Culture wastewater resourceful concentration and recycling device and technology

A technology for aquaculture wastewater and recovery devices, applied in chemical instruments and methods, water pollutants, waste fuels, etc., can solve the problem of poor retention of volatile solutes, poor retention of volatile solutes, and difficulty in meeting discharge standards for water quality and other issues to achieve full utilization, reduce energy consumption, and avoid loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

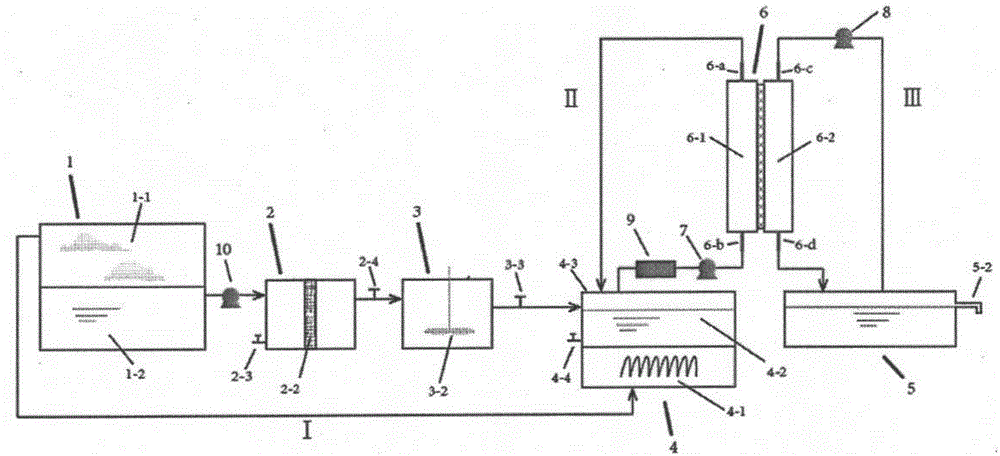

[0029] Such as figure 1 As shown, the aquaculture wastewater resource concentration and recovery device of the present invention includes an anaerobic reactor 1 , a filter tank 2 , an alkalinity adjustment tank 3 , a preheating tank 4 , a condensation circulation tank 5 and a membrane distillation unit 6 .

[0030] The anaerobic reactor 1 has a biogas slurry outlet and a biogas outlet, and the biogas slurry outlet is directly connected to the filter pond 2, and the biogas 1-1 is directly introduced into the biogas heater of the preheating pond 4 through the biogas gas supply pipeline 1, and the biogas slurry 1-2 is Preheat.

[0031] The filter tank 2 is provided with a grid or a filter screen 2-2 to intercept fine particles or suspended matter, reduce pollution in the subsequent membrane treatment process, and prolong the use time of the membrane distillation process. The biogas slurry outlet of the filter tank 2 is connected to the alkalinity adjustment tank 3, and the filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com