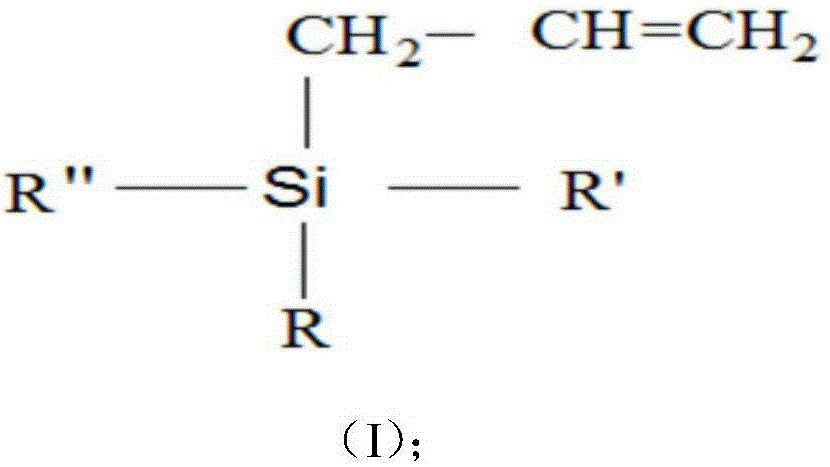

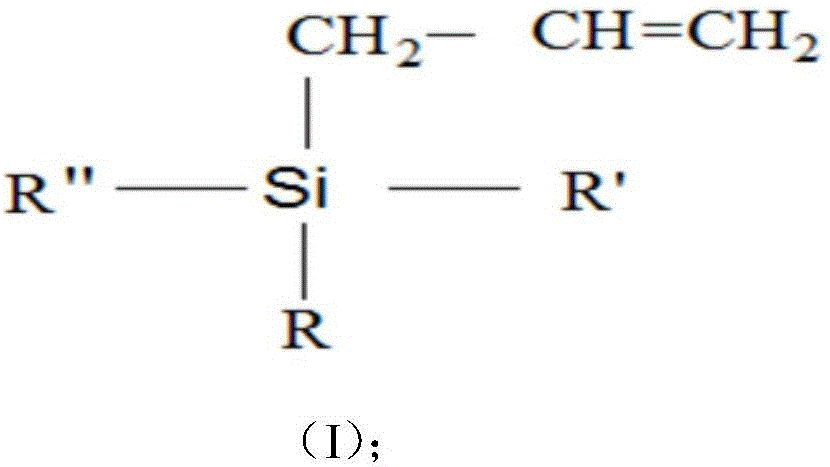

Preparation method for allyl silane

A technology of allyl silane and alkyl, which is applied in the field of polymer synthesis, can solve problems such as unfavorable safety application, high production cost, and potential safety hazards, and achieve the effects of reducing costs, reducing equipment load, and avoiding production hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In a 250ml four-neck glass round bottom flask equipped with a reflux condenser, thermometer, stirrer, heater and balance feeder, under nitrogen protection, add 15 grams of magnesium chips, 25 grams of chloropropene, and 65 grams of methyl trimethoxy base silane and 0.2 g of iodine, heated to reflux for 4.5 hours, began to drop the remaining 20 g of chloropropene, and added them all in one hour. After adding, keep warm for 30 minutes to end the reaction. The analysis result of the reaction liquid showed that the yield of methyldiallylmethoxysilane was 89.55%.

Embodiment 2

[0033] In a 250ml four-neck glass round-bottomed flask equipped with a reflux condenser, thermometer, stirrer, heater and balance feeder, under nitrogen protection, add 23 grams of magnesium chips, 35 grams of chloropropene, and 110 grams of methyltrimethoxy base silane and 0.55 g of potassium iodide, heated to reflux for 4.5 hours, began to drop the remaining 30 g of chloropropene, and added them all in one hour. After adding, keep warm for 30 minutes to end the reaction. The analysis result of the reaction liquid showed that the yield of methallyldimethoxysilane was 92.75%.

Embodiment 3

[0035] In a 250ml four-neck glass round bottom flask equipped with a reflux condenser, thermometer, stirrer, heater and balance feeder, under nitrogen protection, add 10 grams of magnesium chips, 21 grams of chloropropene, 50 grams of dimethyl di Methoxysilane and a mixture of 0.6 g of iodine and potassium iodide (potassium iodide accounts for 30-55%) were heated to reflux for 5 hours, and the remaining 10 g of chloropropene was added dropwise, and the addition was completed within one hour. After adding, keep warm for 30 minutes to end the reaction. The analysis result of the reaction liquid showed that the yield of dimethylallylmethoxysilane was 91.51%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com