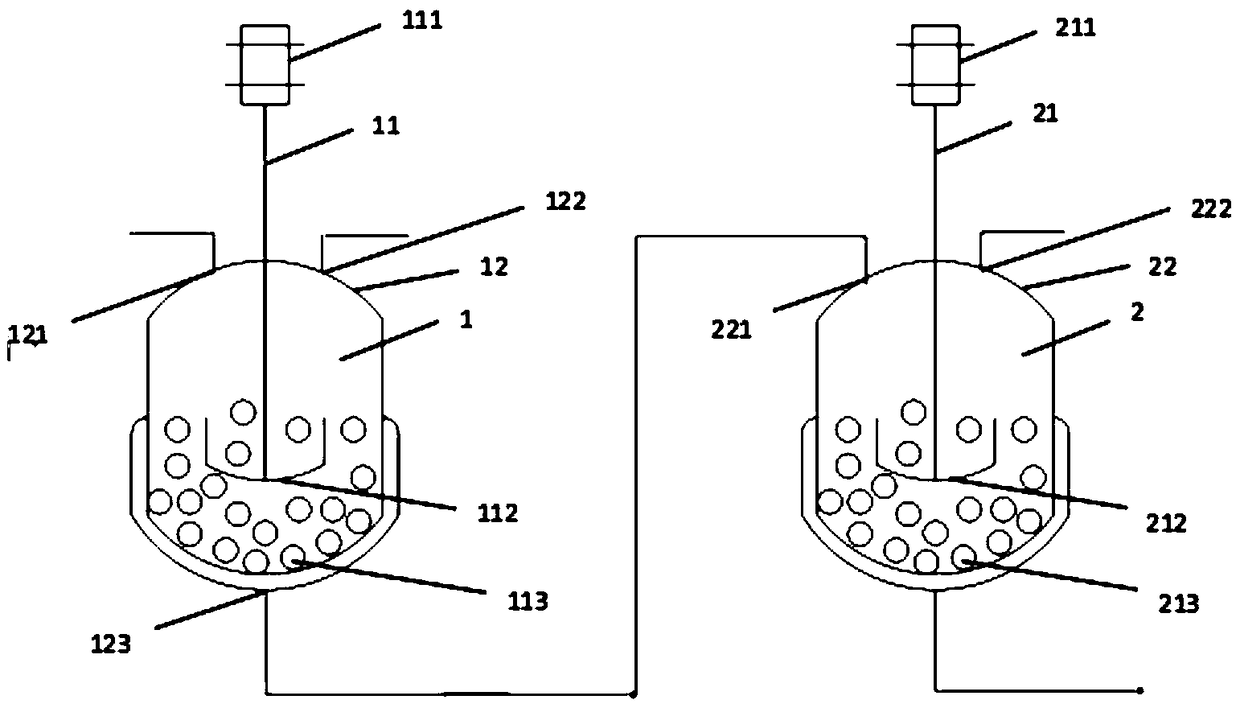

[0027] A kind of equipment for preparing high-purity zinc phosphate by continuous reaction of mechanical activation, comprising a first reaction kettle and a second reaction kettle, the first reaction kettle and the second reaction kettle are connected by pipelines, specifically applied to the preparation of high-purity zinc phosphate including the following step:

[0028] S1: Dissolve soluble ammonium carbonate and soluble zinc sulfate in water respectively, and prepare ammonium carbonate solution and zinc sulfate solution according to the molar ratio of carbonate ions to zinc ions per unit volume of 1:1;

[0029] S2: Transport the zinc sulfate solution to the first reaction kettle at one time, then continuously add the ammonium carbonate solution, stop feeding after adding the same volume of ammonium carbonate solution, and make the two solutions synergistically wet in the first reaction kettle at 25°C Method of mechanical activation, reaction made zinc carbonate or basic zi...

Embodiment 2

[0032] A kind of equipment for preparing high-purity zinc phosphate by continuous reaction of mechanical activation, comprising a first reaction kettle and a second reaction kettle, the first reaction kettle and the second reaction kettle are connected by pipelines, specifically applied to the preparation of high-purity zinc phosphate including the following step:

[0033] S1: Dissolve soluble sodium bicarbonate and soluble zinc nitrate in water respectively, and prepare sodium bicarbonate solution and zinc nitrate solution according to the molar ratio of carbonate ion to zinc ion per unit volume of 1.5:1;

[0034] S2: Transport the zinc sulfate solution to the first reaction kettle at one time, then continuously add the ammonium carbonate solution, stop feeding after adding the same volume of ammonium carbonate solution, and make the two solutions synergistically wet in the first reaction kettle at 50°C Method mechanical activation, carry out reaction and make zinc carbonate ...

Embodiment 3

[0037] A kind of equipment for preparing high-purity zinc phosphate by continuous reaction of mechanical activation, comprising a first reaction kettle and a second reaction kettle, the first reaction kettle and the second reaction kettle are connected by pipelines, specifically applied to the preparation of high-purity zinc phosphate including the following step:

[0038] S1: Dissolve soluble potassium carbonate and soluble zinc chlorate in water respectively, and prepare potassium carbonate solution and zinc salt solution according to the molar ratio of carbonate ions to zinc ions per unit volume of 2:1;

[0039] S2: Transport the zinc chlorate solution to the reaction kettle once, then continuously add the potassium carbonate solution, stop feeding after adding the same volume of potassium carbonate solution, and make the two solutions cooperate with the wet method in the first reaction kettle at 80°C Mechanical activation, reacting to obtain zinc carbonate or basic zinc ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com