Environment-friendly single-component silylated polyether sealant for vehicle and preparation method thereof

A technology of silane polyether and silane-modified polyether, which is applied in the field of environment-friendly single-component silane polyether sealant for vehicles and its preparation, can solve the problems of inability to meet the needs of high-end vehicles, inappropriate formula ratios, and environmental protection. The performance cannot be achieved and other problems, and the production process method is simple, the practicability is strong, and the decoration performance is excellent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

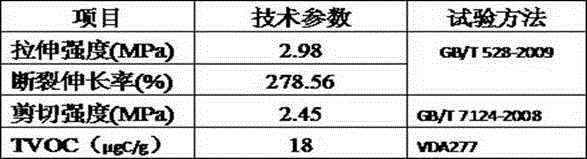

Embodiment 1

[0054]Prepare the environment-friendly single-component silane polyether sealant for vehicles with the following formula and process:

[0055] Weigh 500g of nano-active calcium carbonate, 100g of heavy calcium carbonate, 500g of light calcium carbonate, 50g of fumed silica, 50g of titanium dioxide, 10g of 1010 type anti-aging agent, 4g of N-220 white carbon black, and 4g of Tinuvin326 type ultraviolet absorber Put 10g of agent, Tinuvin770 light stabilizer and 10g of heat stabilizer together into a double planetary mixer, heat to 120°C, under the protection of dry inert gas, mix for dehydration pretreatment, stir slowly (25-50rPm) for 120 minutes; add S303H silane Modified polyether resin 1000g, DIDP plasticizer (diisodecyl phthalate) 150g, vacuumize and heat to 110°C, stir at high speed (1000rPm) for 150 minutes, cool down to 40°C, add A-171 silane 30g of dehydrating agent, stir slowly (250rpm) for 25 minutes, add 20g of silane coupling agent phenyltrimethoxysilane, stir slowl...

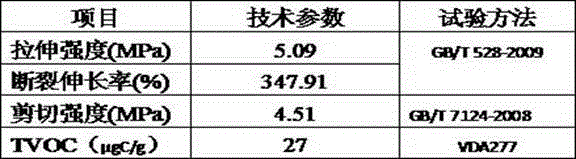

Embodiment 2

[0059] Prepare the environment-friendly single-component silane polyether sealant for vehicles with the following formula and process:

[0060] Weigh 300g of nano-active calcium carbonate, 100g of heavy calcium carbonate, 300g of light calcium carbonate, 100g of iron red, 10g of 1010 type anti-aging agent, 100g of N-220 white carbon black, 20g of Tinuvin326 type ultraviolet absorber, and 20g of Tinuvin770 type light stabilizer Add 20g of Tinunvin-68 heat stabilizer and 20g of Tinunvin-68 heat stabilizer together in a double planetary mixer, heat to 80°C, stir slowly (25-50rPm) for 120 minutes, add 200g of S203H silane-modified polyether resin, S303H silane-modified polyether Resin 800g, DIDP plasticizer 300g, vacuumize and heat to 120°C, high-speed stirring (1000rPm) for 150 minutes, cool down to 30°C, add A-171 silane water remover 30g, slowly stir (250rPm) for 25 minutes, add Silane coupling agent phenyltrimethoxysilane 20g, stir slowly (250rpm) for 25 minutes, add 60g of γ-...

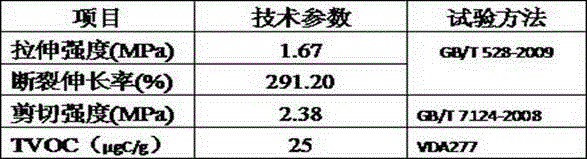

Embodiment 3

[0064] Prepare the environment-friendly single-component silane polyether sealant for vehicles with the following formula and process:

[0065] Weigh 1200g of nano-active calcium carbonate, 50g of titanium dioxide, 10g of 1010 type anti-aging agent, 4g of N-220 white carbon black, 10g of Tinuvin326 type ultraviolet absorber, 10g of Tinuvin770 type light stabilizer, and 10g of heat stabilizer and put them into a double planetary mixer , heated to 110°C, stirred slowly (25-50rPm) for 120 minutes; added 200g of S203H silane-modified polyether resin, 800g of S303H silane-modified polyether resin, 170g of DIDP plasticizer, vacuumed and heated to 110 ℃, high-speed stirring (1000rPm) for 150 minutes, cooling down to 40 ℃, adding 25g of VTMO type silane dewatering agent, stirring slowly (250rPm) for 25 minutes, adding 25g of silane coupling agent phenyltrimethoxysilane, stirring slowly (250rpm) After 25 minutes, add 50g of N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane adhesion crossl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com