A kind of natural compound sweetener and preparation method thereof

A compound sweetener and natural technology, applied in separation methods, chemical instruments and methods, solvent extraction, etc., can solve the problem of difficult to cover up the bad aftertaste of mogroside and neotame, and undisclosed new edible substitute sugar Sweetness and sweetness, product uniformity, poor stability and other issues, to achieve similar sweetness, stable properties, and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

reference example 1

[0039] The preparation process of Mogroside V is as follows: select 100kg of fresh and ripe Luo Han Guo, crush it with a crusher, and then add it to boiling water to extract 4 times, each time the water consumption is 150L, collect 610L of the extract for four times and filter it tightly, and then use 30000D molecular weight Separation by nanofiltration membrane, and then use 10L of anion and cation resin columns to decolorize according to the first yin and then yang. The 23.5kg retentate after decolorization is concentrated to Brix17 under the condition of 25 ℃ and 1.5MPa pressure by reverse osmosis membrane, and then in The frequency is 50Hz, sterilized at 122°C, the sterilized solution is collected, and the paste is collected by vacuum concentration to Brix68. The paste is vacuum-dried at 60°C and -0.095MPa, and finally 0.92kg of dry powder is obtained. The content of mogroside V is 51.0%.

reference example 2

[0041] The preparation process of natural tea theanine is as follows: select 20kg of newly produced spring tea (the content of theanine in dry leaves is 2.3%), crush it to 20-40 mesh, extract it twice with water at room temperature, and use 80L water for the first time Extract for 30 minutes, extract with 60L of water for the second time for 30 minutes, collect twice 138L of extracts and filter them tightly, then separate with 8000D molecular weight nanofiltration membrane, concentrate the retained liquid to Brix32 in vacuum, and then sterilize at a frequency of 50Hz and a temperature of 122°C , the sterilized solution was vacuum-dried at 60°C and -0.095MPa, and finally 1.98kg of dry powder was obtained, and the content of theanine was measured to be 21.4%.

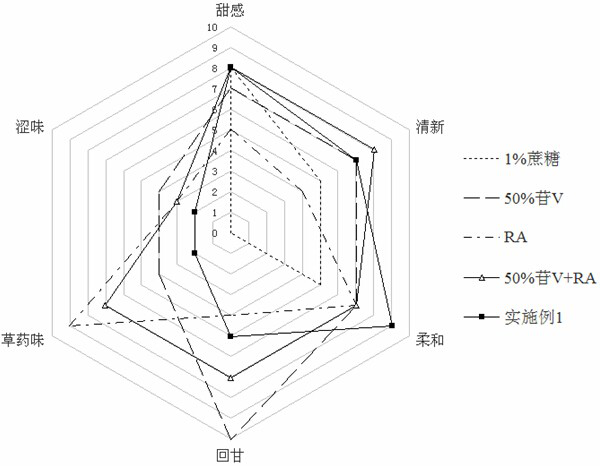

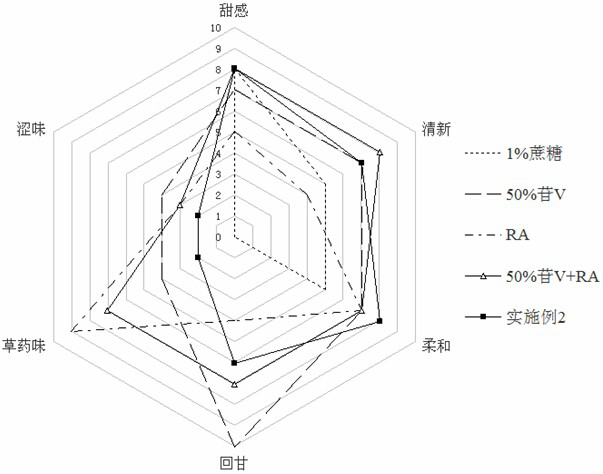

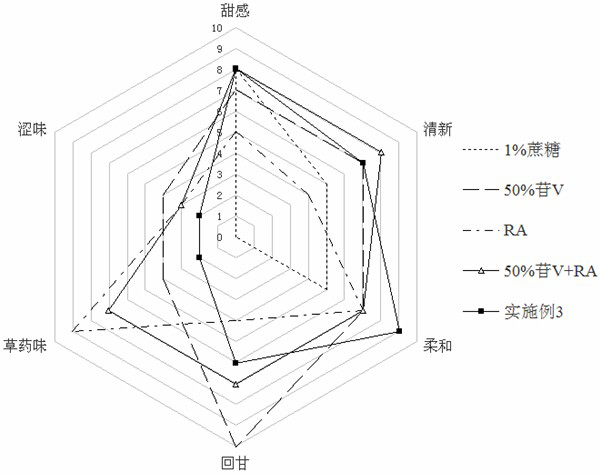

[0042] Natural compound sweetener embodiment 1~3

[0043] The weight parts of each raw material in natural compound sweetener embodiment 1~3, as shown in table 1:

[0044] Table 1 The weight list of each raw material in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com