Fresh processing method for Armeniaca mume Sieb

A processing method and fresh processing technology, which can be used in pharmaceutical formulas, skin care preparations, cosmetics, etc., can solve the problems of low energy consumption, high efficiency, and difficulty in retaining fragrance substances, and achieve low energy consumption, high product quality, and high efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment one: the fresh processing method of white plum blossom

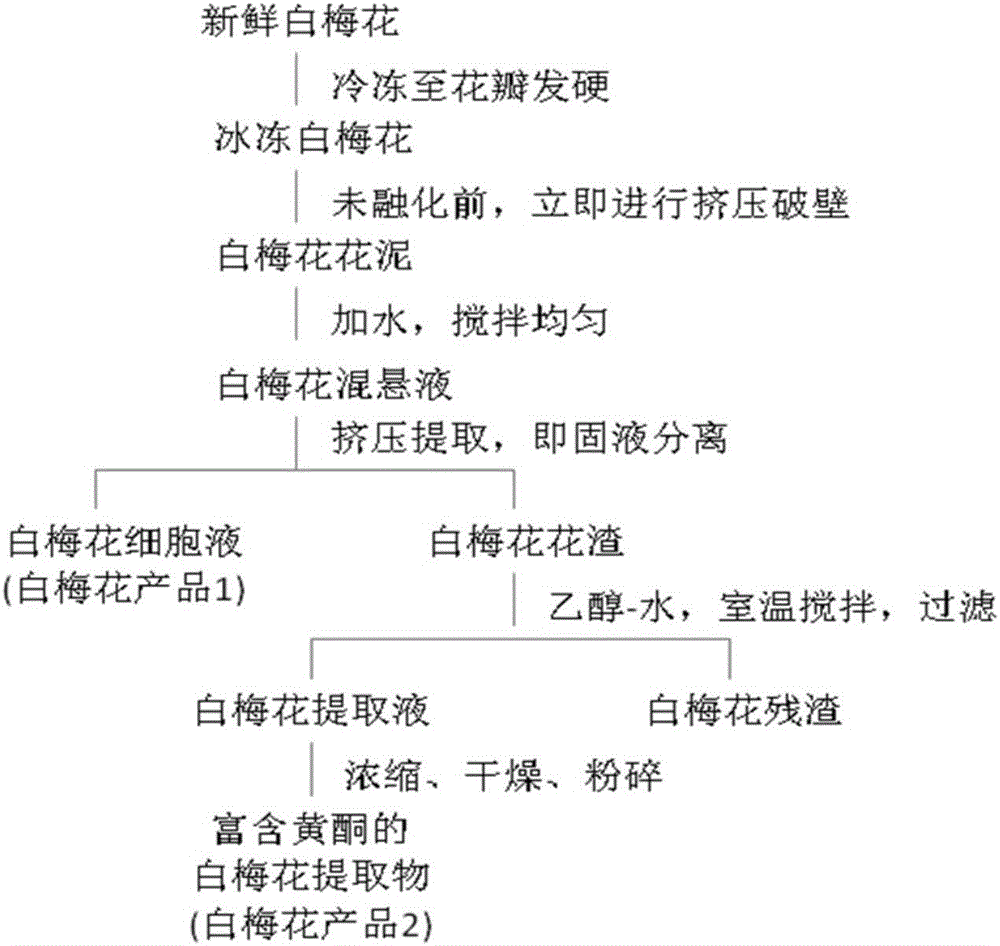

[0047] See attached figure 1 , the invention provides a fresh processing method of plum blossoms, said processing method comprising the steps of:

[0048] (1) Freezing-extruding and breaking the wall: the freshly picked white plum blossoms are frozen into hard frozen white plum blossoms; the hard white plum blossoms in the frozen state are extruded to break the white plum blossom cells.

[0049] (2) Squeeze, extract and separate: Add water to the white plum blossoms with broken cells, stir evenly, squeeze and separate the cell fluid and flower residue, and calculate the cell fluid yield, cell fluid solid content, and chlorogenic acid yield.

[0050] (3) Flower dregs extraction: Add ethanol-water solution as a solvent to the white plum blossom dregs obtained in step (2), stir and extract at room temperature to obtain white plum blossom extract, and calculate the yield of chlorogenic acid and the purity of...

Embodiment 2

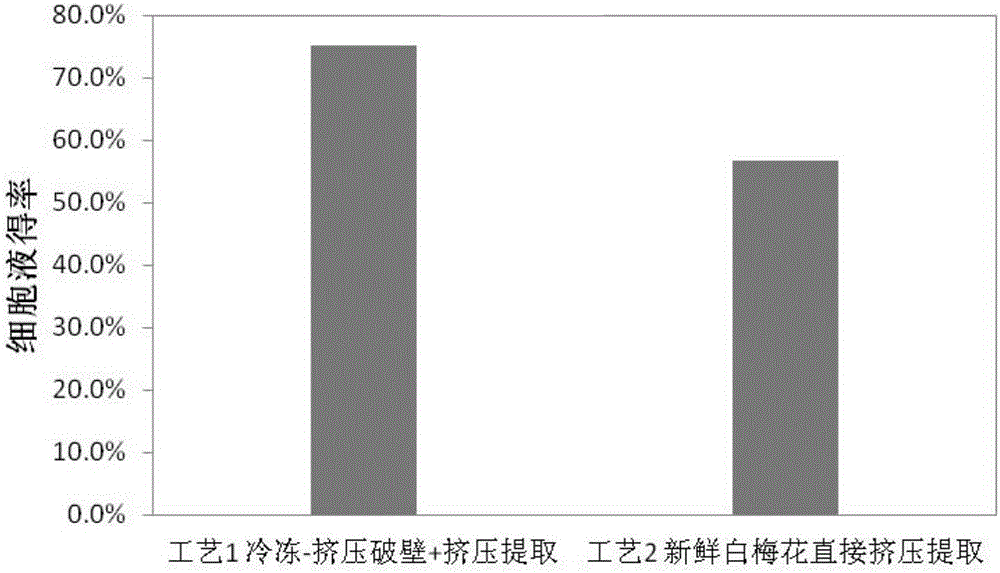

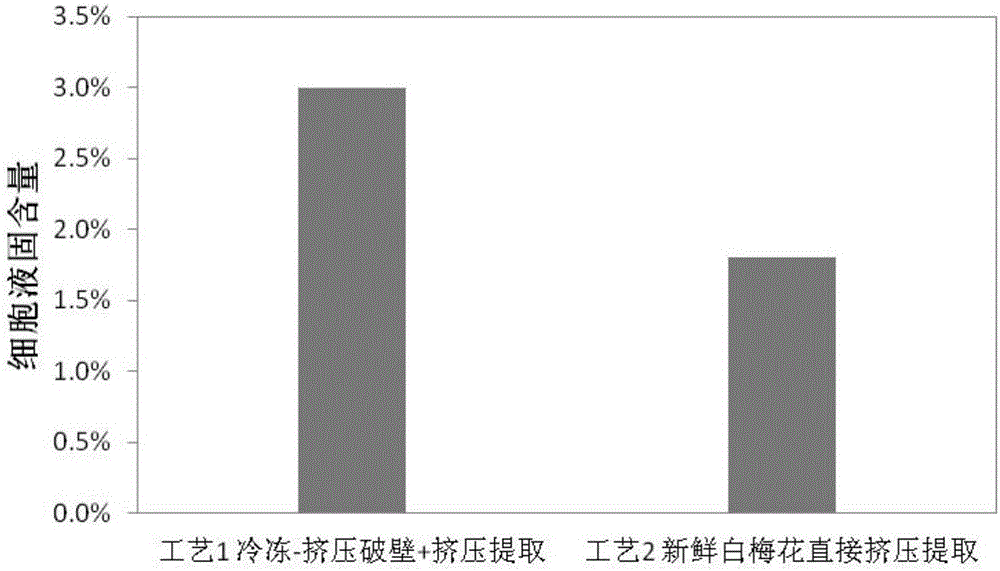

[0055] Embodiment two: different processing method cell fluid yield and solid content comparison

[0056] See attached figure 2 And attached image 3 :

[0057] Process 1: Take 1Kg of fresh white plum blossoms, freeze at -20°C for 12 hours, take them out and crush them by screw extrusion immediately, add 0.6Kg deionized water to the white plum blossom mud, stir for 5 minutes; carry out screw extrusion extraction, and centrifuge the obtained solution at 3000rpm for 5 minutes, The clarified white plum flower cell fluid was obtained, and the cell fluid yield was calculated to be 75.2%, and the solid content of the cell fluid was 3.0%.

[0058] Process 2: Take 1Kg of fresh white plum flowers, add 0.6Kg of deionized water, stir for 5 minutes; carry out screw extrusion extraction, and centrifuge the obtained solution at 3000rpm for 5 minutes to obtain clear white plum flower cell fluid. After calculation, the cell fluid yield is 56.7% , The cell liquid-solid content is 1.8%.

Embodiment 3

[0059] Embodiment three: Chlorogenic acid yield of different processing methods

[0060] See attached Figure 4 :

[0061] Process 3: Take 1Kg of fresh white plum blossoms (tested water content is 82.5%), freeze at -20°C for 12 hours, take it out and crush it by screw extrusion immediately, add 2Kg of deionized water to the white plum blossom mud, stir for 5 minutes; carry out screw extrusion After extraction, the obtained solution was centrifuged at 3000rpm for 5min to obtain a clarified white plum flower cell fluid, and the yield of chlorogenic acid was 4.6% (based on dry raw materials) through test and calculation.

[0062] Process 4: Take 200g of dried white plum blossoms (tested water content is 12.6%), pulverize, pass through a 40-mesh sieve, add 2.8Kg of deionized water, boil and extract for 1 hour; carry out screw extrusion extraction, and centrifuge the obtained solution at 3000rpm After 5 minutes, the clarified white plum flower cell fluid was obtained, and the yie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com