Device and method for producing sulfur-containing phosphate fertilizer by adding liquid sulfur into gas phase

A gas phase, liquid sulfur technology, applied in phosphate fertilizers, ammonium orthophosphate fertilizers, alkaline orthophosphate fertilizers, etc., can solve the problems of reduced ammonium phosphate pelleting rate, large dust, and many returned materials, and achieves the control of dust pollution, The effect of high ball forming rate and less material return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

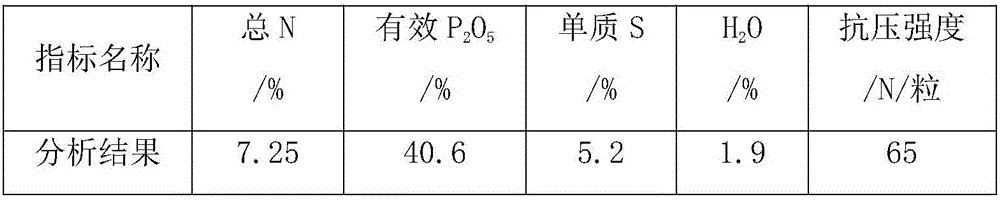

Embodiment 1

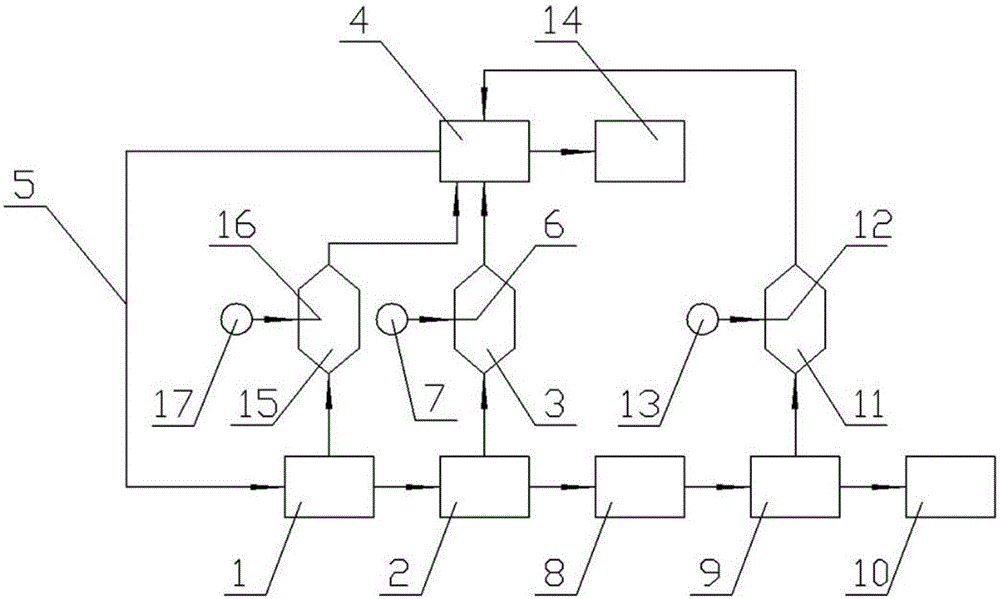

[0052] The air outlet of the above-mentioned dryer 2 is connected with the air inlet of the first gas-phase chamber 3, the air outlet of the above-mentioned first gas-phase chamber 3 is connected with the air inlet of the cyclone separator 4, and the material outlet of the above-mentioned cyclone separator 4 is connected with the above-mentioned manufacturing The granulator 1 is connected by a return belt 5; the first gas phase chamber 3 is provided with a first liquid sulfur nozzle 6, and the first liquid sulfur nozzle 6 is connected with a first flow meter 7.

[0053] Steps include:

[0054] S1. After the phosphate fertilizer is transported to the above-mentioned granulator 1 for granulation, it is then transported to the above-mentioned dryer 2 for drying, and the above-mentioned dryer 2 blows the gas phase containing the phosphate fertilizer dust to the above-mentioned first gas phase chamber 3;

[0055] S2. Feed liquid sulfur into the first liquid sulfur nozzle 6, adjust ...

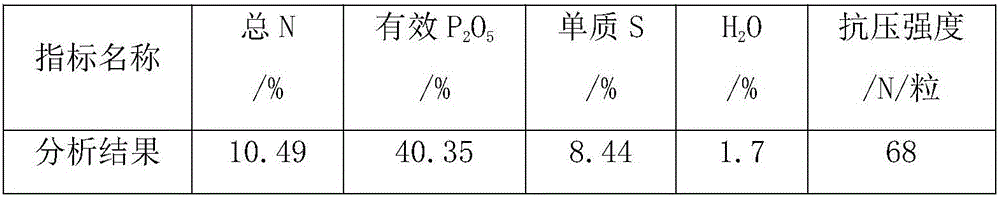

Embodiment 2

[0059] The air outlet of the above-mentioned dryer 2 is connected with the air inlet of the first gas-phase chamber 3, the air outlet of the above-mentioned first gas-phase chamber 3 is connected with the air inlet of the cyclone separator 4, and the material outlet of the above-mentioned cyclone separator 4 is connected with the above-mentioned manufacturing The granulator 1 is connected by a return belt 5; the first gas phase chamber 3 is provided with a first liquid sulfur nozzle 6, and the first liquid sulfur nozzle 6 is connected with a first flow meter 7.

[0060] The gas outlet of above-mentioned fluidized bed 9 is connected with the inlet of second gas phase chamber 11, and the gas outlet of above-mentioned second gas phase chamber 11 is connected with the inlet of above-mentioned cyclone separator 4; The second liquid sulfur spray head 12 , the second liquid sulfur spray head 12 is connected to the second flow meter 13 .

[0061] Steps include:

[0062] S1. After the...

Embodiment 3

[0070] The air outlet of the above-mentioned dryer 2 is connected with the air inlet of the first gas-phase chamber 3, the air outlet of the above-mentioned first gas-phase chamber 3 is connected with the air inlet of the cyclone separator 4, and the material outlet of the above-mentioned cyclone separator 4 is connected with the above-mentioned manufacturing The granulator 1 is connected by a return belt 5; the first gas phase chamber 3 is provided with a first liquid sulfur nozzle 6, and the first liquid sulfur nozzle 6 is connected with a first flow meter 7.

[0071] The gas outlet of above-mentioned fluidized bed 9 is connected with the inlet of second gas phase chamber 11, and the gas outlet of above-mentioned second gas phase chamber 11 is connected with the inlet of above-mentioned cyclone separator 4; The second liquid sulfur spray head 12 , the second liquid sulfur spray head 12 is connected to the second flow meter 13 .

[0072] The air outlet of the above-mentioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com