Chitosan modified mesoporous material as well as preparation method and application thereof

A technology of mesoporous materials and chitosan, which is applied in the field of chitosan-modified mesoporous materials, can solve the problems of cumbersome preparation process and high preparation cost, and achieve the effects of wide sources, reduced processing costs and abundant raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

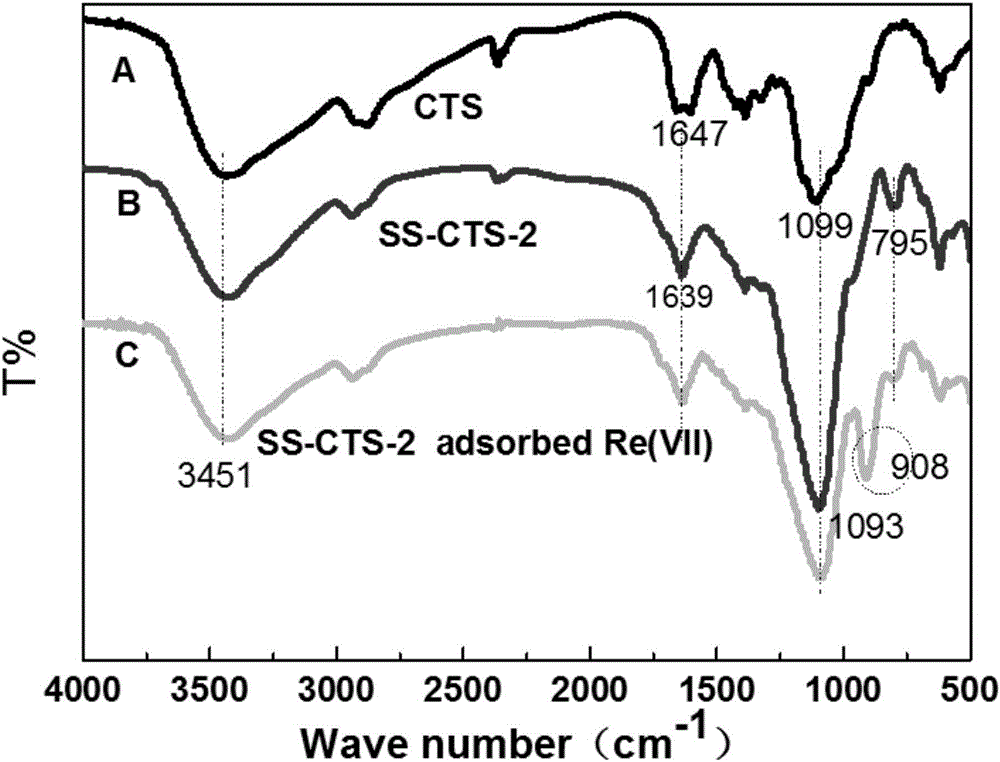

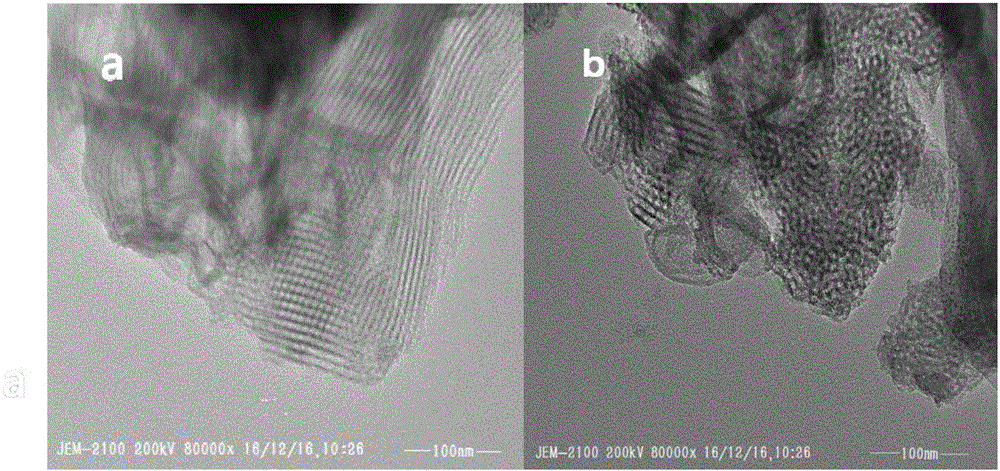

[0034] Embodiment 1 A kind of chitosan modified mesoporous material

[0035] (1) The preparation method is as follows:

[0036] 1) Add 4.0g P123 to 120g H 2 O and 20mL of concentrated hydrochloric acid (37wt%) solution, stirring and dissolving to clarity, to obtain solution A;

[0037] 2) Then a certain amount of Na 2 SiO 3 9H 2 O solution (5g Na 2 SiO 3 9H 2 O dissolved in 5g H 2 O, that is, the Na 2 SiO 39H 2 O solution), was slowly dropped into solution A, and after reacting for 1h under stirring at 40°C, solution B was obtained;

[0038] 3) Slowly drop a certain amount of Na into solution B 2 SiO 3 9H 2 O solution (5.5g Na 2 SiO 3 9H 2 O dissolved in 5.5g H 2 O, that is, the Na 2 SiO 3 9H 2 O solution), reacted for 1.5h to obtain solution C;

[0039] 4) Dissolve 2g of chitosan CTS in 2wt% acetic acid solution to obtain a chitosan solution; add the chitosan solution into solution C, stir well and drop in 15mL of glutaraldehyde Glu (25wt%) to react for ...

Embodiment 2

[0045] Example 2: During the preparation of chitosan-modified mesoporous materials, the effect of changing the amount of chitosan added on the rhenium adsorption effect in the solution

[0046] In the preparation process of the chitosan-modified mesoporous material, only the amount of chitosan CTS in step 4) was changed, and the other steps were the same as in Example 1. That is, 0.5 g, 1 g, 2 g, and 3 g of CTS were weighed and dissolved in an acetic acid (2 wt %) solution to obtain a chitosan solution, and finally a chitosan-modified mesoporous material was obtained.

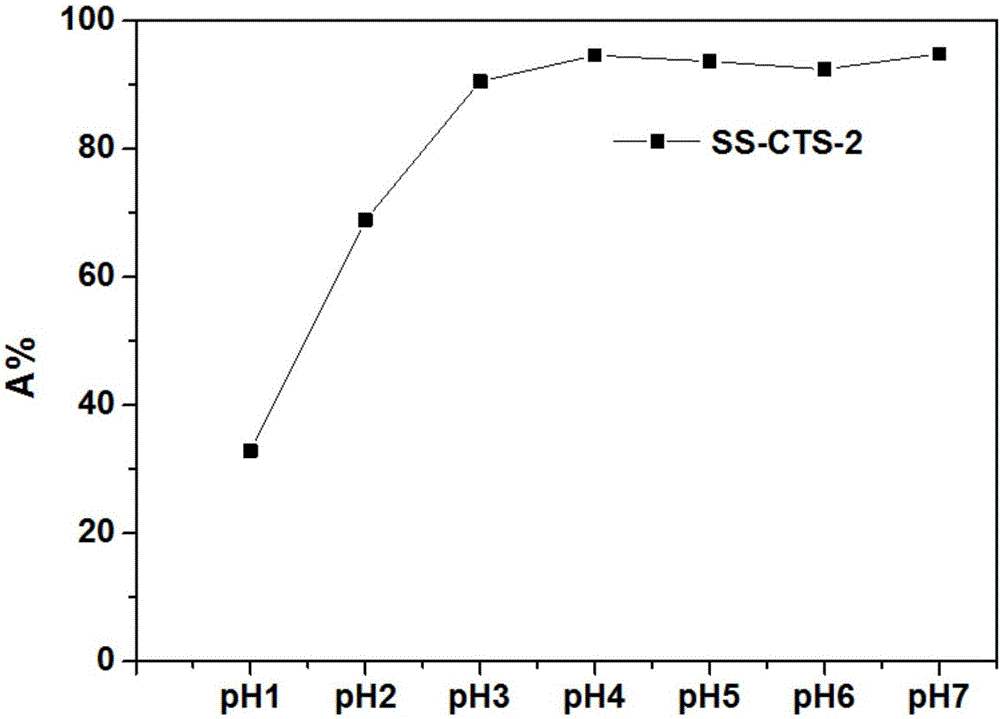

[0047] Take above-mentioned 10mg chitosan mesoporous material respectively as adsorbent and add the solution of different pH (pH=1,2,3,4,5,6,7) 20ppm Re(VII), it is shaken in box with 180r / min, shaking at 30°C for 24h.

[0048] Depend on Figure 5 It can be seen that when the chitosan mesoporous composite adsorbent is pH ≥ 3, the silicon source (Na 2 SiO 3 9H 2 When the mass ratio of O) to chitosan CTS is...

Embodiment 3

[0049] Example 3 Influence of chitosan-modified mesoporous material on the adsorption effect in solution under the condition of changing the amount of glutaraldehyde in the preparation process

[0050] During the preparation of the chitosan-modified mesoporous material, only the amount of glutaraldehyde in step 4) was changed, and other steps were the same as in Example 1. That is, 10 mL, 15 mL, and 20 mL of glutaraldehyde (25 wt %) solutions were added dropwise to finally prepare chitosan-modified mesoporous materials.

[0051] Take above-mentioned 10mg chitosan mesoporous material respectively as adsorbent and add the solution of different pH (pH=1,2,3,4,5,6,7) 20ppm Re(VII), it is shaken in box with 180r / min, shaking at 30°C for 24h.

[0052] Depend on Image 6 Visible, chitosan mesoporous composite adsorbent, under the condition of pH ≥ 3, low concentration rhenium solution, when the mass ratio of CTS and 25wt% Glu is 1:7.95-10.6, the adsorption effect of the prepared a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com