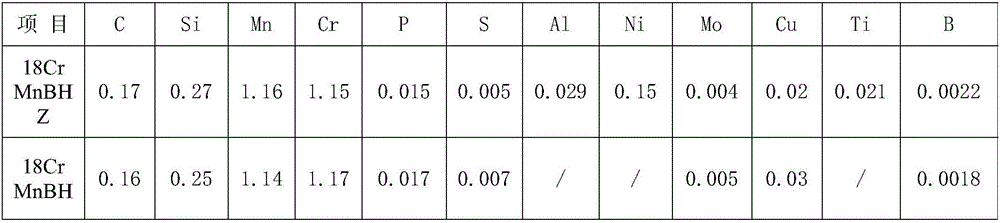

Automotive boron-containing high-grade gear steel and production process thereof

A production process, gear steel technology, applied in the field of metallurgy, can solve the problems of unstable hardenability, impact toughness comprehensive performance index is difficult to meet the use requirements of automobile factories, can not be effectively controlled, etc., to achieve the effect of improving hardenability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The high-grade boron-containing gear steel for automobiles described in the present invention is produced using the process route of "converter smelting→LF furnace refining→RH vacuum refining→soft argon blowing→continuous casting machine pouring→rolling":

[0028] Converter smelting

[0029] 1. The loading capacity of the converter with a nominal volume of 120t is 134.2t, including 121.5t of molten iron, 4.1t of scrap steel and 8.6t of pig iron. The carbon content at the end of the converter is 0.11%, and the tapping amount is 121.3t.

[0030] 2. Add 100kg of calcium carbide, 100kg of aluminum-iron (40% grade), 120kg of silicon-calcium-barium, the corresponding amount of ferroalloy, 700kg of refining slag, and 500kg of lime in the converter tapping process.

[0031] LF Furnace Refining

[0032] 1. After the molten steel enters the LF process, add 200 kg of nickel plates baked and dried by continuous casting red slabs. In the early stage of LF refining, use 60Kg of alu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com