Fiber reinforced silicate fireproof board produced by doping industrial waste residue and preparation method and application thereof

A fiber-reinforced, industrial waste slag technology, applied in the field of silicate fireproof boards, can solve the problems of polished brick waste slag with many impurities, difficult product quality assurance, and high overall density, achieving remarkable environmental protection, good high-temperature dimensional stability, and production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

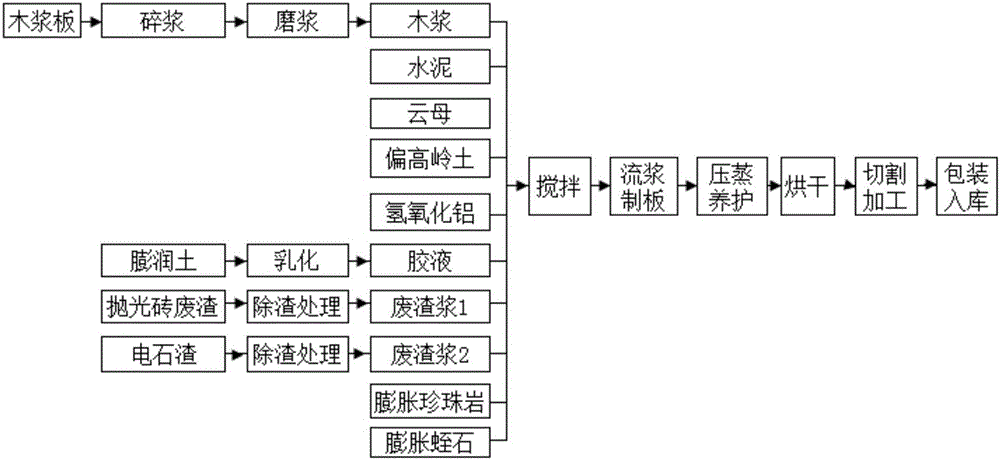

[0065] A preparation of fiber-reinforced silicate fire-proof board produced by mixing industrial waste residues, which is manufactured by the slurry method, such as figure 1 shown, including the following steps:

[0066] 1) Pulping and refining the wood pulp board into wood pulp for later use, emulsifying the bentonite with a concentration of 10% in an emulsifier for 1 hour for later use, and removing the polished brick waste slag and calcium carbide slag;

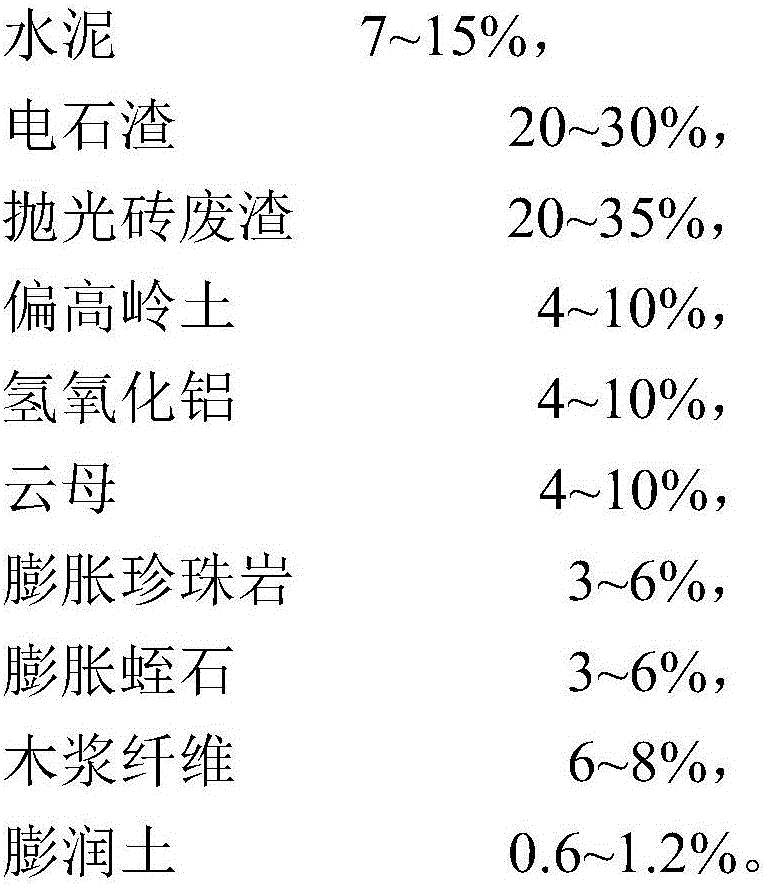

[0067] 2) After mixing the treated materials according to the following proportions, add water to stir and control the concentration to 15%;

[0068]

[0069] 3) Flowing the material obtained in step 2), that is, forming a thin material layer of 1.0 mm through flow slurry, and then stacking each thin material layer through a forming cylinder to form a slab of 9 mm;

[0070] 4) The slab obtained in step 3) is subjected to hot-pressurization with saturated steam at a pressure of 1 MPa for 10 hours to form a strong plate,...

Embodiment 2

[0072] A preparation of a fiber-reinforced silicate fireproof board produced by mixing industrial waste slag, the steps are the same as in Example 1, except that:

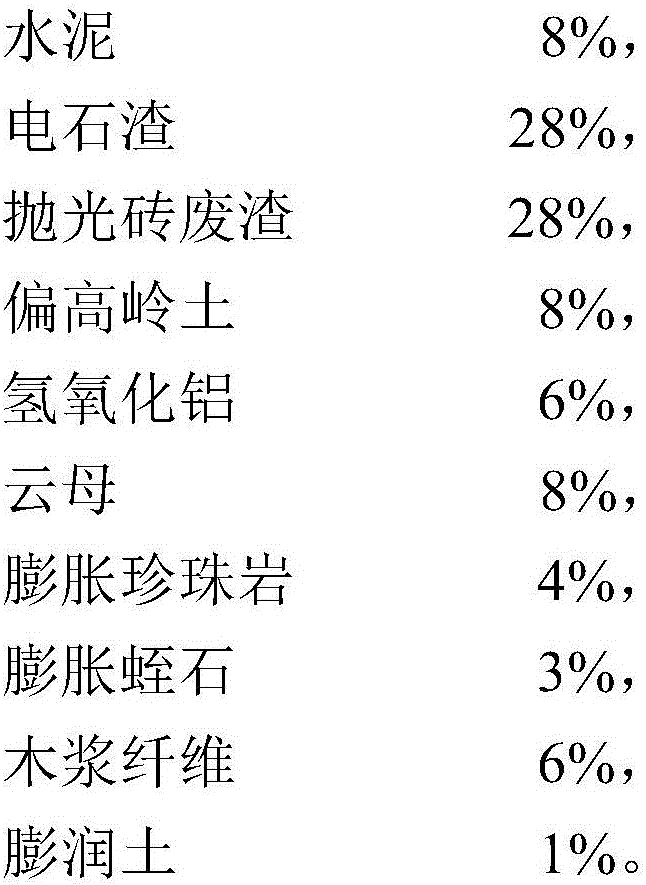

[0073] Concentration in step 2) is 20%; Raw material mass percent is:

[0074]

[0075]

[0076] In step 3), the thin material layer thickness is 1.5mm, and the thickness of the slab is 13.5mm;

Embodiment 3

[0078] A preparation of a fiber-reinforced silicate fireproof board produced by mixing industrial waste slag, the steps are the same as in Example 1, except that:

[0079] Concentration in step 2) is 18%; Raw material mass percent is:

[0080]

[0081] In step 3), the thickness of the thin material layer is 1.2mm, and the thickness of the slab is 10.8mm;

PUM

| Property | Measurement | Unit |

|---|---|---|

| power level | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com