Compound type water body bactericide and preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

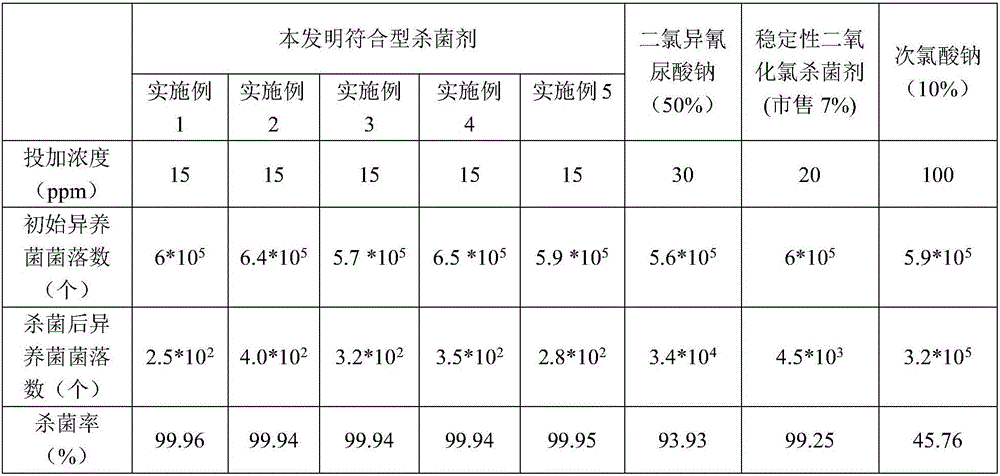

Examples

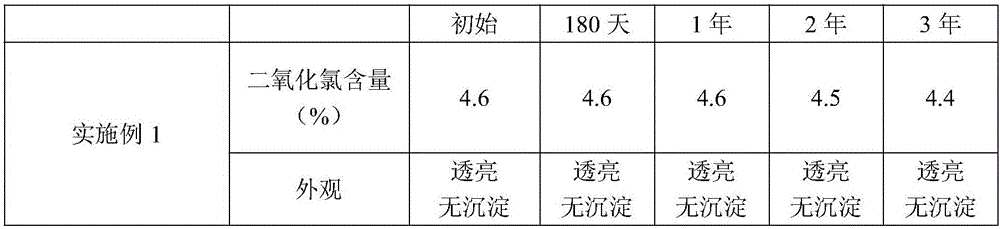

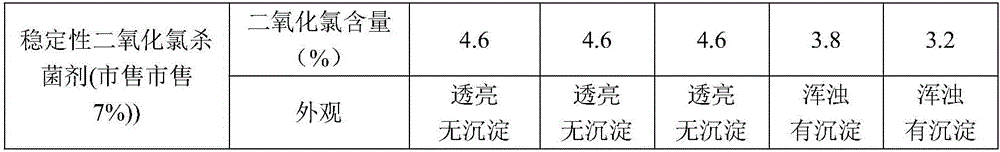

Embodiment 1

[0028] A composite water body bactericide, comprising the following components in parts by weight: 20 parts of 31% sodium chlorite aqueous solution, 2.5 parts of 1% borax, 3 parts of 2% hydrogen peroxide, 1 part of sodium peroxide, and 1 part of magnesium peroxide , 0.7 parts of pentasodium diethylenetriamine pentaacetate, 0.8 parts of tetrasodium hydroxyethylenediamine tetraacetate, 1 part of disodium hydrogen phosphate, 1 part of sodium dihydrogen phosphate and 69 parts of distilled water.

[0029] The preparation method is as follows:

[0030] S1: First add half of the distilled water to the reaction kettle, add 31% sodium chlorite aqueous solution into the reaction kettle, and fully stir for 25 minutes;

[0031] S2: Add 2% hydrogen peroxide to the above reaction kettle, and stir for 20 minutes;

[0032] S3: Add 1% borax to the above reaction kettle, and stir for 15 minutes;

[0033] S4: Add sodium peroxide and magnesium peroxide to the above reaction kettle, and fully st...

Embodiment 2

[0039] A composite water body bactericide, comprising the following components in parts by weight: 15 parts of 31% sodium chlorite aqueous solution, 2 parts of 1% borax, 2 parts of 2% hydrogen peroxide, 0.5 parts of sodium peroxide, and 0.5 parts of magnesium peroxide , 0.5 parts of pentasodium diethylenetriamine pentaacetate, 0.5 parts of tetrasodium hydroxyethylenediamine tetraacetate, 0.5 parts of disodium hydrogen phosphate, 0.5 parts of sodium dihydrogen phosphate and 78 parts of distilled water.

[0040] The preparation method is as follows:

[0041] S1: First add half of the distilled water to the reaction kettle, add 31% sodium chlorite aqueous solution into the reaction kettle, and fully stir for 15 minutes;

[0042] S2: Add 2% hydrogen peroxide to the above reaction kettle, and stir for 15 minutes;

[0043] S3: Add 1% borax to the above reaction kettle, and stir for 10 minutes;

[0044] S4: Add sodium peroxide and magnesium peroxide to the above reaction kettle, an...

Embodiment 3

[0050] A composite water body bactericide, which consists of the following components in parts by weight: 18 parts of 31% sodium chlorite aqueous solution, 2.3 parts of 1% borax, 2.5 parts of 2% hydrogen peroxide, 0.7 parts of sodium peroxide, and 0.7 parts of magnesium peroxide , 0.6 parts of pentasodium diethylenetriamine pentaacetate, 0.6 parts of tetrasodium hydroxyethylenediamine tetraacetate, 0.8 parts of disodium hydrogen phosphate, 0.8 parts of sodium dihydrogen phosphate and 73 parts of distilled water.

[0051] The preparation method is as follows:

[0052] S1: First add half of the distilled water to the reaction kettle, add 31% sodium chlorite aqueous solution into the reaction kettle, and fully stir for 20 minutes;

[0053] S2: Add 2% hydrogen peroxide to the above reactor, and stir for 17 minutes;

[0054] S3: Add 1% borax to the above reaction kettle, and stir for 13 minutes;

[0055] S4: Add sodium peroxide and magnesium peroxide to the above reaction kettle,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com