Preparation method of high-purity difluoroethanol

A difluoroethanol and high-purity technology is applied in the field of preparation of high-purity difluoroethanol, which can solve the problems of high pollution, flammability and explosion, hinder the industrialization of difluoroethanol and the like, and achieve the effect of less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

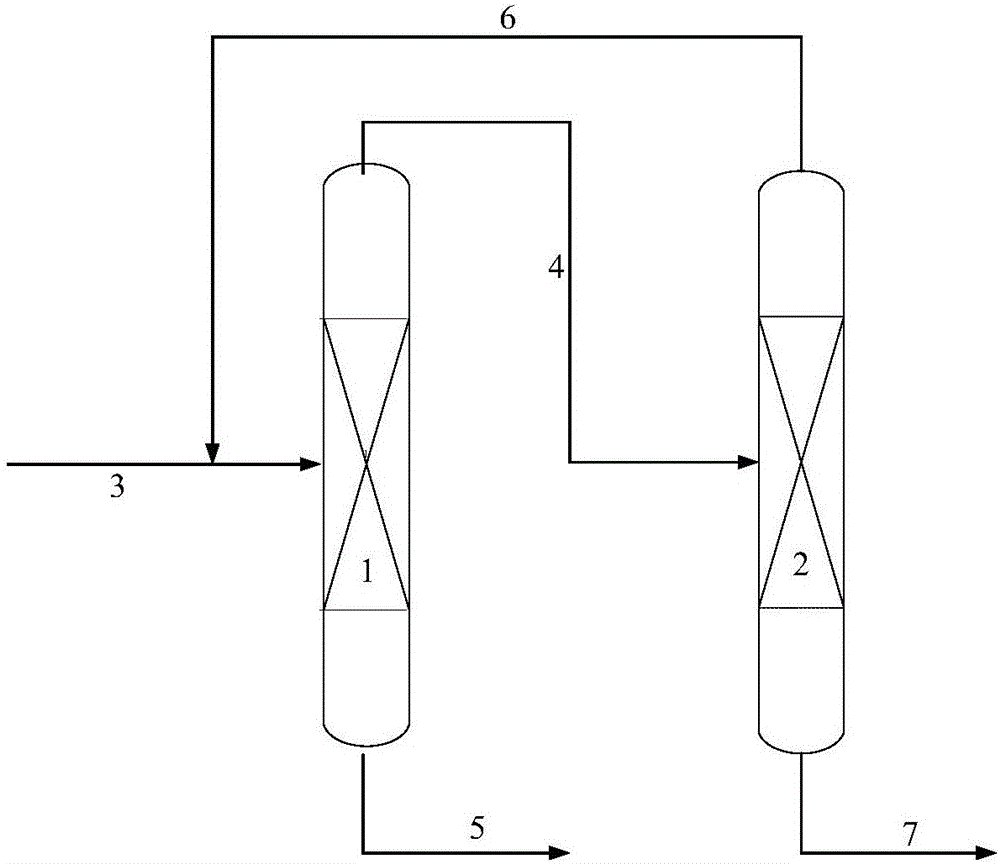

[0021] The aqueous solution with a mass fraction of difluoroethanol of 80% enters the first packed rectification tower for separation, and the overhead distillate is the azeotrope of difluoroethanol / water with a higher difluoroethanol content, and the difluoroethanol fraction is water, and the first packed rectification The overhead fraction of the distillation tower enters the second packed rectification tower for separation, and the overhead fraction is an azeotrope of difluoroethanol / water with a lower difluoroethanol content, which is circulated to the first packed rectification tower, and the bottom fraction is Difluoroethanol.

[0022] The operating parameters of the first packed rectification tower and the second packed rectification tower in Example 1 are shown in Table 1, and the stream composition is shown in Table 2.

[0023] Operating parameter in the embodiment 1 of table 1

[0024] Distillation column The first packed distillation column The second...

Embodiment 2

[0028] The operation process of Example 2 is shown in Example 1, the operating parameters of the first packed rectification tower and the second packed rectification tower are shown in Table 3, and the stream composition is shown in Table 4.

[0029] Operating parameter in the embodiment 2 of table 3

[0030] Distillation column The first packed distillation column The second packed distillation column Operating pressure / kPa(A) 50 150 Tower top temperature / ℃ 25 103 Tower kettle temperature / ℃ 33 106 Reflux ratio 10 10

[0031] The logistics composition in the embodiment 2 of table 4

[0032] Material / mass fraction 3 5 7 water 5% 99.88% 0.01% Difluoroethanol 95% 0.12% 99.99%

Embodiment 3

[0034] The operation process of Example 3 is shown in Example 1, the operating parameters of the first packed rectification tower and the second packed rectification tower are shown in Table 5, and the stream composition is shown in Table 6.

[0035] Operating parameters in table 5 embodiment 3

[0036] Distillation column The first packed distillation column The second packed distillation column Operating pressure / kPa(A) 30 100 Tower top temperature / ℃ 50 92 Tower kettle temperature / ℃ 77 95 Reflux ratio 4.2 5.5

[0037] The logistics composition in the embodiment 3 of table 6

[0038] Material / mass fraction 3 5 7 water 10% 99.85% 0.01% Difluoroethanol 90% 0.15% 99.99%

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com