Oil-resistant hydrophobic antimicrobial ceramic tile for kitchen and preparation process thereof

A ceramic tile and hydrophobic technology, which is applied in the field of construction engineering, can solve the problems of difficult removal of oil stains on the surface of ceramic tiles, weakened time period, and lack of long-term purification, and achieves the effects of preventing oil stains, strong adhesion and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

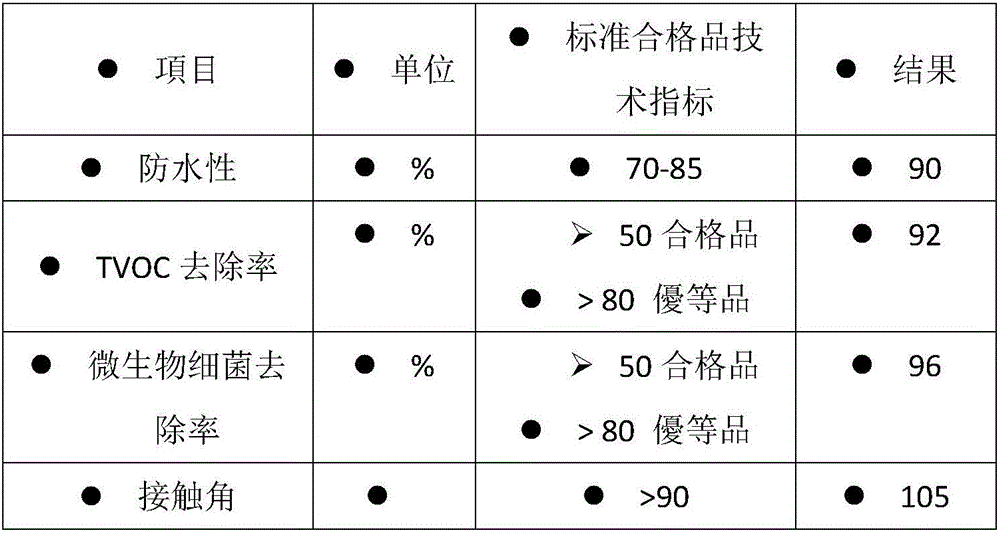

Image

Examples

Embodiment 1

[0050] The preparation process of oil-repellent, hydrophobic and antibacterial ceramic tiles comprises the following steps:

[0051] Mix kaolin, quartz and feldspar in a mass ratio of 60:40:30 and put them into a ball mill for ball milling for 32 hours, spray granulation, and age for 24 hours to obtain a body layer; spray decorative glaze. The green body material is put into a mold, pressed and formed under a pressure of 190Mpa to obtain a ceramic tile green body, and the decorative glaze is applied to the ceramic tile green body by an inkjet printing process. Fired at 1250°C for 60min.

[0052]To prepare the nano-oil-repellent and hydrophobic functional layer, add the organic polymer fluorocarbon material, ultra-dispersed nano-titanium dioxide, and silane coupling agent to the alcohol-water mixed solution in a ratio of 1:10:0.5 (alcohol-water ratio is 2:8), and ball mill for 24 hours .

[0053] Immerse the fired ceramic tile body in the functional solution for 30 minutes, a...

Embodiment 2

[0055] The preparation process of oil-repellent, hydrophobic and antibacterial ceramic tiles comprises the following steps:

[0056] Mix kaolin, quartz and feldspar in a mass ratio of 60:40:30 and put them into a ball mill for ball milling for 32 hours, spray granulation, and age for 24 hours to obtain a body layer; spray decorative glaze. The green body material is put into a mold, pressed and formed under a pressure of 190Mpa to obtain a ceramic tile green body, and the decorative glaze is applied to the ceramic tile green body by an inkjet printing process. Fired at 1250°C for 60min.

[0057] To prepare the nano-oil-repellent and hydrophobic functional layer, organic polymer fluorocarbon material, ultra-dispersed nano-titanium dioxide, and silane coupling agent are added to the alcohol-water mixed solution in a ratio of 0.5:15:1 (alcohol-water ratio is 1:9), and ball milled for 30 hours .

[0058] Immerse the fired ceramic tile body in the functional solution for 60 minut...

Embodiment 3

[0060] The preparation process of oil-repellent, hydrophobic and antibacterial ceramic tiles comprises the following steps:

[0061] Mix kaolin, quartz and feldspar in a mass ratio of 60:40:30 and put them into a ball mill for ball milling for 32 hours, spray granulation, and age for 24 hours to obtain a body layer; spray decorative glaze. The green body material is put into a mold, pressed and formed under a pressure of 190Mpa to obtain a ceramic tile green body, and the decorative glaze is applied to the ceramic tile green body by an inkjet printing process. Fired at 1250°C for 60min.

[0062] To prepare the nano oil-repellent and hydrophobic functional layer, the organic polymer fluorocarbon material, ultra-dispersed nano-titanium dioxide, and silane coupling agent are added to the alcohol-water mixed solution in the ratio of 2:15:1.5 (alcohol-water ratio is 3:7), and the medium ball mill 48h.

[0063] Immerse the fired ceramic tile body in the functional solution for 30 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com