Method for treating 6-nitrate wastewater by aid of electrolysis joint processes

A combined process and wastewater technology, applied in water/sewage treatment, chemical instruments and methods, neutralized water/sewage treatment, etc., can solve problems such as easy termination, high CODcr, high concentration, etc., to improve treatment efficiency and degradation efficiency , the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

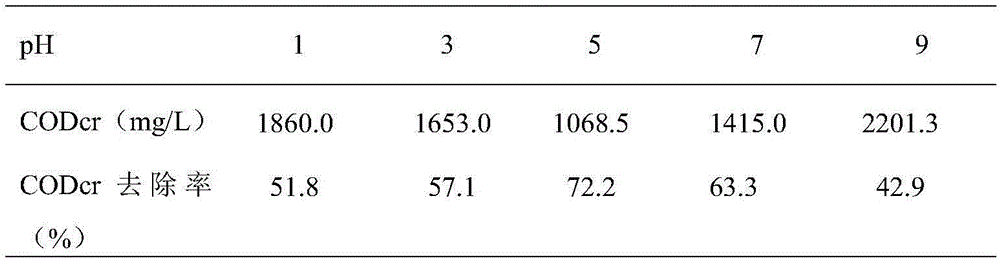

[0029] The CODcr of the 6-nitrate wastewater measured by the potassium dichromate method is 18873mg / L, and the chromaticity of the wastewater is determined to be 2600 to 3000 times by the dilution factor method. It can be seen that the wastewater is the same as the general organic dye wastewater, with high chromaticity and Difficult to biodegradable characteristics.

[0030] 1. Pretreatment of 6-nitrate wastewater

[0031] Use calcium carbide slag to adjust the above 6-nitrate wastewater to pH 6-7, add 25-30g / L polyaluminum chloride and 10-20g / L cetyl under the condition of stirring speed of 200-300r / min Trimethylammonium bromide pretreated the 6-nitrate wastewater and carried out suction filtration. The CODcr value of the treated wastewater was measured to be 3856.6 mg / L by the potassium dichromate method.

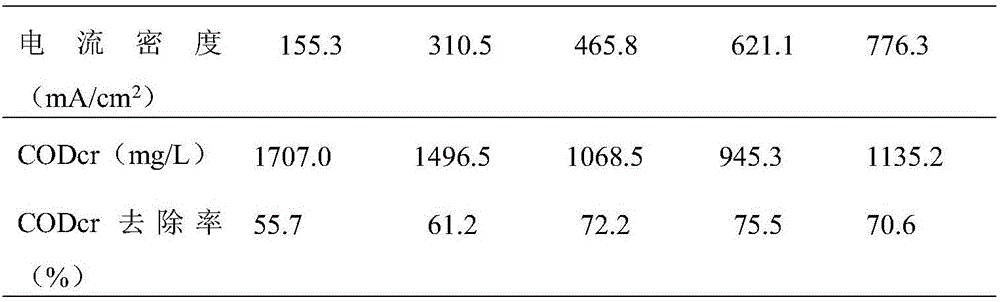

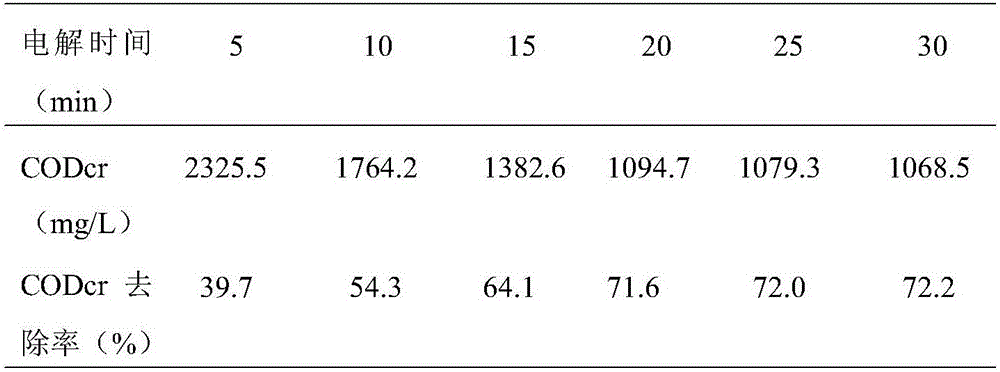

[0032] 2. Further treatment of 6-nitrate wastewater by electrocatalytic oxidation

[0033] (1) Substrate pretreatment

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com