Cobalt-nitrogen-carbon core-shell hybridization hollow porous carbon sphere preparation method

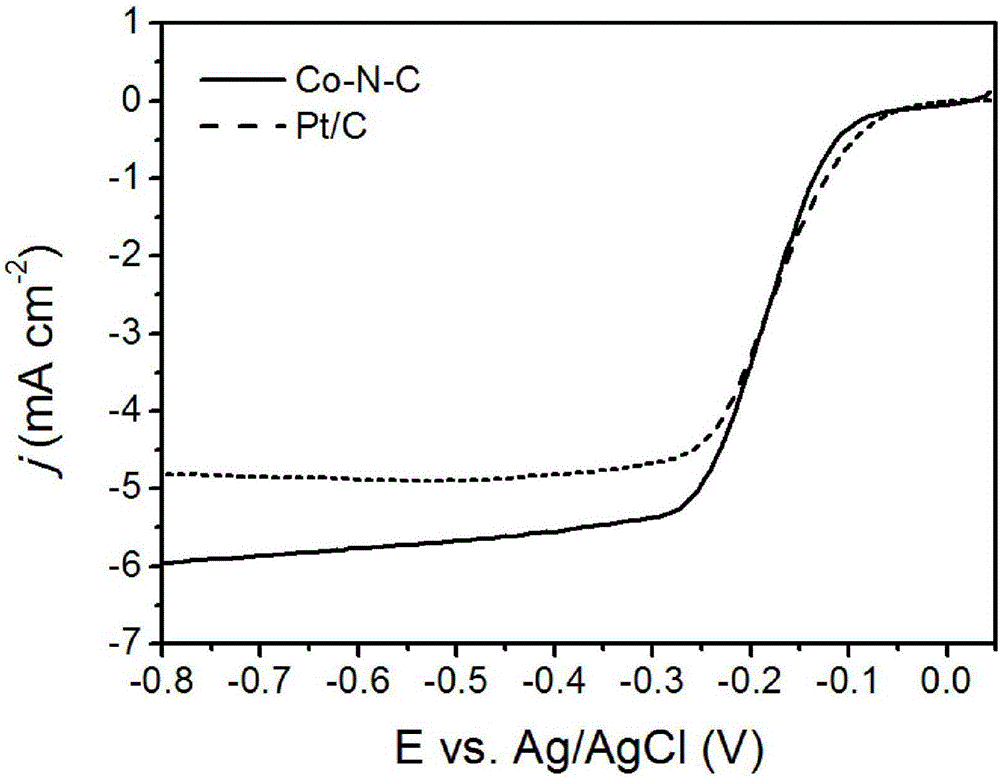

A hollow porous, carbon core-shell technology, applied in metal processing equipment, coating, transportation and packaging, etc., can solve the problems of complex preparation process and achieve excellent electrocatalytic performance, high conductivity and good shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

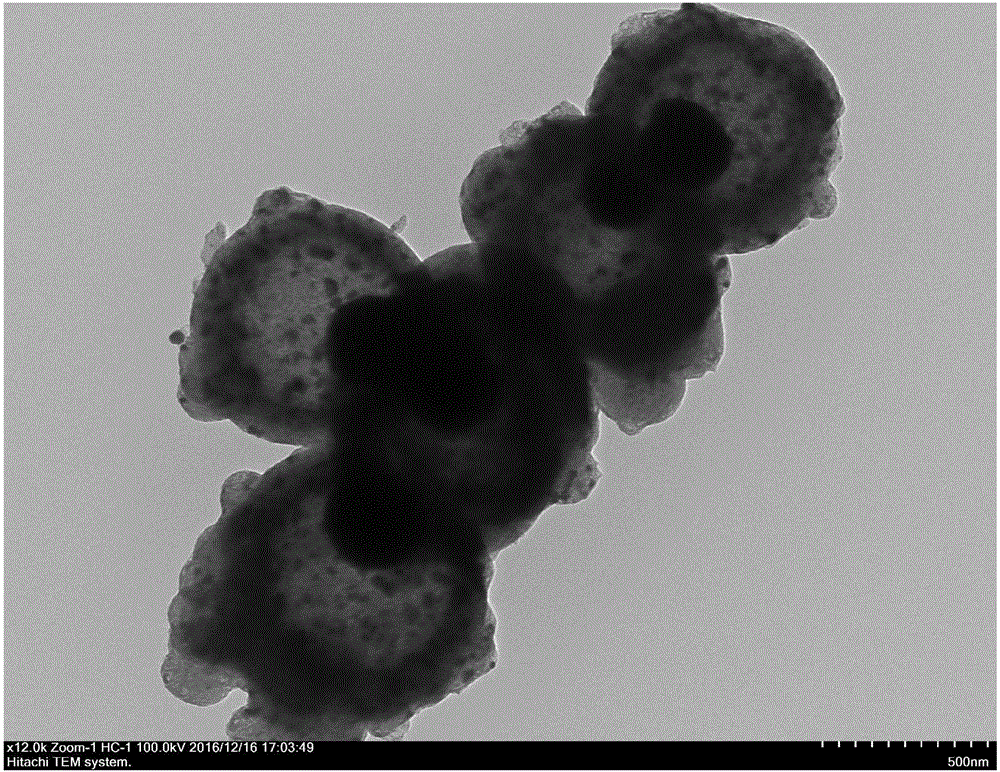

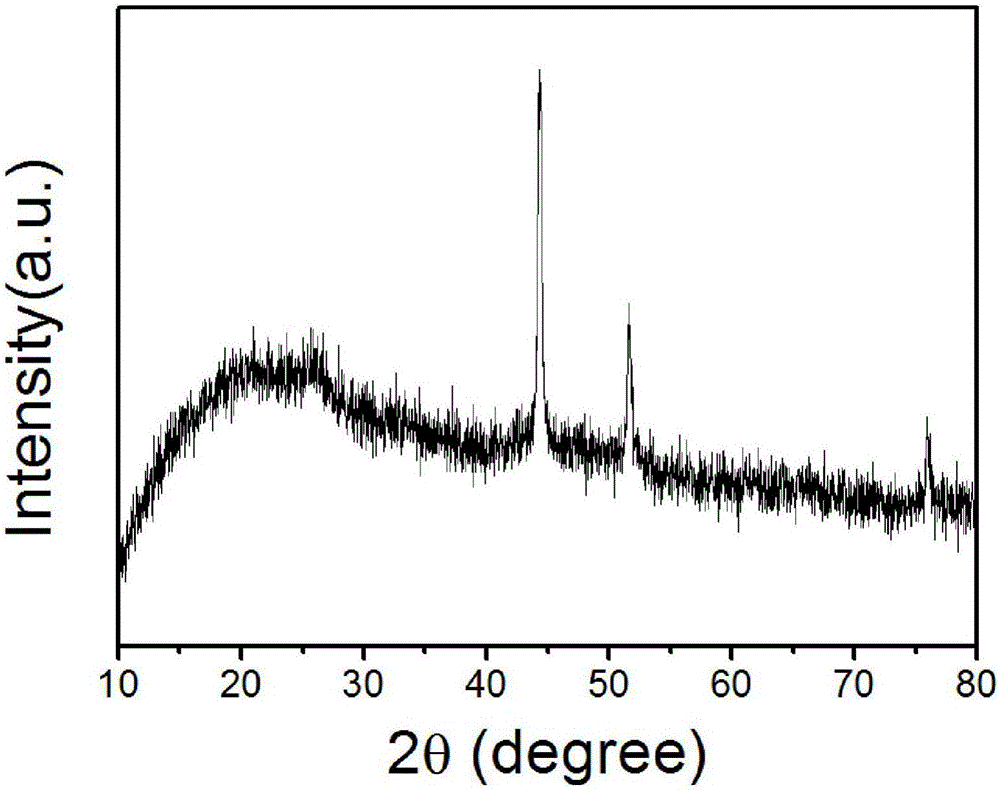

[0027] The preparation method of cobalt-nitrogen-carbon core-shell hybrid hollow porous carbon spheres in this example is as follows:

[0028] 1. Add 0.36g of cobalt nitrate into a mixed solution of 23mL of glycerin and 67mL of isopropanol, stir for 0.5h and pour it into a 100mL reaction kettle, then raise the temperature of the reaction kettle from room temperature to 180°C and keep it warm for 6h, centrifuge and wash with ethanol , obtaining cobalt precursor spheres, the diameter of the cobalt precursor spheres being 200-500nm;

[0029] 2. Evenly disperse the cobalt precursor spheres obtained in step 1 in 50mL of deionized water, add 50mg of dopamine and 0.05g of cobalt chloride, stir at room temperature for 12h, centrifuge (8000rpm, 5min), and use deionized water to collect the solid After washing with water for 3 times and drying, the Co@PDA composite microspheres can be obtained;

[0030] 3. Put the Co@PDA composite microspheres prepared in step 2 in a tube furnace, rais...

Embodiment 2

[0033] The preparation method of cobalt-nitrogen-carbon core-shell hybrid hollow porous carbon spheres in this example is as follows:

[0034] 1. Add 0.36g of cobalt nitrate into a mixed solution of 23mL of glycerin and 67mL of isopropanol, stir for 0.5h and pour it into a 100mL reaction kettle, then raise the temperature of the reaction kettle from room temperature to 180°C and keep it warm for 6h, centrifuge and wash with ethanol , obtaining cobalt precursor spheres, the diameter of the cobalt precursor spheres being 200-500nm;

[0035] 2. Evenly disperse the cobalt precursor spheres obtained in step 1 in 50 mL of deionized water, add 100 mg of dopamine and 0.1 g of cobalt chloride, stir at room temperature for 12 h, centrifuge (8000 rpm, 5 min), and use deionized water to collect the solid After washing with water for 3 times and drying, the Co@PDA composite microspheres can be obtained;

[0036] 3. Put the Co@PDA composite microspheres prepared in step 2 in a tube furnace...

Embodiment 3

[0039] The preparation method of cobalt-nitrogen-carbon core-shell hybrid hollow porous carbon spheres in this example is as follows:

[0040] 1. Add 0.36g of cobalt nitrate into a mixed solution of 23mL of glycerin and 67mL of isopropanol, stir for 0.5h and pour it into a 100mL reaction kettle, then raise the temperature of the reaction kettle from room temperature to 180°C and keep it warm for 6h, centrifuge and wash with ethanol , obtaining cobalt precursor spheres, the diameter of the cobalt precursor spheres being 200-500nm;

[0041] 2. Evenly disperse the cobalt precursor spheres obtained in step 1 in 50 mL of deionized water, add 200 mg of dopamine and 0.16 g of cobalt chloride, stir at room temperature for 12 h, centrifuge (8000 rpm, 5 min), and use deionized water to collect the solid After washing with water for 3 times and drying, the Co@PDA composite microspheres can be obtained;

[0042] 3. Put the Co@PDA composite microspheres prepared in step 2 in a tube furnac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com