Method for producing selenium-enriched konjak by using selenium-enriched pelleted seed konjak

A kind of taro planting and coating technology, which is applied in the direction of seed coating/seed dressing, botany equipment and methods, application, etc., can solve the problem of unstable selenium content in selenium-enriched konjac, achieve no geographical restrictions, facilitate scale, The effect of controllable selenium content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: a kind of method that uses selenium-enriched coated seed taro to produce selenium-enriched konjac comprises the following steps:

[0029] a.

[0030] Preparation of soaking solution: Weigh 3g of sodium selenite with a purity of more than 98% and 10g of potassium permanganate in a basin or barrel, add 1L of water first, stir to dissolve, then add 9L of water, stir evenly, and prepare 0.03% selenium Sodium Oxide-0.1% Potassium Permanganate Mixed Soaking Solution;

[0031] b.

[0032] Preparation of sodium selenite coating agent: Weigh 5g-25g of sodium selenite with a purity of more than 98%, and mix it into 50kg of lime-sulfur mixture. The lime-sulfur mixture is: quicklime: fine sulfur powder = 1:1.5, manually or mechanically Stir and mix well to become a seed coating agent, the content of sodium selenite is 100mg / kg-500mg / kg;

[0033] c.

[0034] Seed soaking: soak the dormant taro in the sodium selenite-potassium permanganate soaking solution for 3h-5h...

Embodiment 2

[0039] Embodiment 2: A kind of method that uses selenium-enriched coated seed taro to produce selenium-enriched konjac, the selenium-enriched effect of planting konjac with selenium-enriched nutrition block

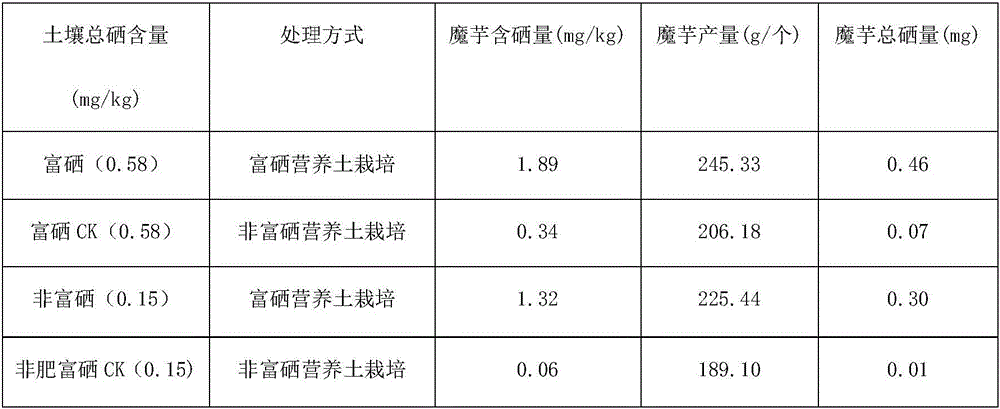

[0040] After konjac is soaked in 0.1% potassium permanganate-0.03% sodium selenite solution for 2h-3h, it is coated with lime sulfur mixture with a sodium selenite content of 400mg / kg, and transplanted to the experimental field. Seed soaking and non-coating cultivation were used as controls. After the seedlings were poured, 10 were weighed respectively to measure the selenium content. The results are shown in the following table:

[0041] Table 1 The selenium-enriching effect of cultivating konjac in different soils using selenium-enriched nutrient blocks

[0042]

[0043] As can be seen from the table, the use of selenium solution soaking + selenium-enriched coating seed taro cultivation can greatly increase the selenium content of konjac. The selenium content of konj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com