Surface control agent and preparation method thereof

A technology of surface control agent and round-bottomed flask, applied in coating, epoxy resin coating and other directions, can solve the problem of uneven coating surface, and achieve the effect of improving flatness, reducing surface tension difference and reducing friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Exemplary embodiments will be described in detail here, and the implementations described in the following exemplary embodiments do not represent all implementations consistent with the present invention. Rather, they are only examples of methods consistent with some aspects of the invention as detailed in the appended claims.

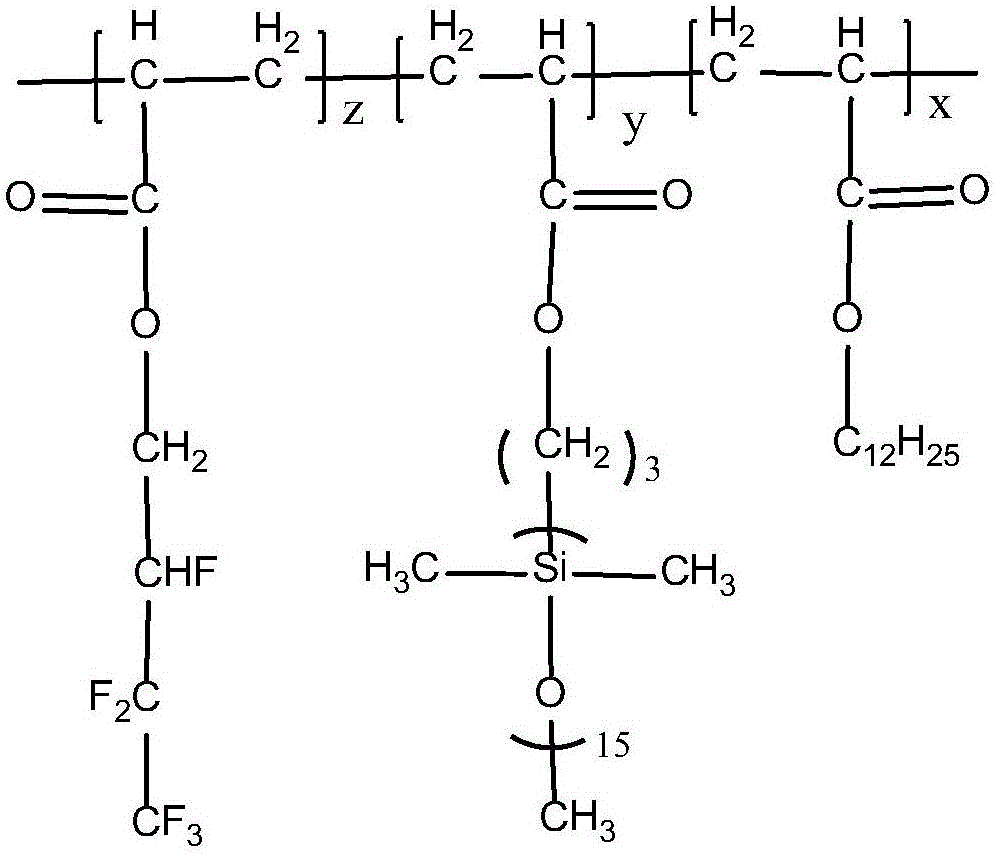

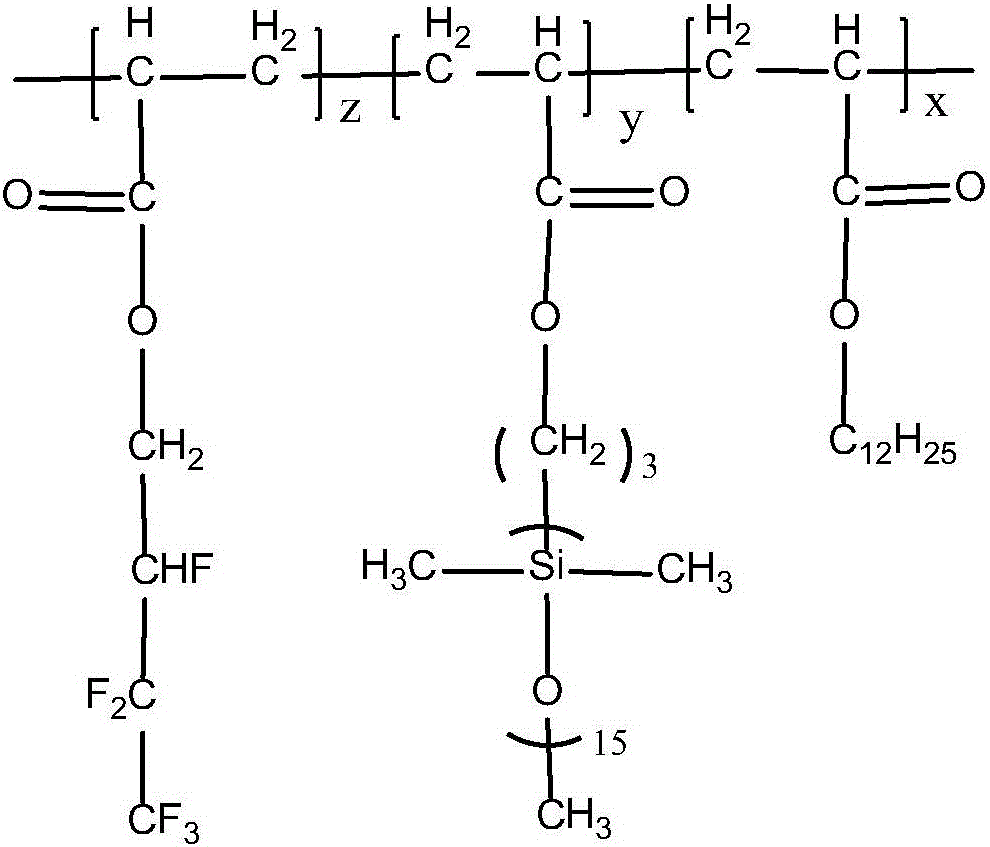

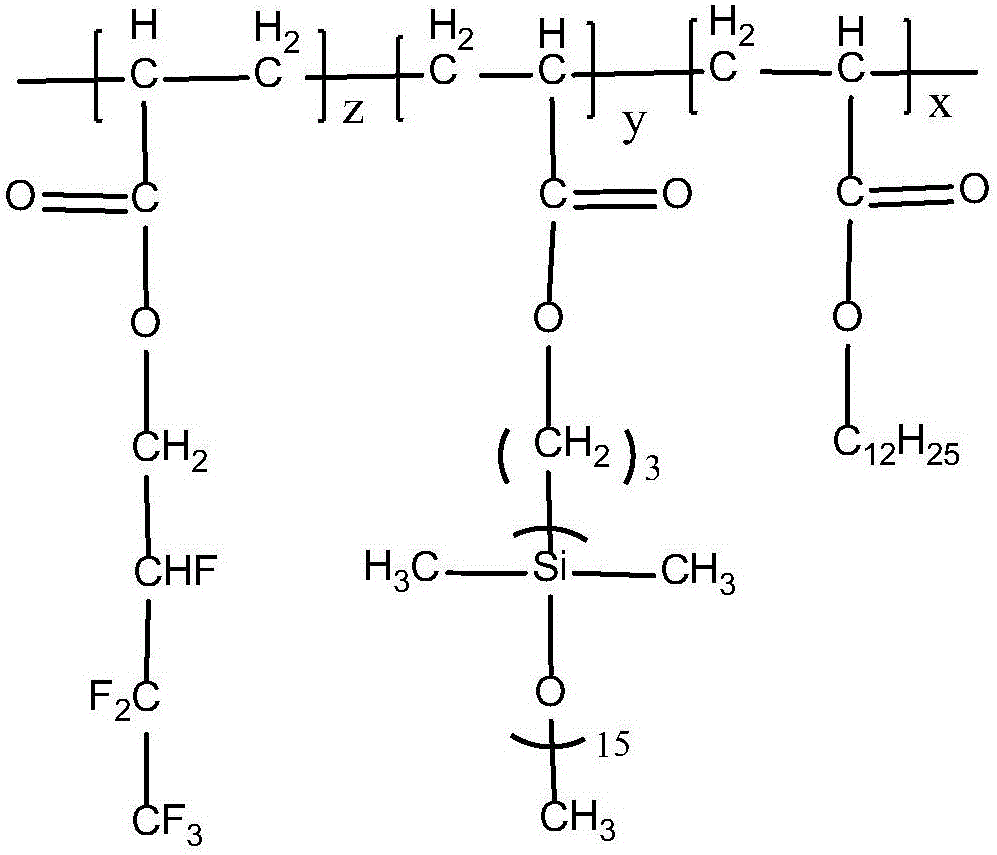

[0018] The embodiment of the present invention discloses a surface control agent, the surface control agent is hexafluorobutyl acrylate, lauryl acrylate and CH 2 =CH-COO-(CH 2 ) 3 -[-Si(CH 3 ) 2 -O-] 15 -CH 3 Three monomers are used as polymerization units. According to the catalyst regeneration controllable polymerization mechanism, the fluorine-containing acrylate block copolymer containing silicone is obtained by copolymerization, and its structural formula is:

[0019]

[0020] Wherein, x, y, and z are all integers greater than or equal to 1.

[0021] The embodiment of the present invention also provides a method for preparing a surface control age...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com