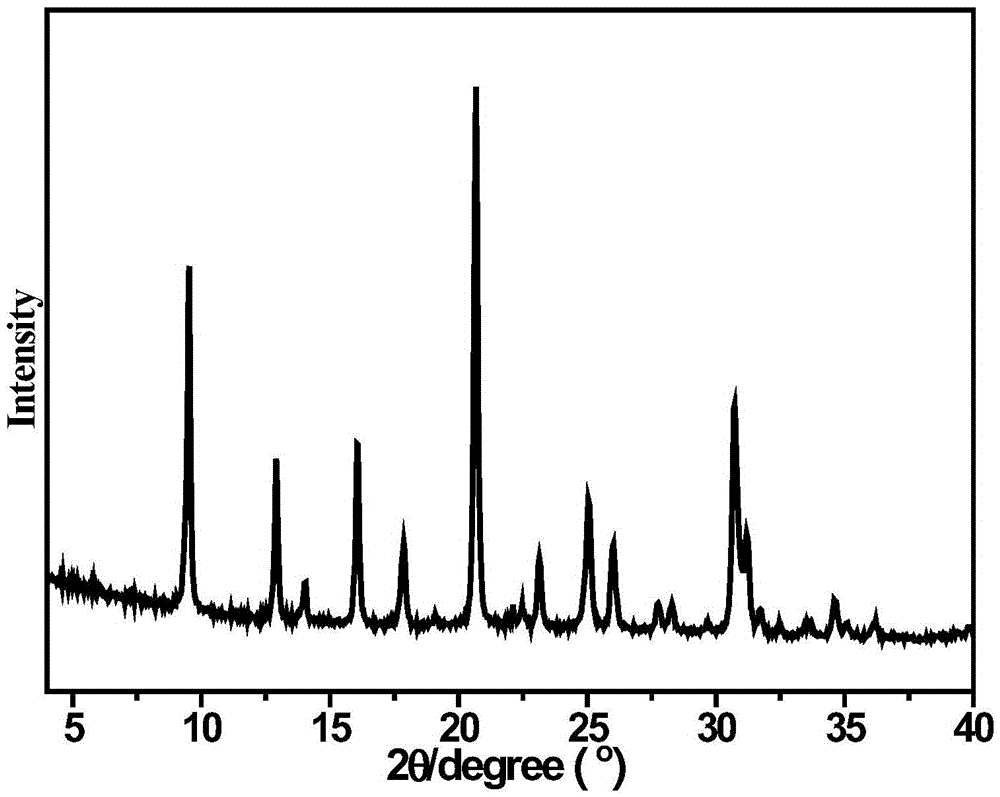

Ni-SSZ-13 catalyst, preparation method and application thereof

A technology of catalyst and solvent, which is applied in the field of Ni-SSZ-13 catalyst, preparation and application, which can solve the problems of uneven dispersion of loaded nickel metal, low catalyst stability, high preparation cost, etc., and achieve thermal and hydrothermal stability Strong performance, good stability, and wide adjustable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Synthesis of silicon-aluminum CHA molecular sieve materials using nickel amine chelate as a template (directing) agent.

[0040] Weigh 86.98g of aluminum nitrate [Al(NO 3 ) 3 9H 2 O, 0.23mol] was dissolved in 269.1mL of deionized water, after stirring evenly, 178.52g of Ni-TEPA chelate (made by nickel salt and tetraethylenepentamine, n(Ni:TEPA=1:1)) was added, After fully stirring, 49.57g of sodium hydroxide [NaOH, 1.05mol] was added to the above solution to adjust the pH value of the solution between 7 and 8, and 162.5g of silica sol [SiO 2 , 30wt%, 0.84mol], airtight and vigorously stirred until evenly mixed, and after complete mixing, the crystallized mixture was placed in a polytetrafluoroethylene-lined pressure vessel and crystallized at 180°C for 12h, and the product was filtered and washed , after washing, dry at 80°C for 12h, then raise the temperature to 600°C, and roast at constant temperature for 6h to obtain the product, which is denoted as NS-1. The stoi...

Embodiment 2

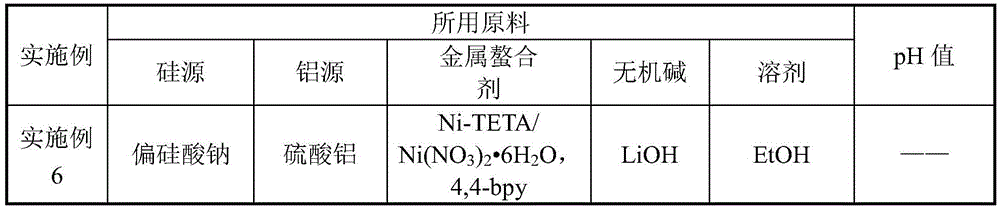

[0042] Synthesis of silicon-aluminum CHA molecular sieve materials using nickel amine chelate as a template (directing) agent.

[0043] Take by weighing 2211.98g of aluminum sulfate [[Al 2 (SO 4 ) 3 18H 2 O, purity ≥98wt.%, 3.32mol] dissolved in 21219.6mL deionized water and 1230.6mL N,N-dimethylformamide [DMF] after stirring evenly, add 651.66g nickel sulfate [NiSO 4 ·6H 2 O, 8.28mol] and 365.5g of triethylenetetramine [TETA, 2.5mol] were fully stirred, then 198.75g of lithium hydroxide [LiOH, 4.97mol] was added to the above solution to adjust the pH value of the solution between 9 and 10, and stirred Add 19836.4g silica sol [SiO 2 , 40wt%, 132.24mol], airtight and vigorously stirred until uniformly mixed, and after complete mixing, the crystallized mixture was placed in a polytetrafluoroethylene-lined pressure vessel and crystallized at 160°C for 3 days, and the product was filtered and washed , after washing, dry at 100°C for 8h, then raise the temperature to 500°C, a...

Embodiment 3

[0045] Synthesis of silicon-aluminum CHA molecular sieve materials using nickel amine chelate as a template (directing) agent.

[0046] Weigh 6.18g of sodium aluminate [NaAlO 2 , 0.08mol] dissolved in 49.1mL deionized water, after stirring evenly, add 8.92g nickel nitrate [Ni(NO 3 ) 2 ·6H 2 O, 0.04mol] and 6.24g of diethylenetriamine [DETA, 0.06mol] were fully stirred, then 5.57g of sodium hydroxide [NaOH, 0.14mol] was added to the above solution to adjust the pH value of the solution between 8 and 9, and stirred Add 26.71g of silica sol (50wt%, 0.22mmol) in the state, and stir vigorously in an airtight place until the mixture is uniform. After the mixture is completely uniform, the crystallized mixture is placed in a Teflon-lined pressure vessel and crystallized at 130°C for 7 days. , the product was filtered and washed, dried at 90°C for 6h after washing, then heated to 550°C, and roasted at a constant temperature for 6h to obtain the product, which was recorded as NS-3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com