Deck type arch bridge unbalanced horizontal rotation system and rotation construction method

A technology of balancing horizontal and rotating bodies, which is applied in the construction of arch bridges, bridges, bridges, etc., and can solve problems such as large project investment, high construction safety risks, and difficult quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

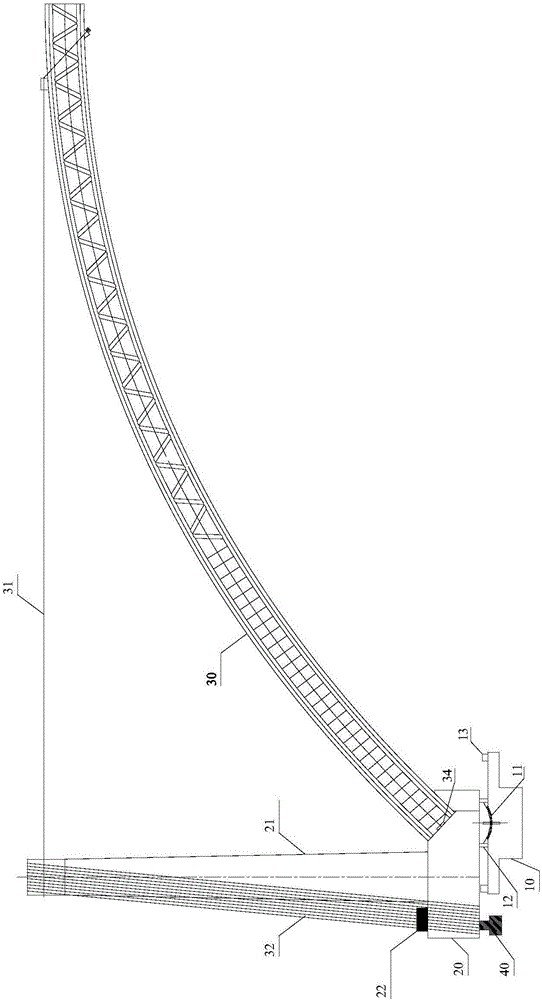

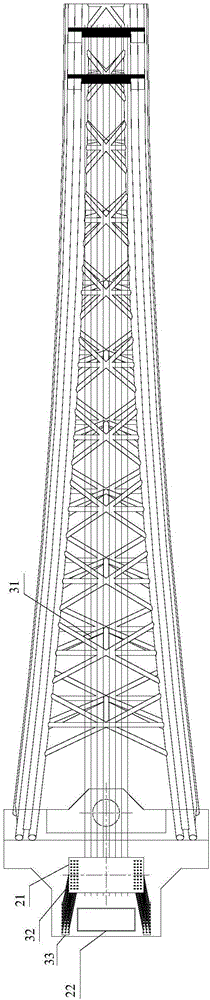

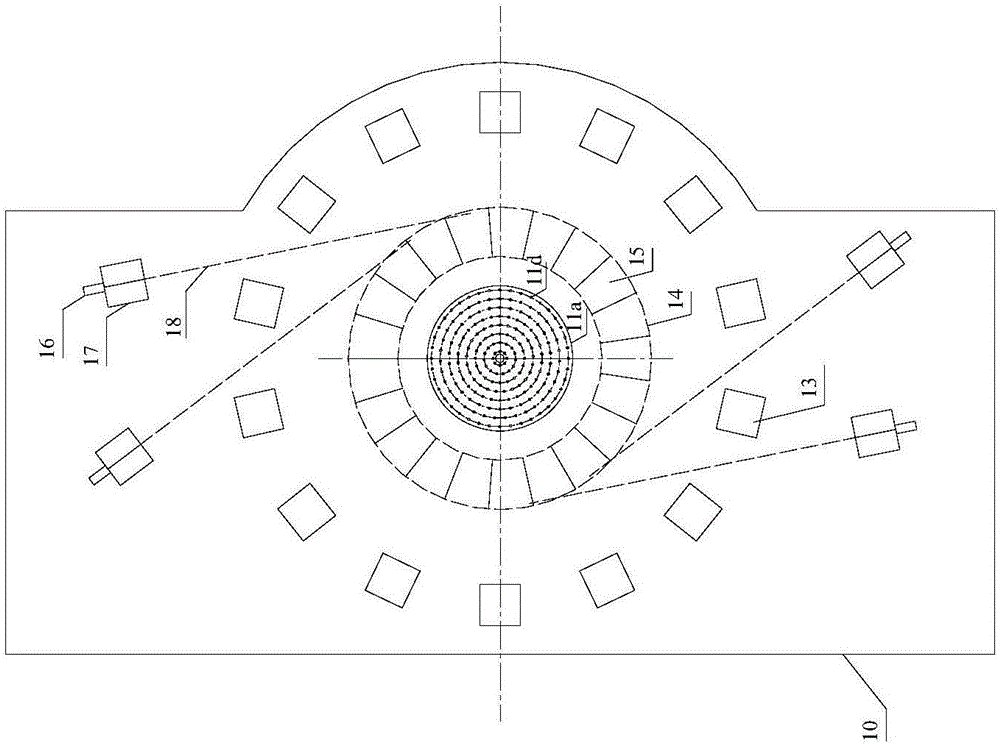

[0036] refer to figure 1 with figure 2 , an unbalanced horizontal swivel system of an overhead arch bridge of the present invention includes the following parts:

[0037] The bottom wall 10 doubles as the abutment foundation and is located on the foundation, on which an annular slideway 14, a jack reaction seat 13 and a traction reaction seat 17 are arranged. The lower wall 10 is the basis of the swivel structure, and after the swivel is completed, it is connected with the upper wall 20 to form the main arch foundation.

[0038] The upper wall 20 supports the junction pier 21 and the half-span main arch ring 30. The upper end of the back cable 32 is anchored to the top cap of the junction pier 21, and the lower end is anchored to the rear bottom of the upper wall 20. The half-span main arch ring 30 is suspended on the On the junction pier 21;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com