Photo/thermal grading response shape memory polymer as well as preparation method and application thereof

A memory polymer and shape-responsive technology, which is applied in the field of photo/thermal graded response shape memory polymer and its preparation, can solve problems such as temperature limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The second embodiment of the present invention provides a method for preparing the above-mentioned photo / thermal graded response shape memory polymer, comprising the following steps:

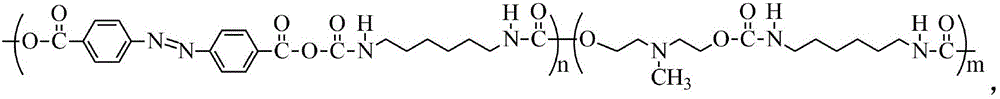

[0028] Polymerizing monomer A and monomer B to obtain a shape memory polymer prepolymer containing azobenzene structural units;

[0029] Add monomer C and monomer B into the shape memory polymer prepolymer to obtain the high molecular weight shape memory polymer.

[0030] The preparation method of the light / heat graded response shape memory polymer provided by the second embodiment of the present invention uses azobenzenedicarboxylic acid, diisocyanate and N-methyldiethanolamine as raw materials for polymerization synthesis. First, azobenzenedicarboxylic acid and part of diisocyanate are alternately copolymerized to construct the soft segment chain of azobenzene. The catalyst for the reaction of said azobenzenedicarboxylic acid and diisocyanate is dibutyltin dilaurate; N-methyldiethanolam...

Embodiment 1

[0038] Add 0.37g 4,4'-azobenzenedicarboxylic acid and 10.0g N,N'-dimethylformamide into a three-neck flask to dissolve; then add dropwise 1.5g hexamethylene diisocyanate, 0.6mL dilauric acid Dibutyltin, react at 80°C for 30min; then add 1.96g of N-methyldiethanolamine and 1.5g of hexamethylene diisocyanate, and react at 80°C for another 30min; after the reaction is completed, pour the solution into a polytetrafluoroethylene mold, The light / heat graded response shape memory polyurethane (LHSMPU) was obtained by drying in an air-blast drying oven at 80°C for 24 hours. The azobenzene structural unit is introduced into the main chain of polyurethane, which has the function of photoresponse. The polyurethane hard segment provides physical crosslinking points for thermal recovery, and the azobenzene structure can also undergo structural changes under the action of thermal stimulation, causing the main chain to move, elastic recovery occurs, and return to the initial state.

Embodiment 2

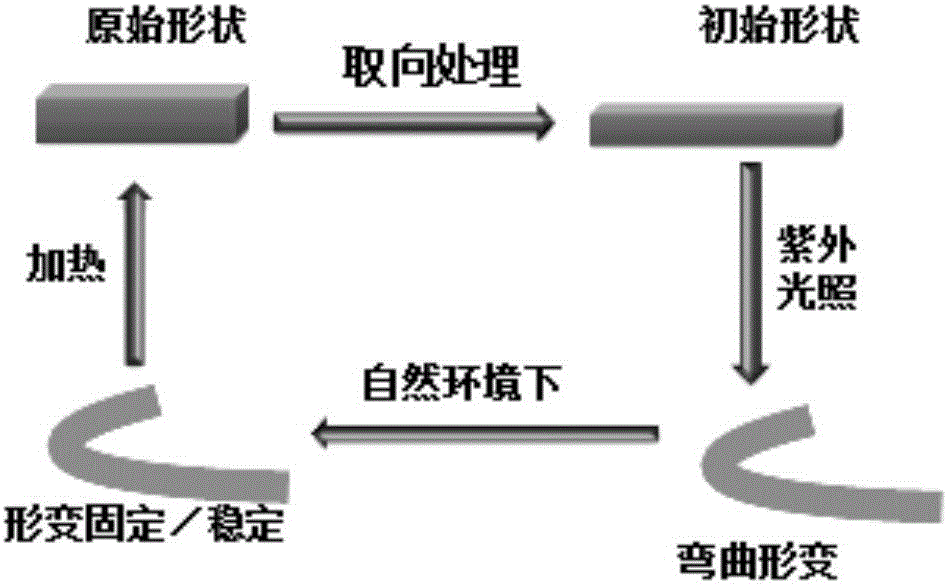

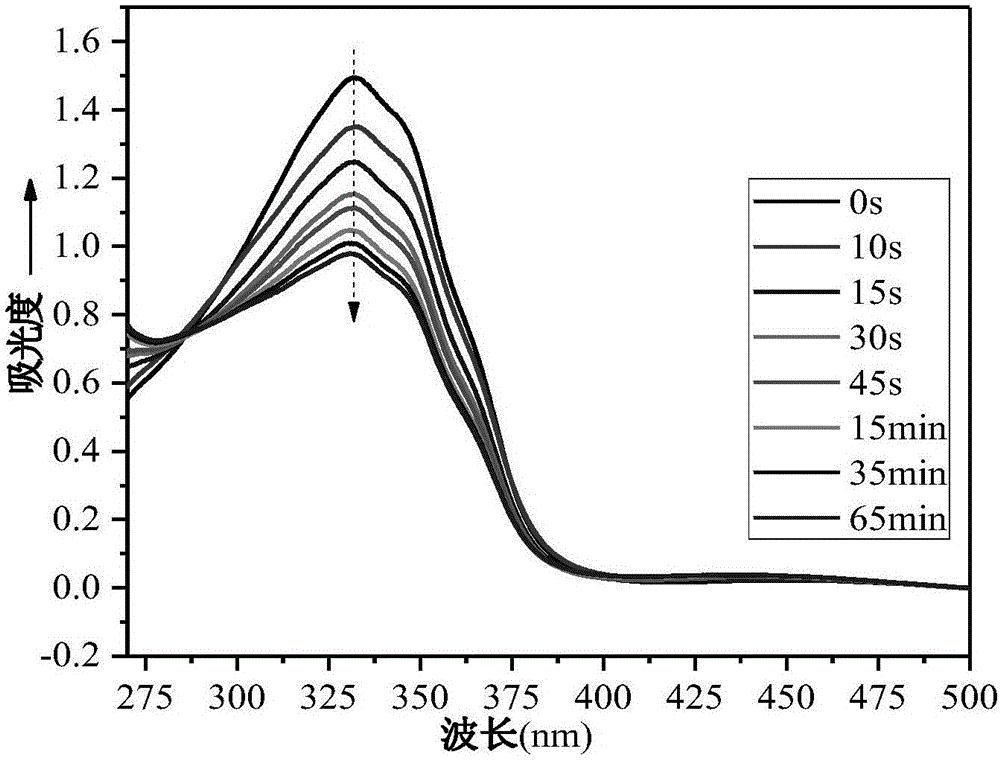

[0040] Add 0.54g of 4,4'-azobenzenedicarboxylic acid and 12.0g of N,N'-dimethylformamide into a three-necked flask to dissolve; then add dropwise 1.5g of hexamethylene diisocyanate, 0.6mL of dilauric acid Dibutyltin, react at 80°C for 30min; then add 1.89g N-methyldiethanolamine, 1.5g hexamethylene diisocyanate, and react at 80°C for another 30min; after the reaction is completed, pour the solution into a polytetrafluoroethylene mold , baked in an air-blast drying oven at 80°C for 24 hours to obtain light / heat graded response shape memory polyurethane (LHSMPU). figure 1 It is a schematic diagram of the photo / thermal graded response shape change and recovery process of the prepared LHSMPU. from figure 1 It can be seen in the figure that under the irradiation of ultraviolet light, the main chain of polyurethane curls and has photoinduced shape deformation; after the ultraviolet light stops, the curly shape remains stable at room temperature and has a good shape fixation functio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com